Iimagnethi zeNeodymium zesiko

Imagnethi ye-neodymium yesiko ngokweemfuno zenkampani yakho. Sithengisa onke amabanga emagnethi e-neodymium, iimilo ezilungiselelweyo, ubungakanani kunye nokwaleka

I-Neodymium Magnets Manufacturer, umzi-mveliso waseTshayina

HuizhouItekhnoloji yeFullzenCo., Ltd yingcaliumenzi wemagnethi we-neodymium, umenzi wemagnethi yesiko, umzi-mveliso, kunye nomthengisi eTshayina ukusukela ngo-2016. Sikhethekileyo kuvavanyo, uyilo, ubunjineli, ukuvelisa, ukuhlola, kunye nokudityaniswa kweemagnethi ze-neodymium zesiko. Ukwenza ngokwezifiso ukuhlangabezana neemfuno zenkampani yakho. Sinikezela ngeemveliso ezingaphandle kweshelufu kunye neenkonzo ezilungiselelweyo, uyilo oluqhelekileyo lweemagnethi ezisisigxina, iimagnethi ze-neodymium ezenziwe ngokwezifiso, ezenzelwe ishishini lakho.

Khetha iimagnethi zakho zeNeodymium

Ividiyo yemagnethi yeNeodymium

Intshayelelo yeemagnethi zeNeodymium

Imagnethi yeNeodymium, ekwabizwa ngokuba yiNdFeB umazibuthe, yiTetragonal crystal system crystal eyenziwe nguNd2Fe14B. Yimpahla yamagnetic eyenziwe kwi-metal praseodymium neodymium ngokulungiselela kunye ne-sintering. Olu hlobo umazibuthe umazibuthe osisigxina ogama umazibuthe ngowesibini kuphela kwi-Absolute zero holmium umazibuthe, kwaye ikwayeyona isetyenziswa ngokuqhelekileyo umazibuthe oRare-earth.

I-Neodymium yemagnethi yokwakheka kweekhemikhali

I-Neodymium iron boron esisigxina yemagnethi imathiriyeli yemagnethi esisigxina esekwe kwikhompawundi ye-intermetallic Nd2Fe14B. Amalungu aphambili ngamacandelo omhlaba anqabileyo i-neodymium (Nd), intsimbi (Fe), kunye ne-boron (B). Eyona elementi inqabileyo yomhlaba yi-neodymium (Nd), enokutshintshwa ngokuyinxenye zezinye iintsimbi ezinqabileyo zomhlaba ezifana ne-dysprosium (Dy) kunye ne-praseodymium (Pr) ukufumana iipropati ezahlukeneyo. Intsimbi inokutshintshwa ngokuyinxenye zezinye iintsimbi ezifana ne-cobalt (Co) kunye ne-aluminiyam (Al). Umxholo we-boron uncinci, kodwa udlala indima ebalulekileyo ekwenziweni kwe-tetragonal crystal structure intermetallic compounds, okwenza iikhompawundi zibe ne-saturation yamagnetization ephezulu, i-uniaxial anisotropy ephezulu, kunye nobushushu obuphezulu beCurie.

Imagnethi yeNeodymium Inkqubo yokuhamba

Inkqubo yokuhamba:ukuhlanganisa → ukunyibilika nokwenza ingot/ukujula ngemicu → ukwenza umgubo → ukubumba → ukuthambisa nokufutha → uvavanyo lwemagnethi → ukusetyenzwa kokusila → ukusetyenzwa kwephini lokusika → ukwenza i-electroplating → imveliso egqityiweyo. Izithako zisisiseko, kwaye i-sintering kunye nokuthambisa ngundoqo.

Izixhobo zokuvelisa kunye nezixhobo zokuvavanya ukusebenza kwe-neodymium iron boron blank blanks:Kubandakanya isithando somlilo esinyibilikayo, isithando somlilo esinyibilikayo, umatshini wokutyumza, umatshini wokuhamba komoya, umatshini wokubumba umatshini, umatshini wokupakisha we-vacuum, umatshini wokushicilela we-isostatic, isithando somlilo, isithando somlilo sokucoca ubushushu, umvavanyi wokusebenza kwemagnethi, imitha yeGaussian.

I-Neodymium iron boron magnet machining izixhobo:ukugaya okungenaziko, umatshini ojikelezayo, ukugaya isiphelo esiphindwe kabini, ukugaya isicaba, umatshini wokusika, ukugaya ngamacala amabini, ukusika ucingo, i-bench drill, ukugaya ngokungaqhelekanga, njl.

izicelo zemagnethi zeNeodymium

I-Sintered neodymium iron boron isigxina semagnethi izixhobo zineempawu ezibalaseleyo zemagnethi kwaye zisetyenziswa ngokubanzi kwiinkalo ezifana ne-electronics, oomatshini bamandla, izixhobo zonyango, iithoyi, ukupakishwa, oomatshini be-hardware, i-aerospace, njl.

Neodymium umazibuthe isalathiso uzibuthe kunyeumgangatho wokwaleka

Awukwazanga ukufumana into oyifunayo?

Ngokubanzi, kukho izitokhwe zeemagnethi eziqhelekileyo ze-neodymium okanye izinto ezikrwada kwindawo yethu yokugcina. Kodwa ukuba unemfuno ekhethekileyo, sikwabonelela ngenkonzo yokwenza ngokwezifiso. Siyayamkela iOEM/ODM.

Iimagnethi zeNeodymium zesiko

HuizhouItekhnoloji yeFullzenI-Co., Ltd ngumenzi wemagnethi oqeqeshiweyo. Inkampani yethu yenza isiko lemagnethi yomhlaba enqabileyo kwaye yenye yabenzi bemagnethi abaphezulu besiko. Sikhethekileyo kuvavanyo, uyilo, ubunjineli, ukuvelisa, ukuhlola kunye nokudibanisa.iimagnethi ze-neodymium zesiko. Ukwenza ngokwezifiso ukuhlangabezana neemfuno zenkampani yakho.Njengoko isikhokelo sesiko silandelayo sibonisa, sithengisa imagnethi ye-neodymium epheleleyo. Sinikezela ngeemveliso ezingaphandle kweshelufu kunye neenkonzo ezilungiselelwe wena, umazibuthe osisigxina, ezenzelwe ishishini lakho. Njengomazibuthe omkhulu we-neodymium arc ezenzelwe wena.

Ubungakanani kunye nokumila:

Singabonelela nge-customizedidiski, isilinda, umsesane, ityhubhu yesikwere, ibhloko yoxande, i-arc, i-countersunk, ihuku kunye nezinye iimagnethi ezisisigxina ezingaqhelekanga.

Ukwenziwa:

Sisebenzisa i-automationizixhoboukusika kunye nokugaya izinto eziluhlaza ukwenza imilinganiselo yemagnethi esisigxina oyifunayo, kunye nokunyamezelana okuncinci, ukufezekisa umphumo wokugqiba.

Unyango lomphezulu:

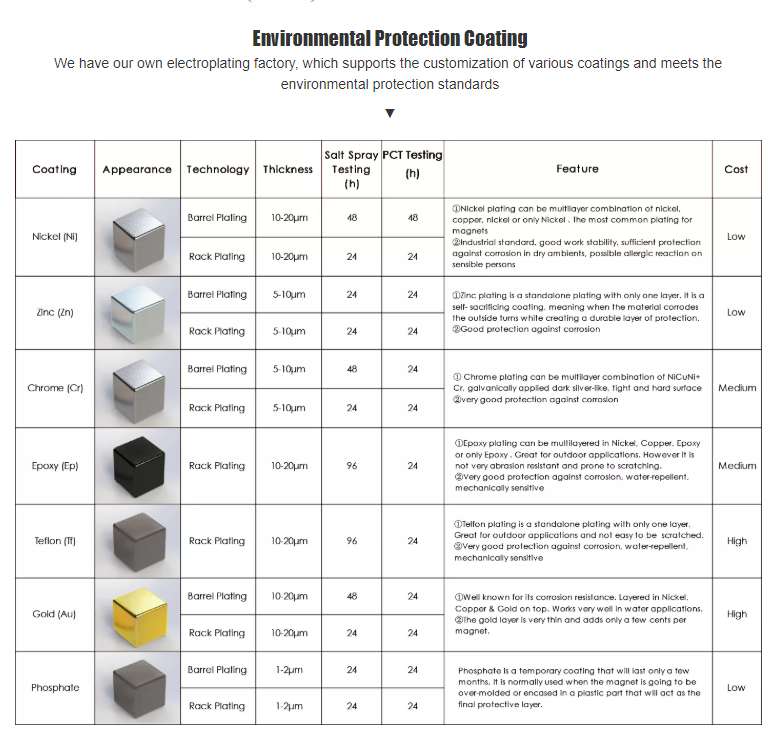

Iimagnethi ezisisigxina kulula ukuba zifakwe kwi-oxidized. Ngokweemfuno zabathengi, umphezulu uya kufakwa, i-epoxy coated okanye i-electroplated ukukhusela ukubola. Sinokubonelela nge-nickel plating, i-galvanization, i-electrophoresis kunye nezinye iinkonzo.

Amanqaku obushushu:

Umazibuthe osisigxina bubushushu bobushushu. Siya kuvelisa ngokungqongqo ngokwemfuno yomthengi yeemagnethi ezisisigxina ezinokumelana nobushushu obuphezulu.

Isikhokelo esiqhelekileyo

| Izinto eziphathekayo | I-Sintered Neodymium-Iron-Boron ( NdFeB ) | |

| Ubungakanani | Isiko | |

| Ubume | Btshixa,Disc,Cisilinda,Bar,Ring, Cngaphandle, IcandeloHkulungile,Cphezulu,Ti-rapezoid,Iiimilo eziqhelekileyo, njl. | |

| Ukusebenza | N33 N35 N38 N40 N42 N45 N48 N50 N52N54 njl. | |

| Ukwaleka | Zn, Ni-Cu-Ni, Ni, Gold, Silver, Copper, Epoxy, Chrome, njl | |

| Ukunyamezela ubungakanani | ±0.05mm yobukhulu/ubude, ±0.1mm yobubanzi/ubude | |

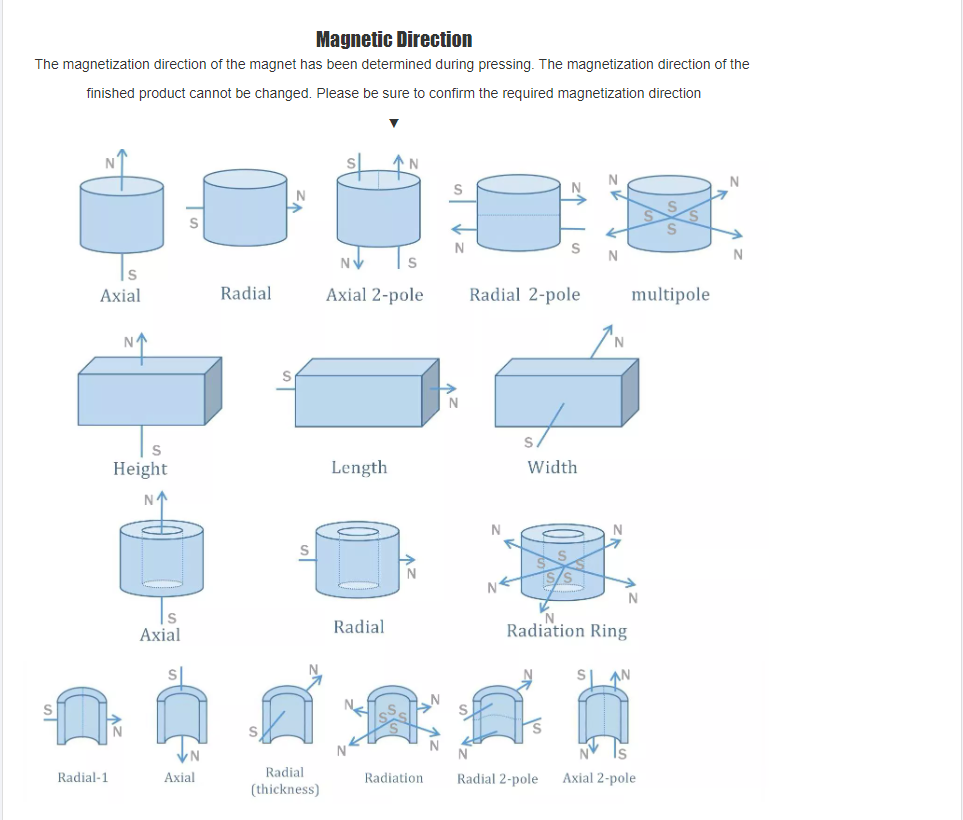

| Imagnethi | Ubutyebe bunemagnethi, iAxially Magnetized, Diametrally Magnetized, iipali ezininzi ezenziwe ngemagnethi, iRadial Magnetized. (Iimfuno ezikhethekileyo ezenziwe ngemagnethi) | |

| Max. Ubushushu bokusebenza | IBanga | Max. Ubushushu bokusebenza |

| N35-N52 | 80°C (176°F) | |

| 33M- 48M | 100°C (212°F) | |

| 33H-48H | 120°C (248°F) | |

| 30SH-45SH | 150°C (302°F) | |

| 30UH-40UH | 180°C (356°F) | |

| 28EH-38EH | 200°C (392°F) | |

| 28AH-35AH | 220°C (428°F) | |

MOQ kunye nexesha lokukhokela

| Amaqhekeza | Ixesha lokukhokhela |

| 1000-10000 | Iintsuku ezili-10 |

| 10000-100000 | Iintsuku ezingama-20 |

| 100000-1000000 | Iintsuku ezingama-30 |

Yintoni esinokukunika yona...

Singabavelisi beMagnet yeNeodymium kunye nomthengisi eTshayina. Sinokuvelisa i-Neodymium Magnet (imagnethi yeNdFeB) ngokweemfuno zakho.

Ukusebenza kwemagnethi

Kukho ubukhulu becala ezi parameters zintathu zilandelayo ukumisela ukusebenza umazibuthe:

I-Remanence Br: Emva kokuba i-magnet esisigxina ifakwe kwi-saturation yobuchwephesha kwaye intsimi ye-magnetic yangaphandle isusiwe, i-Br egciniweyo ibizwa ngokuba yi-residual magnetic induction.

Amandla okunyanzela i-Hc: Ukunciphisa i-B yemagnethi esisigxina enziwe umazibuthe ukuya kwi-saturation yobugcisa ukuya ku-zero, umva ofunekayo wemagnethi yamandla ibizwa ngokuba yi-magnetic induction force force, efinyeziweyo njengamandla okunyanzela.

Imveliso yamandla emagnethi BH: Imele uxinaniso lwamandla kazibuthe osekwe yimagnethi kwindawo yesikhewu somoya (isithuba esiphakathi kweepali zemagnethi ezimbini zemagnethi), oko kukuthi, amandla amileyo wemagnetostatic ngokweyunithi yomthamo womsantsa womoya. Ekubeni la mandla alingana nemveliso ye-magnetic Bm kunye ne-Hm, ibizwa ngokuba yimveliso yamandla omagnetic.

Sinokwenza iimagnethi ezisisigxina kunye neepropati phakathiN35-N54kwimarike.

IParameter yeMaginethi

| IBanga | Remanence | Ukunyanzeliswa kwamandla | Amandla okunyanzeliswa angaphakathi | Ubuninzi beMveliso yaMandla | ITemp yokuSebenza | ||||

| Br | Hcb | Hcj | BH ubukhulu | Tw | |||||

| mT | KGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | ||

| N35 | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 80℃ |

| N38 | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | 80℃ |

| N40 | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥955 | ≥12 | 302-326 | 38-41 | 80℃ |

| N42 | 1280-1320 | 12.8-13.2 | ≥923 | ≥11.6 | ≥955 | ≥12 | 318-342 | 40-43 | 80℃ |

| N45 | 1320-1370 | 13.2-13.7 | ≥876 | ≥11.0 | ≥955 | ≥12 | 342-366 | 43-46 | 80℃ |

| N48 | 1370-1420 | 13.7-14.2 | ≥892 | ≥11.2 | ≥955 | ≥12 | 366-390 | 46-49 | 80℃ |

| N50 | 1390-1440 | 13.9-14.4 | ≥836 | ≥10.5 | ≥955 | ≥12 | 374-406 | 47-51 | 80℃ |

| N52 | 1420-1470 | 14.2-14.7 | ≥836 | ≥10.5 | ≥876 | ≥11 | 390-422 | 49-53 | 80℃ |

| N55 | 1460-1520 | 14.6-15.2 | ≥716 | ≥9 | ≥876 | ≥11 | 414-446 | 52-56 | 80℃ |

| 35M | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 100℃ |

| 38M | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | 100℃ |

| 40M | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | 100℃ |

| 42M | 1280-1320 | 12.8-13.2 | ≥995 | ≥12.0 | ≥1114 | ≥14 | 318-342 | 40-43 | 100℃ |

| 45M | 1320-1370 | 13.2-13.7 | ≥995 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 | 100℃ |

| 48M | 1360-1420 | 13.6-14.2 | ≥1019 | ≥12.8 | ≥1114 | ≥14 | 366-390 | 46-49 | 100℃ |

| 50M | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1114 | ≥14 | 374-406 | 47-51 | 100℃ |

| 52M | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1035 | ≥13 | 390-422 | 49-53 | 100℃ |

| 33H | 1130-1170 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1353 | ≥17 | 247-271 | 31-34 | 120℃ |

| 35H | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 120℃ |

| 38H | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 | 120℃ |

| 40H | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | 120℃ |

| 42H | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 318-342 | 40-43 | 120℃ |

| 45H | 1320-1370 | 13.2-13.7 | ≥971 | ≥12.2 | ≥1353 | ≥17 | 342-366 | 43-46 | 120℃ |

| 48H | 1360-1420 | 13.6-14.2 | ≥1027 | ≥12.9 | ≥1353 | ≥17 | 366-390 | 46-49 | 120℃ |

| 50H | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 374-406 | 47-51 | 120℃ |

| 52H | 1420-1470 | 14.2-14.7 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 390-422 | 49-53 | 120℃ |

| 28SH | 1040-1090 | 10.4-10.9 | ≥780 | ≥9.8 | ≥1592 | ≥20 | 207-231 | 25-28 | 150℃ |

| 30SH | 1080-1130 | 11.3-11.7 | ≥804 | ≥10.1 | ≥1592 | ≥20 | 223-247 | 28-31 | 150℃ |

| 33SH | 1130-1170 | 11.3-11.7 | ≥844 | ≥10.6 | ≥1592 | ≥20 | 247-271 | 31-34 | 150℃ |

| 35SH | 1170-1220 | 11.7-12.2 | ≥876 | ≥11 | ≥1592 | ≥20 | 263-287 | 33-36 | 150℃ |

| 38SH | 1220-1250 | 12.2-12.5 | ≥907 | ≥10.5 | ≥1592 | ≥20 | 287-310 | 36-39 | 150℃ |

| 40SH | 1250-1280 | 12.5-12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 | 150℃ |

| 42SH | 1280-1320 | 12.8-13.2 | ≥971 | ≥12.2 | ≥1592 | ≥20 | 318-342 | 40-43 | 150℃ |

| 45SH | 1320-1370 | 13.2-13.7 | ≥979 | ≥12.3 | ≥1592 | ≥20 | 342-366 | 43-46 | 150℃ |

| 50SH | 1390-1440 | 13.9-14.4 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 374-406 | 47-51 | 150℃ |

| 52SH | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 390-422 | 49-53 | 150℃ |

| 28UH | 1020-1080 | 10.2-10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | 25-28 | 180℃ |

| 33UH | 1130-1170 | 11.3-11.7 | ≥812 | ≥10.2 | ≥1990 | ≥25 | 247-271 | 31-34 | 180℃ |

| 35UH | 1170-1220 | 11.7-12.2 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 263-287 | 33-36 | 180℃ |

| 38UH | 1220-1250 | 12.2-12.5 | ≥860 | ≥10.8 | ≥1990 | ≥25 | 287-310 | 36-39 | 180℃ |

| 40UH | 1250-1280 | 12.5-12.8 | ≥876 | ≥11.0 | ≥1990 | ≥25 | 302-326 | 38-41 | 180℃ |

| 42UH | 1270-1320 | 12.7-13.2 | ≥971 | ≥12.2 | ≥1990 | ≥25 | 310-342 | 39-43 | 180℃ |

| 50UH | 1390-1440 | 13.9-14.4 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 374-406 | 47-51 | 180℃ |

| 52UH | 1420-1470 | 14.2-14.7 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 390-422 | 49-53 | 180℃ |

| 28EH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | 25-28 | 200℃ |

| 30EH | 1080-1130 | 11.3-11.7 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-247 | 28-31 | 200℃ |

| 33EH | 1130-1170 | 11.3-11.7 | ≥820 | ≥10.3 | ≥2388 | ≥30 | 247-271 | 31-34 | 200℃ |

| 35EH | 1170-1220 | 11.7-12.2 | ≥836 | ≥10.5 | ≥2388 | ≥30 | 263-287 | 33-36 | 200℃ |

| 28AH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2706 | ≥34 | 207-231 | 25-28 | 230℃ |

| 30AH | 1070-1130 | 10.7-11.3 | ≥812 | ≥10.2 | ≥2706 | ≥34 | 215-247 | 27-31 | 230℃ |

| 33AH | 1110-1170 | 11.1-11.7 | ≥820 | ≥10.3 | ≥2706 | ≥34 | 239-271 | 30-34 | 230℃ |

Iinkcukacha zokupakisha