Limanete tsa Neodymium tse Tloaelehileng

Limanete tsa neodymium tsa tloaelo ho latela litlhoko tsa k'hamphani ea hau. Re rekisa limaraka tsohle tsa makenete a neodymium, libopeho tse tloahelehileng, boholo le lintja

Moetsi oa Magnets oa Neodymium, fektheri ea Chaena

HuizhouTheknoloji ea FullzenCo., Ltd ke setsebimoetsi oa makenete oa neodymium, moetsi oa makenete oa tloaelo, fektheri, le mofani oa thepa Chaena ho tloha ka 2016. Re ikhethile ka liteko, moralo, boenjiniere, tlhahiso, tlhahlobo, le ho kopanya mabone a tloaelo a neodymium. Boikemisetso ho fihlela litlhoko tsa k'hamphani ea hau. Re fana ka lihlahisoa tse kantle ho sethala hammoho le lits'ebeletso tse ikhethileng, moralo o iketselitsoeng oa limakete tse sa feleng, makenete a sebopeho sa neodymium, a etselitsoeng indasteri ea hau.

Khetha Limanete tsa hau tsa Neodymium

Neodymium magnet video

Kenyelletso ea makenete a Neodymium

Neodymium magnet, e tsejoang hape e le NdFeB makenete, ke kristale ea kristale ea Tetragonal e entsoeng ke Nd2Fe14B. Ke thepa ea makenete e entsoeng ka tšepe ea praseodymium neodymium ka ho itokisa le ho siling. Mofuta ona oa makenete ke makenete oa ka ho sa feleng oo makenete e leng oa bobeli ho Absolute zero holmium makenete, hape ke makenete a sebelisoang ka ho fetesisa a Rare-earth.

Neodymium magnets sebopeho sa lik'hemik'hale

Neodymium iron boron permanent magnet material ke sesebelisoa sa makenete se sa feleng se thehiloeng ho motsoako oa intermetallic Nd2Fe14B. Likarolo tse kholo ke likarolo tse sa tloaelehang tsa lefatše neodymium (Nd), tšepe (Fe), le boron (B). Karolo e ka sehloohong ea lefatše e sa tloaelehang ke neodymium (Nd), e ka nkeloang sebaka ke lirafshoa tse ling tse sa tloaelehang tse kang dysprosium (Dy) le praseodymium (Pr) ho fumana thepa e fapaneng. Iron e ka boela ea nkeloa sebaka ke litšepe tse ling tse kang cobalt (Co) le aluminium (Al). Likahare tsa boron li nyane, empa li bapala karolo ea bohlokoa ho thehoeng ha metsoako ea kristale ea tetragonal intermetallic, ho etsa hore metsoako e be le matla a phahameng a saturation, anisotropy e phahameng ea uniaxial, le mocheso o phahameng oa Curie.

Limakenete tsa Neodymium Phallo ea ts'ebetso

Phallo ea ts'ebetso:ho betha → ho qhibiliha le ho etsa li-ingot/ho hlobola Metsoako ke motheo, 'me sintering le tempering ke senotlolo.

Lisebelisoa tsa tlhahiso le lisebelisoa tsa tlhahlobo ea ts'ebetso bakeng sa likheo tsa neodymium iron boron magnet:ho kenyelletsa le sebopi se qhibilihang, sebopi se lahlang, mochini o silakanyang, leloala la moea, mochini o kopanyang, mochini o pakang sekontiri, mochini oa khatiso oa isostatic, sebōpi sa sintering, sebopi sa mocheso oa mocheso, tlhahlobo ea ts'ebetso ea makenete, mitha ea Gaussian.

Neodymium iron boron magnet machining lisebelisoa:ho sila ho se nang setsi, mochine o pota-potileng, ho sila ka makhetlo a mabeli, ho sila ka mokhoa o bataletseng, mochine oa ho senya, ho sila ka mahlakoreng a mabeli, ho khaola terata, ho cheka benche, ho sila ka tsela e sa tloaelehang, joalo-joalo.

Lisebelisoa tsa magnets tsa Neodymium

Sintered neodymium iron boron permanent magnets e na le thepa e babatsehang ea makenete 'me e sebelisoa haholo libakeng tse kang lisebelisoa tsa elektroniki, mechine ea matla, lisebelisoa tsa bongaka, lipapali, liphutheloana, mechine ea hardware, sefofane, joalo-joalo. Tse tloaelehileng li kenyelletsa li-motors tsa magnete tse sa feleng, libui, li-separators tsa magnetic, li-disk tsa k'homphieutha, lisebelisoa tsa litšoantšo tsa magnetic resonance, joalo-joalo.

Tsela ea ho etsa makenete ea Neodymium leho roala bokahodimo

Ha u fumane seo u se batlang?

Ka kakaretso, ho na le li-stock tsa limatlase tse tloaelehileng tsa neodymium kapa lisebelisoa tse tala ka ntlong ea rona ea polokelo. Empa haeba u na le tlhokahalo e khethehileng, re boetse re fana ka tšebeletso ea ho iketsetsa motho ka mong. Re boetse re amohela OEM/ODM.

Limanete tsa Neodymium tse Tloaelehileng

HuizhouTheknoloji ea FullzenCo., Ltd ke setsebi sa moetsi oa makenete. K'hamphani ea rona e itloaetsa limakete tsa lefatše tse sa tloaelehang ebile e le e 'ngoe ea bahlahisi ba hloahloa ba makenete.limakenete tsa neodymium tse ikhethileng. Ho itloaetsa ho fihlela litlhoko tsa k'hamphani ea hau. Joalo ka ha tataiso e latelang e bontša, re rekisa limatlase tse felletseng tsa neodymium. Re fana ka lihlahisoa tse kantle ho sethala hammoho le lits'ebeletso tse ikhethileng, makenete ea kamehla, e etselitsoeng indasteri ea hau joalo ka mabone a maholo a neodymium arc a etselitsoeng uena.

Boholo le sebopeho:

Re ka fana ka customizeddisc, moqomo, selikalikoe, sekwere cube, khutlonnetsepa block, arc, countersunk, hook le tse ling tse sa tloaelehang magnets sa feleng.

Moetso:

Re sebelisa boiketsetsolisebelisoaho seha le ho sila lisebelisoa tse tala ho etsa litekanyo tsa makenete e sa feleng eo u e batlang, ka mamello e nyane, ho fihlela phello ea ho qetela.

Phekolo ea sefahleho:

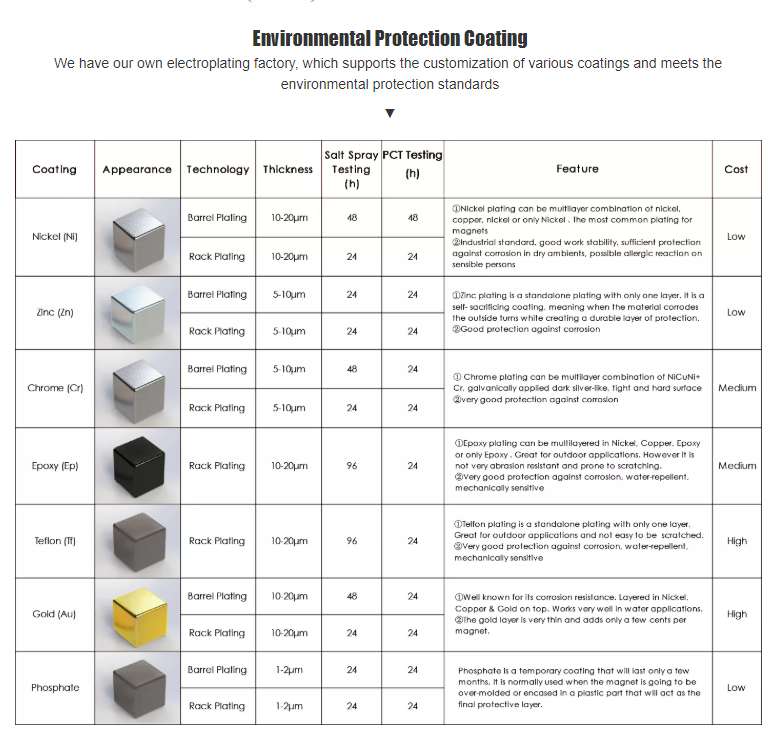

Limanete tse sa feleng li bonolo ho oxidized. Ho ea ka litlhoko tsa bareki, bokaholimo bo tla koaheloa, bo koahetsoe ka epoxy kapa electroplated ho thibela kutu. Re ka fana ka nickel plating, galvanization, electrophoresis le litšebeletso tse ling.

Lintlha tsa Mocheso:

Magnetic e sa feleng ha e na mocheso. Re tla hlahisa ka tieo ho latela tlhoko ea moreki ea limakete tse sa feleng tse nang le khanyetso e phahameng ea mocheso.

Tataiso ea tloaelo

| Lintho tse bonahalang | Sintered Neodymium-Iron-Boron ( NdFeB ) | |

| Boholo | Tloaelo | |

| Sebopeho | Bnotlela,Disc,Csilindara,Bar,Rng, Countersunk, KaroloHhantle,Cholimo,Trapezoid, kelibopeho tse tloaelehileng, joalo-joalo. | |

| Tshebetso | N33 N35 N38 N40 N42 N45 N48 N50 N52N54 joalo-joalo. | |

| Ho roala | Zn, Ni-Cu-Ni, Ni, Khauta, Silevera, Koporo, Epoxy, Chrome, joalo-joalo | |

| Mamello ea boholo | ± 0.05mm bakeng sa diamater / botenya, ± 0.1mm bakeng sa bophara / bolelele | |

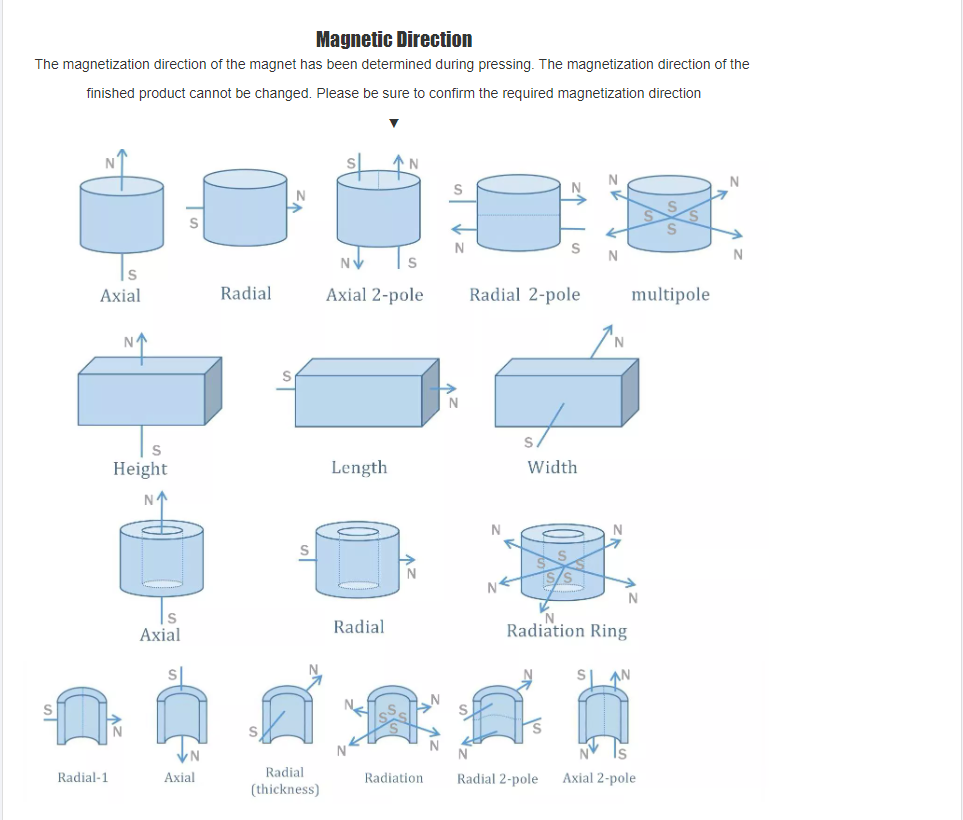

| Magnetization | Botenya bo na le Magnetized, Axially Magnetized, Diametrally Magnetized, Multi-poles magnetized, Radial Magnetized. (Litlhoko tse ikhethileng tse entsoeng ke makenete) | |

| Max. Mocheso oa Mosebetsi | Kereiti | Max. Mocheso oa ho sebetsa |

| N35-N52 | 80°C (176°F) | |

| 33M-48M | 100°C (212°F) | |

| 33H-48H | 120°C (248°F) | |

| 30SH-45SH | 150°C (302°F) | |

| 30UH-40UH | 180°C (356°F) | |

| 28EH-38EH | 200°C (392°F) | |

| 28AH-35AH | 220°C (428°F) | |

MOQ & Nako ea Pele

| Likotoana | Lead time |

| 1000-10000 | 10 matsatsi |

| 10000-100000 | Matsatsi a 20 |

| 100000-1000000 | Matsatsi a 30 |

Seo re ka u fang sona…

Re litsebi tsa Neodymium Magnet moetsi le mofani oa thepa Chaena. Re ka hlahisa Neodymium Magnet (NdFeB makenete) ho latela litlhoko tsa hau.

Tshebetso ea makenete

Haholo-holo ho na le likarolo tse tharo tse latelang tsa ts'ebetso ho tseba hore na magnet o sebetsa joang:

Remanence Br: Kamora hore makenete e sa feleng e hoketsoe ho saturation ea tekheniki mme matla a khoheli a kantle a tlosoe, Br e bolokiloeng e bitsoa induction e setseng ea makenete.

Coercive Force Hc: Ho fokotsa B ea makenete ea ka ho sa feleng e hohetsoeng ka botekgeniki ho fihla ho zero, matla a reverse a matla a khoheli a bitsoa matla a khoheli a khoheli, a khutsufalitsoeng joalo ka matla a qobellang.

Sehlahisoa sa Magnetic energy BH: E emela matla a khoheli a matla a khoheli a thehiloeng ke makenete sebakeng sa lekhalo la moea (sebaka se pakeng tsa lipalo tse peli tsa makenete tsa makenete), ke hore, matla a static magnetostatic ho bophahamo ba yuniti ea lekhalo la moea. Kaha matla ana a lekana le sehlahisoa sa Bm le Hm ea makenete, e bitsoa sehlahisoa sa matla a khoheli.

Re ka Customize magnets ka ho sa feleng le thepa pakeng tsaN35-N54'marakeng.

Parameter ea Magnets

| Kereiti | Remanence | Matla a Qobellang | Matla a Koetliso a ka hare | Maximum Energy Product | Mocheso o sebetsang | ||||

| Br | Hcb | Hcj | BH max | Tw | |||||

| mT | KGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGO | ||

| N35 | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 80 ℃ |

| N38 | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | 80 ℃ |

| N40 | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥955 | ≥12 | 302-326 | 38-41 | 80 ℃ |

| N42 | 1280-1320 | 12.8-13.2 | ≥923 | ≥11.6 | ≥955 | ≥12 | 318-342 | 40-43 | 80 ℃ |

| N45 | 1320-1370 | 13.2-13.7 | ≥876 | ≥11.0 | ≥955 | ≥12 | 342-366 | 43-46 | 80 ℃ |

| N48 | 1370-1420 | 13.7-14.2 | ≥892 | ≥11.2 | ≥955 | ≥12 | 366-390 | 46-49 | 80 ℃ |

| N50 | 1390-1440 | 13.9-14.4 | ≥836 | ≥10.5 | ≥955 | ≥12 | 374-406 | 47-51 | 80 ℃ |

| N52 | 1420-1470 | 14.2-14.7 | ≥836 | ≥10.5 | ≥876 | ≥11 | 390-422 | 49-53 | 80 ℃ |

| N55 | 1460-1520 | 14.6-15.2 | ≥716 | ≥9 | ≥876 | ≥11 | 414-446 | 52-56 | 80 ℃ |

| 35M | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 100 ℃ |

| 38M | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | 100 ℃ |

| 40M | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | 100 ℃ |

| 42M | 1280-1320 | 12.8-13.2 | ≥995 | ≥12.0 | ≥1114 | ≥14 | 318-342 | 40-43 | 100 ℃ |

| 45M | 1320-1370 | 13.2-13.7 | ≥995 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 | 100 ℃ |

| 48M | 1360-1420 | 13.6-14.2 | ≥1019 | ≥12.8 | ≥1114 | ≥14 | 366-390 | 46-49 | 100 ℃ |

| 50M | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1114 | ≥14 | 374-406 | 47-51 | 100 ℃ |

| 52M | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1035 | ≥13 | 390-422 | 49-53 | 100 ℃ |

| 33H | 1130-1170 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1353 | ≥17 | 247-271 | 31-34 | 120 ℃ |

| 35H | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 120 ℃ |

| 38H | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 | 120 ℃ |

| 40H | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | 120 ℃ |

| 42H | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 318-342 | 40-43 | 120 ℃ |

| 45H | 1320-1370 | 13.2-13.7 | ≥971 | ≥12.2 | ≥1353 | ≥17 | 342-366 | 43-46 | 120 ℃ |

| 48H | 1360-1420 | 13.6-14.2 | ≥1027 | ≥12.9 | ≥1353 | ≥17 | 366-390 | 46-49 | 120 ℃ |

| 50H | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 374-406 | 47-51 | 120 ℃ |

| 52H | 1420-1470 | 14.2-14.7 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 390-422 | 49-53 | 120 ℃ |

| 28SH | 1040-1090 | 10.4-10.9 | ≥780 | ≥9.8 | ≥1592 | ≥20 | 207-231 | 25-28 | 150 ℃ |

| 30SH | 1080-1130 | 11.3-11.7 | ≥804 | ≥10.1 | ≥1592 | ≥20 | 223-247 | 28-31 | 150 ℃ |

| 33SH | 1130-1170 | 11.3-11.7 | ≥844 | ≥10.6 | ≥1592 | ≥20 | 247-271 | 31-34 | 150 ℃ |

| 35SH | 1170-1220 | 11.7-12.2 | ≥876 | ≥11 | ≥1592 | ≥20 | 263-287 | 33-36 | 150 ℃ |

| 38SH | 1220-1250 | 12.2-12.5 | ≥907 | ≥10.5 | ≥1592 | ≥20 | 287-310 | 36-39 | 150 ℃ |

| 40SH | 1250-1280 | 12.5-12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 | 150 ℃ |

| 42SH | 1280-1320 | 12.8-13.2 | ≥971 | ≥12.2 | ≥1592 | ≥20 | 318-342 | 40-43 | 150 ℃ |

| 45SH | 1320-1370 | 13.2-13.7 | ≥979 | ≥12.3 | ≥1592 | ≥20 | 342-366 | 43-46 | 150 ℃ |

| 50SH | 1390-1440 | 13.9-14.4 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 374-406 | 47-51 | 150 ℃ |

| 52SH | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 390-422 | 49-53 | 150 ℃ |

| 28UH | 1020-1080 | 10.2-10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | 25-28 | 180 ℃ |

| 33 UH | 1130-1170 | 11.3-11.7 | ≥812 | ≥10.2 | ≥1990 | ≥25 | 247-271 | 31-34 | 180 ℃ |

| 35 UH | 1170-1220 | 11.7-12.2 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 263-287 | 33-36 | 180 ℃ |

| 38UH | 1220-1250 | 12.2-12.5 | ≥860 | ≥10.8 | ≥1990 | ≥25 | 287-310 | 36-39 | 180 ℃ |

| 40UH | 1250-1280 | 12.5-12.8 | ≥876 | ≥11.0 | ≥1990 | ≥25 | 302-326 | 38-41 | 180 ℃ |

| 42 UH | 1270-1320 | 12.7-13.2 | ≥971 | ≥12.2 | ≥1990 | ≥25 | 310-342 | 39-43 | 180 ℃ |

| 50UH | 1390-1440 | 13.9-14.4 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 374-406 | 47-51 | 180 ℃ |

| 52 UH | 1420-1470 | 14.2-14.7 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 390-422 | 49-53 | 180 ℃ |

| 28EH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | 25-28 | 200 ℃ |

| 30EH | 1080-1130 | 11.3-11.7 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-247 | 28-31 | 200 ℃ |

| 33EH | 1130-1170 | 11.3-11.7 | ≥820 | ≥10.3 | ≥2388 | ≥30 | 247-271 | 31-34 | 200 ℃ |

| 35EH | 1170-1220 | 11.7-12.2 | ≥836 | ≥10.5 | ≥2388 | ≥30 | 263-287 | 33-36 | 200 ℃ |

| 28AH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2706 | ≥34 | 207-231 | 25-28 | 230 ℃ |

| 30AH | 1070-1130 | 10.7-11.3 | ≥812 | ≥10.2 | ≥2706 | ≥34 | 215-247 | 27-31 | 230 ℃ |

| 33AH | 1110-1170 | 11.1-11.7 | ≥820 | ≥10.3 | ≥2706 | ≥34 | 239-271 | 30-34 | 230 ℃ |

Lintlha tsa ho paka