Izibuthe zeNeodymium zangokwezifiso

Ozibuthe be-neodymium bangokwezifiso ngokuya ngezidingo zenkampani yakho. Sithengisa wonke amamaki omazibuthe be-neodymium, ubujamo bangokwezifiso, osayizi kanye nokunameka

I-Neodymium Magnets Manufacturer, ifektri E-China

I-HuizhouI-Fullzen TechnologyUCo., Ltd unguchwephesheumkhiqizi kazibuthe we-neodymium, umenzi wemagnethi ngokwezifiso, ifektri, kanye nomhlinzeki eShayina kusukela ngo-2016. Singochwepheshe ekuhlolweni, ekuklameni, ekubunjiniyelani, ekukhiqizeni, ekuhloleni, nasekuhlanganiseni omamagnethi be-neodymium ngokwezifiso. Ukwenza ngokwezifiso ukuhlangabezana nezidingo zenkampani yakho. Sinikeza imikhiqizo ethengiswayo kanye nezinsizakalo ezenziwe ngokwezifiso, ukwakheka ngokwezifiso koomamagnethi abaphakade, omamagnethi be-neodymium ababunjwe ngokwezifiso, okwenzelwe imboni yakho.

Khetha Izibuthe zakho ze-Neodymium

Ividiyo ye-Neodymium magnetic

Isingeniso sikazibuthe we-Neodymium

I-Neodymium magnet, eyaziwa nangokuthi uzibuthe we-NdFeB, iyikristalu ye-Tetragonal crystal system eyakhiwe yi-Nd2Fe14B. Kuyimpahla kazibuthe eyenziwe ngensimbi ye-praseodymium neodymium ngokulungiswa nokucwiliswa. Lolu hlobo lukazibuthe luwuzibuthe unomphela ozibuthe wawo ungowesibili kuphela ku-Absolute zero holmium uzibuthe, futhi uwuzibuthe ovame ukusetshenziswa kakhulu we-Rare-earth.

Ukwakheka kwamakhemikhali kazibuthe we-Neodymium

Izinto ezihlala njalo ze-Neodymium iron boron magnet ziyizinto ezihlala njalo ze-magnet ezisekelwe ku-intermetallic compound Nd2Fe14B. Izingxenye eziyinhloko yizinto ezingavamile zomhlaba i-neodymium (Nd), i-iron (Fe), kanye ne-boron (B). I-real earth element eyinhloko yi-neodymium (Nd), engashintshwa kancane ngezinye izinsimbi ezingavamile zomhlaba ezifana ne-dysprosium (Dy) kanye ne-praseodymium (Pr) ukuze kutholakale izakhiwo ezahlukene. I-iron ingashintshwa kancane ngezinye izinsimbi ezifana ne-cobalt (Co) kanye ne-aluminium (Al). Okuqukethwe kwe-boron kuncane, kodwa kudlala indima ebalulekile ekwakhiweni kwesakhiwo se-tetragonal crystal compounds intermetallic, okwenza lezi zinhlanganisela zibe ne-magnetization ephezulu yokugcwala, i-anisotropy ephezulu ye-uniaxial, kanye nokushisa okuphezulu kwe-Curie.

Uzibuthe we-Neodymium Process flow

Ukugeleza kwenqubo:ukuxubha → ukuncibilika nokwenza ingot/ukuphonswa kwe-strip → ukwenza impushana → ukubumba → ukuthambisa nokuthambisa → ukuhlola kazibuthe → ukucubungula ukugaya → ukucutshungulwa kwephinikhodi → i-electroplating → umkhiqizo oqediwe. Izithako ziyisisekelo, futhi ukuthambisa nokuthambisa kuyisihluthulelo.

Amathuluzi okukhiqiza namathuluzi okuhlola ukusebenza kwezikhala kazibuthe ze-neodymium iron boron:kufaka phakathi isithando somlilo esincibilikayo, isithando somlilo esijikijelwa ngomugqa, umshini wokuchoboza, isigayo sokugeleza komoya, umshini wokubumba wokucindezelwa, umshini wokupakisha we-vacuum, umshini wokucindezela we-isostatic, isithando somlilo esishisayo, isithando somlilo sokushisa ukushisa, umhloli wokusebenza kazibuthe, imitha ye-Gaussian.

I-Neodymium iron boron magnet machining amathuluzi:ukugaya okungenasikhungo, umshini wokuzungeza, ukugaya okuphindwe kabili, ukugaya okuyisicaba, umshini wokusika, ukugaya okuphindwe kabili, ukusika ucingo, ukubhola kwebhentshi, ukugaya okungajwayelekile, njll.

Izinhlelo zokusebenza zikazibuthe ze-Neodymium

Izinto zikazibuthe ze-sintered neodymium iron boron unomphela zinezakhiwo ezinhle kazibuthe futhi zisetshenziswa kabanzi emikhakheni efana ne-elekthronikhi, imishini yamandla, imishini yezokwelapha, amathoyizi, ukupakisha, imishini yehadiwe, i-aerospace, njll. Ezivamile zihlanganisa amamotho kazibuthe ahlala unomphela, izipikha, izihlukanisi kazibuthe, amadrayivu wediski wekhompyutha, izinsimbi zemishini yokucabanga ye-resonance magnetic, njll.

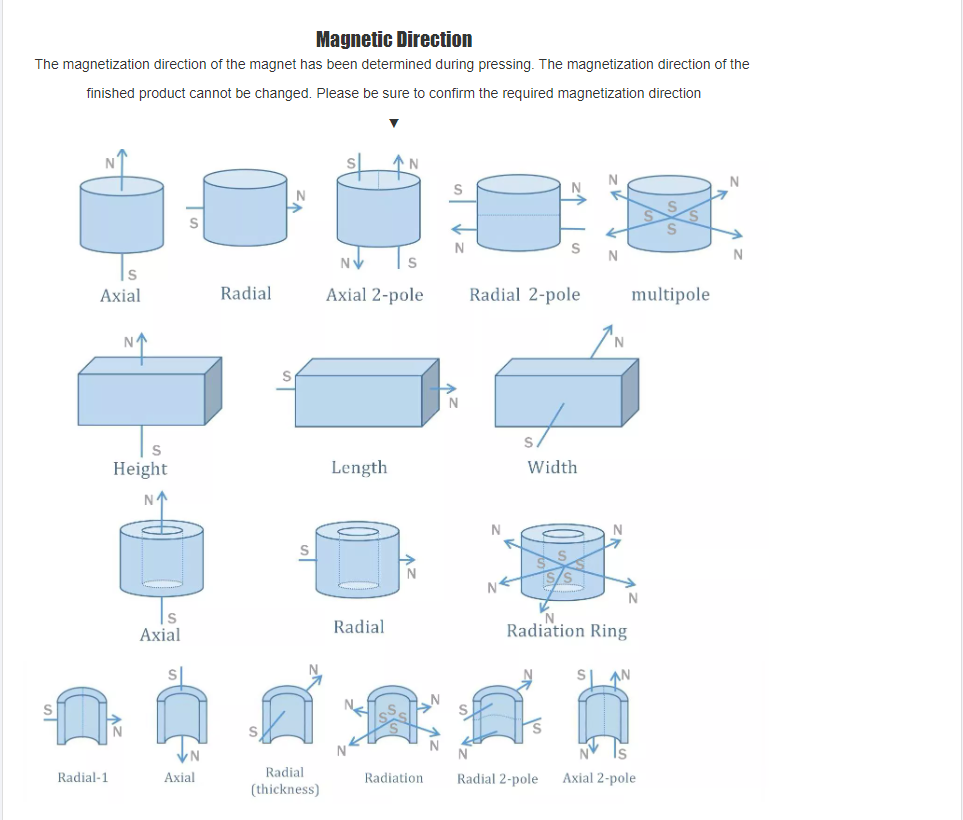

Neodymium uzibuthe isiqondiso uzibuthe futhienamathela ebusweni

Awukwazanga ukuthola okufunayo?

Ngokuvamile, kunezitokwe zozibuthe be-neodymium abavamile noma izinto zokusetshenziswa endaweni yethu yokugcina impahla. Kodwa uma unesidingo esikhethekile, siphinde sinikeze isevisi yokwenza ngokwezifiso. Samukela futhi i-OEM/ODM.

Izibuthe zeNeodymium zangokwezifiso

I-HuizhouI-Fullzen TechnologyI-Co., Ltd ingumkhiqizi ozibuthe ochwepheshile.Inkampani yethu yenza ngokwezifiso ozibuthe bomhlaba abayivelakancane futhi ingenye yabakhiqizi bezizibuthe bangokwezifiso abaphambili.Sikhethekile ekuhloleni, ekuklameni, kwezobunjiniyela, ekukhiqizeni, ekuhloleni nasekuhlanganiseniozibuthe we-neodymium ngokwezifiso. Ukwenza ngendlela oyifisayo ukuhlangabezana nezidingo zenkampani yakho.Njengoba umhlahlandlela wangokwezifiso olandelayo ubonisa, sithengisa omazibuthe be-neodymium abaphelele. Sinikezela ngemikhiqizo engekho eshalofini kanye nezinsiza ezenziwe ngokwezifiso, uzibuthe wangokwezifiso, owenzelwe imboni yakho. Njengozibuthe abakhulu be-neodymium arc abenzelwe wena.

Usayizi nomumo:

Singahlinzeka ngezifisoidiski, isilinda, indandatho, i-cube yesikwele, ibhulokhi elingunxande, i-arc, i-countersunk, ihuku namanye amamagnethi angapheli angajwayelekile.

Ukukhiqiza:

Sisebenzisa i-othomathikhiimishiniukusika nokugaya izinto zokusetshenziswa ukuze wenze ubukhulu bemagnethi ehlala njalo oyifunayo, ngokubekezelelana okuncane, ukuze kufezwe umphumela wokuqeda.

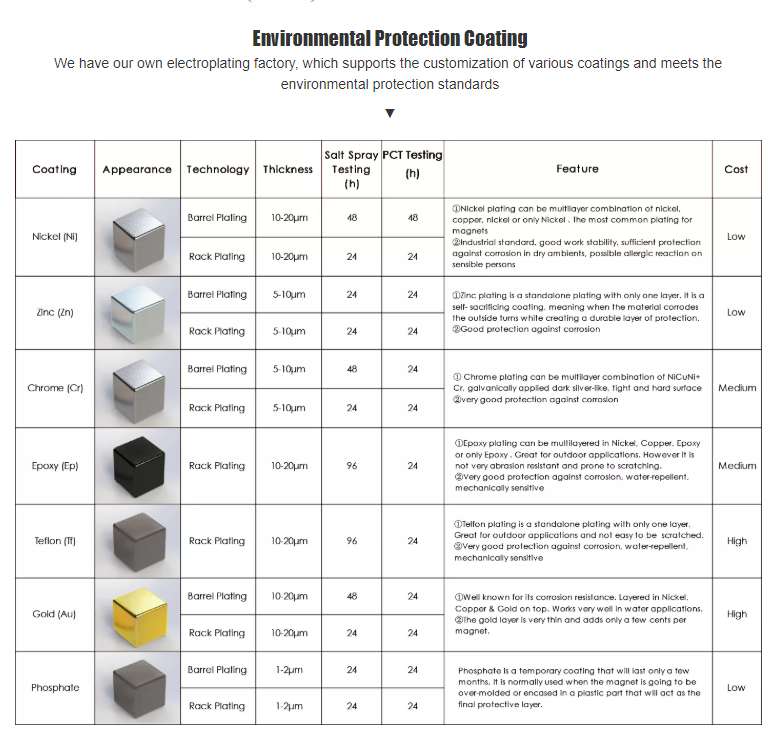

Ukwelashwa kwendawo:

Izibuthe ezihlala njalo kulula ukuba zenziwe nge-oxidized. Ngokwezidingo zamakhasimende, indawo engaphezulu izombozwa, ifakwe i-epoxy noma i-electroplated ukuvimbela ukugqwala. Singahlinzeka nge-nickel plating, i-galvanization, i-electrophoresis nezinye izinsizakalo.

Amanothi Okushisa:

Uzibuthe waphakade uzwela izinga lokushisa. Sizokwenza ngokuqinile ukukhiqiza ngokuvumelana nesidingo ikhasimende for odonsa unomphela nge high lokushisa ukumelana.

Umhlahlandlela ngokwezifiso

| Okubalulekile | I-Sintered Neodymium-Iron-Boron ( NdFeB ) | |

| Usayizi | Ngokwezifiso | |

| Isimo | Bukukhiya,Disc,Ci-ylinder,Bar,Ring, Cngaphandle, IngxenyeHkulungile,Cphezulu,Ti-rapezoid,Iizimo ezivamile, njll. | |

| Ukusebenza | N33 N35 N38 N40 N42 N45 N48 N50 N52N54 njll. | |

| Ukugqoka | Zn, Ni-Cu-Ni, Ni, Gold, Silver, Copper, Epoxy, Chrome, njll | |

| Ukubekezelela usayizi | ±0.05mm ku-diamater/ubukhulu, ±0.1mm ngobubanzi/ubude | |

| Uzibuthe | Ubukhulu bumagnetic, i-Axially Magnetized, i-Diametrally Magnetized, izigxobo eziningi zenziwe zibuthe, i-Radial Magnetized. (Izimfuneko ezithile ezenziwe ngokwezifiso zenziwe zibuthe) | |

| Ubukhulu. Izinga Lokushisa Lokusebenza | Ibanga | Ubukhulu. Izinga Lokushisa Lokusebenza |

| I-N35-N52 | 80°C (176°F) | |

| 33M- 48M | 100°C (212°F) | |

| 33H-48H | 120°C (248°F) | |

| 30SH-45SH | 150°C (302°F) | |

| 30UH-40UH | 180°C (356°F) | |

| 28EH-38EH | 200°C (392°F) | |

| 28AH-35AH | 220°C (428°F) | |

I-MOQ nesikhathi sokuhola

| Izingcezu | Isikhathi esiholayo |

| 1000-10000 | izinsuku ezingu-10 |

| 10000-100000 | izinsuku ezingu-20 |

| 100000-1000000 | izinsuku ezingu-30 |

Yini esingakunikeza yona...

Singabakhiqizi nabaphakeli be-Neodymium Magnet e-China. Singakhiqiza i-Neodymium Magnet (umazibuthe we-NdFeB) ngokwezidingo zakho.

Ukusebenza kwezibuthe

Kukhona ikakhulukazi amapharamitha amathathu alandelayo wokunquma ukusebenza kukazibuthe:

I-Remanence Br: Ngemva kokuthi umazibuthe unomphela enziwe uzibuthe ekugcwalisweni kwezobuchwepheshe kanye nenkundla kazibuthe yangaphandle isusiwe, i-Br egciniwe ibizwa ngokuthi induction eyinsalela kazibuthe.

Amandla okuphoqa i-Hc: Ukunciphisa u-B kazibuthe ongunaphakade owenziwe uzibuthe ekugcwalisweni kobuchwepheshe abe uziro, amandla adingekayo azibuthe ahlehlayo abizwa ngokuthi amandla kazibuthe okungenisa induction, esifushanisiwe njengamandla aphoqayo.

Umkhiqizo wamandla kazibuthe u-BH: Umele ukuminyana kwamandla kazibuthe okwakhiwa uzibuthe esikhaleni segebe lomoya (isikhala esiphakathi kwezigxobo kazibuthe ezimbili zikazibuthe), okungukuthi, amandla azibuthe amile weyunithi ngayinye yegebe lomoya. Njengoba la mandla elingana nomkhiqizo we-Bm ne-Hm kazibuthe, kubizwa ngokuthi umkhiqizo wamandla kazibuthe.

Singakwazi ukwenza ngokwezifiso omazibuthe abangapheli ngezakhiwo phakathiI-N35-N54emakethe.

Ipharamitha kaMazibuthe

| Ibanga | Remanence | Amandla Okuphoqa | I-Intrinsic Coercive Force | Maximum Energy Product | ITemp Esebenzayo | ||||

| Br | Hcb | Hcj | BH max | Tw | |||||

| mT | KGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | ||

| N35 | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 80℃ |

| N38 | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | 80℃ |

| N40 | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥955 | ≥12 | 302-326 | 38-41 | 80℃ |

| I-N42 | 1280-1320 | 12.8-13.2 | ≥923 | ≥11.6 | ≥955 | ≥12 | 318-342 | 40-43 | 80℃ |

| N45 | 1320-1370 | 13.2-13.7 | ≥876 | ≥11.0 | ≥955 | ≥12 | 342-366 | 43-46 | 80℃ |

| N48 | 1370-1420 | 13.7-14.2 | ≥892 | ≥11.2 | ≥955 | ≥12 | 366-390 | 46-49 | 80℃ |

| N50 | 1390-1440 | 13.9-14.4 | ≥836 | ≥10.5 | ≥955 | ≥12 | 374-406 | 47-51 | 80℃ |

| N52 | 1420-1470 | 14.2-14.7 | ≥836 | ≥10.5 | ≥876 | ≥11 | 390-422 | 49-53 | 80℃ |

| I-N55 | 1460-1520 | 14.6-15.2 | ≥716 | ≥9 | ≥876 | ≥11 | 414-446 | 52-56 | 80℃ |

| 35M | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 100 ℃ |

| 38M | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | 100 ℃ |

| 40M | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | 100 ℃ |

| 42M | 1280-1320 | 12.8-13.2 | ≥995 | ≥12.0 | ≥1114 | ≥14 | 318-342 | 40-43 | 100 ℃ |

| 45M | 1320-1370 | 13.2-13.7 | ≥995 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 | 100 ℃ |

| 48M | 1360-1420 | 13.6-14.2 | ≥1019 | ≥12.8 | ≥1114 | ≥14 | 366-390 | 46-49 | 100 ℃ |

| 50M | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1114 | ≥14 | 374-406 | 47-51 | 100 ℃ |

| 52M | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1035 | ≥13 | 390-422 | 49-53 | 100 ℃ |

| 33H | 1130-1170 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1353 | ≥17 | 247-271 | 31-34 | 120℃ |

| 35H | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 120℃ |

| 38H | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 | 120℃ |

| 40H | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | 120℃ |

| 42H | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 318-342 | 40-43 | 120℃ |

| 45H | 1320-1370 | 13.2-13.7 | ≥971 | ≥12.2 | ≥1353 | ≥17 | 342-366 | 43-46 | 120℃ |

| 48H | 1360-1420 | 13.6-14.2 | ≥1027 | ≥12.9 | ≥1353 | ≥17 | 366-390 | 46-49 | 120℃ |

| 50H | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 374-406 | 47-51 | 120℃ |

| 52H | 1420-1470 | 14.2-14.7 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 390-422 | 49-53 | 120℃ |

| 28SH | 1040-1090 | 10.4-10.9 | ≥780 | ≥9.8 | ≥1592 | ≥20 | 207-231 | 25-28 | 150 ℃ |

| 30SH | 1080-1130 | 11.3-11.7 | ≥804 | ≥10.1 | ≥1592 | ≥20 | 223-247 | 28-31 | 150 ℃ |

| 33SH | 1130-1170 | 11.3-11.7 | ≥844 | ≥10.6 | ≥1592 | ≥20 | 247-271 | 31-34 | 150 ℃ |

| 35SH | 1170-1220 | 11.7-12.2 | ≥876 | ≥11 | ≥1592 | ≥20 | 263-287 | 33-36 | 150 ℃ |

| 38SH | 1220-1250 | 12.2-12.5 | ≥907 | ≥10.5 | ≥1592 | ≥20 | 287-310 | 36-39 | 150 ℃ |

| 40SH | 1250-1280 | 12.5-12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 | 150 ℃ |

| 42SH | 1280-1320 | 12.8-13.2 | ≥971 | ≥12.2 | ≥1592 | ≥20 | 318-342 | 40-43 | 150 ℃ |

| 45SH | 1320-1370 | 13.2-13.7 | ≥979 | ≥12.3 | ≥1592 | ≥20 | 342-366 | 43-46 | 150 ℃ |

| 50SH | 1390-1440 | 13.9-14.4 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 374-406 | 47-51 | 150 ℃ |

| 52SH | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 390-422 | 49-53 | 150 ℃ |

| 28 UHH | 1020-1080 | 10.2-10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | 25-28 | 180 ℃ |

| 33UH | 1130-1170 | 11.3-11.7 | ≥812 | ≥10.2 | ≥1990 | ≥25 | 247-271 | 31-34 | 180 ℃ |

| 35UH | 1170-1220 | 11.7-12.2 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 263-287 | 33-36 | 180 ℃ |

| 38 uHH | 1220-1250 | 12.2-12.5 | ≥860 | ≥10.8 | ≥1990 | ≥25 | 287-310 | 36-39 | 180 ℃ |

| 40UH | 1250-1280 | 12.5-12.8 | ≥876 | ≥11.0 | ≥1990 | ≥25 | 302-326 | 38-41 | 180 ℃ |

| 42UH | 1270-1320 | 12.7-13.2 | ≥971 | ≥12.2 | ≥1990 | ≥25 | 310-342 | 39-43 | 180 ℃ |

| 50UH | 1390-1440 | 13.9-14.4 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 374-406 | 47-51 | 180 ℃ |

| 52UH | 1420-1470 | 14.2-14.7 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 390-422 | 49-53 | 180 ℃ |

| 28EH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | 25-28 | 200℃ |

| 30EH | 1080-1130 | 11.3-11.7 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-247 | 28-31 | 200℃ |

| 33EH | 1130-1170 | 11.3-11.7 | ≥820 | ≥10.3 | ≥2388 | ≥30 | 247-271 | 31-34 | 200℃ |

| 35EH | 1170-1220 | 11.7-12.2 | ≥836 | ≥10.5 | ≥2388 | ≥30 | 263-287 | 33-36 | 200℃ |

| 28AH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2706 | ≥34 | 207-231 | 25-28 | 230 ℃ |

| 30AH | 1070-1130 | 10.7-11.3 | ≥812 | ≥10.2 | ≥2706 | ≥34 | 215-247 | 27-31 | 230 ℃ |

| 33AH | 1110-1170 | 11.1-11.7 | ≥820 | ≥10.3 | ≥2706 | ≥34 | 239-271 | 30-34 | 230 ℃ |

Imininingwane yokupakisha