Magnetrada Neodymium ee Gaarka ah

Magnets neodymium gaar ah si waafaqsan shuruudaha shirkaddaada. Waxaan iibinaa dhammaan darajooyinka magnet-ka neodymium, qaababka gaarka ah, cabbirka iyo dahaarka

Soo-saaraha Magnet-ka Neodymium, warshad ku taal Shiinaha

XuizhouFarsamada FullzenCo., Ltd waa xirfadlesoo saaraha magnet neodymium, soo saaraha magnet-ka gaarka ah, warshad, iyo alaab-qeybiye Shiinaha laga soo bilaabo 2016. Waxaan ku takhasusay tijaabinta, naqshadeynta, injineernimada, soo saarista, kormeerka, iyo isu-imaatinka magnet-ka neodymium ee gaarka ah. Habaynta si loo daboolo shuruudaha shirkaddaada. Waxaan bixinaa alaabada aan khaanadaha lahayn iyo sidoo kale adeegyo gaar ah, naqshad gaar ah oo birlabyo joogto ah, birlabyo neodymium qaabaysan, oo loogu talagalay warshadahaaga.

Dooro Neodymium Magnetskaaga

Fiidiyowga Neodymium magnetka

Neodymium magnets hordhac ah

Magnet-ka Neodymium, oo sidoo kale loo yaqaan magnet-ka NdFeB, waa kiristaalo nidaam kiristaalo ah oo Tetragonal ah oo uu sameeyay Nd2Fe14B. Waa walax bir ah oo laga sameeyay biraha praseodymium neodymium iyada oo loo marayo diyaarinta iyo sintering. Noocan birlabku waa birlab joogto ah oo birlabkiisu uu yahay kan labaad oo keliya Absolute zero holmium magnet, waana birlab-ka dhulka ee ugu badan ee la isticmaalo.

Neodymium magnets oo ka kooban kiimiko

Maaddada birta Neodymium boron joogto ah waa wax magnet joogto ah oo ku salaysan isku dhafka dhexdhexaadinta Nd2Fe14B. Qaybaha ugu muhiimsan waa curiyeyaasha dhulka naadirka ah neodymium (Nd), iron (Fe), iyo boron (B). Cunsurka ugu weyn ee dhifka ah waa neodymium (Nd), kaas oo qayb ahaan lagu bedeli karo biraha kale ee dhifka ah sida dysprosium (Dy) iyo praseodymium (Pr) si loo helo hanti kala duwan. Birta waxa kale oo qayb ahaan lagu bedeli karaa biraha kale sida cobalt (Co) iyo aluminium (Al). Maadada boronku waa mid yar, laakiin waxay door muhiim ah ka ciyaartaa samaynta qaab dhismeedka crystal tetragonal ee isku-dhafka ah, samaynta xeryahooda waxay leeyihiin magnetization saturation sare, anisotropy uniaxial sare, iyo heerkulka Curie sare.

Neodymium magnets socodka habka socodka

Habka socodka:Duubista → dhalaalidda iyo samaynta caleenta/tuurista → samaynta budada → samaynta → samaynta iyo xanaaqa → tijaabinta magnetic → farsamaynta shiidida → samaynta biin jarista → electroplating → alaabta dhammaatay. Maaddooyinka ayaa ah aasaaska, iyo kicinta iyo xanaaqa ayaa ah furaha.

Qalabka wax soo saarka iyo qalabka tijaabada waxqabadka ee meelaha bannaan ee bir-biyoodka boron ee neodymium:oo ay ku jiraan foornada dhalaalaysa, foornada tuurista xariijimaha, mashiinka burburinta, mishiinka hawo-mareenka, mashiinka wax lagu dhejiyo, mashiinka baakadaha faakuumka, mishiinka jaraa'id ee isostatic, foornada sintering, foornada faakuum daaweynta kulaylka, tijaabiyaha waxqabadka magnetic, Gaussian meter.

Qalabka mashiinnada birta Neodymium boron magnet:shiidid dhexda la'aan ah, mishiin wareeg ah, shiidi dhamaadka dhamaadka, shiidid siman, mishiinka goynta, laba-dhinac shiidi, goynta silig, laylinta kursiga, shiidi aan joogto ahayn, iwm.

Neodymium magnets codsiyada

Qalabka magnetka joogtada ah ee neodymium neodymium boron waxay leeyihiin sifooyin magnetic heer sare ah waxaana si ballaaran loo isticmaalaa meelaha sida elektiroonigga ah, mashiinnada awoodda, qalabka caafimaadka, alaabta lagu ciyaaro, baakadaha, mashiinnada hardware, hawada, iwm.

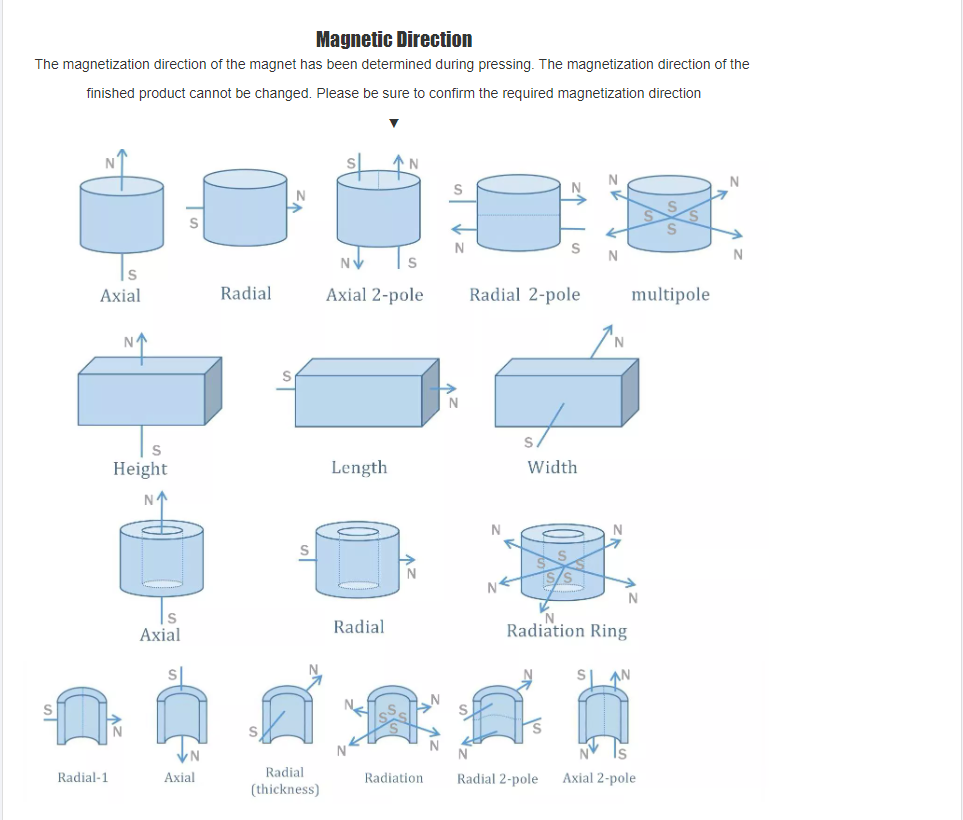

Neodymium magnets magnetization jihada iyodahaarka dusha sare

Miyaad kari wayday waxaad raadinayso?

Guud ahaan, waxa bakhaarkeena ku jira kaydyo magnets neodymium ah ama alaabta ceeriin ah. Laakiin haddii aad leedahay baahi gaar ah, waxaanu sidoo kale bixinaa adeeg habaynta. Waxaan sidoo kale aqbalnaa OEM/ODM.

Magnetrada Neodymium ee Gaarka ah

XuizhouFarsamada FullzenCompanymagnets neodymium caadada ah. Habaynta si loo buuxiyo shuruudaha shirkadda. Sida hagaha caadada ah ee soo socda uu muujinayo, waxaanu iibinaa magnets neodymium oo dhamaystiran. Waxaan bixinaa alaabo ka baxsan shelf-ka iyo sidoo kale adeegyo la habeeyey, magnet joogto ah oo caado ah, dawaar loogu sameeyay warshadahaaga. Sida magnets neodymium arc weyn oo adiga laguu habeeyey.

Cabbirka iyo qaabka:

Waxaan bixin karnaa habaysansaxanka, dhululubo, giraanta, cube square, block leydi, arc, countersunk, jillaab iyo magnets kale aan joogto ahayn joogto ah.

Soo-saarka:

Waxaan isticmaalnaa si toos ahqalabkasi aad u gooyso oo aad u shiiddo alaabta ceeriin si aad u sameyso cabbirrada magnetka joogtada ah ee aad rabto, oo leh dulqaad yar, si loo gaaro saameynta dhamaystirka.

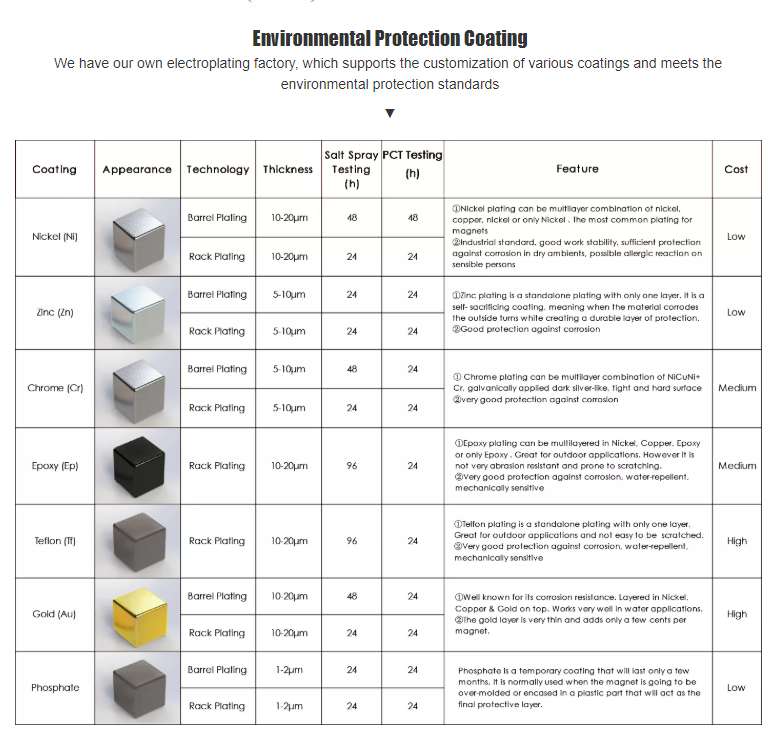

Daaweynta dusha sare:

Magnet-ka joogtada ahi waa ay fududahay in la oksidhiseeyo. Marka loo eego baahida macaamiisha, dusha sare waa la dahaadhay, dahaarka epoxy-ga ama korantada si looga hortago daxalka. Waxaan bixin karnaa daminta nikkel, galvanization, electrophoresis iyo adeegyo kale.

Qoraallada Heerkulka:

Magnet joogto ah ayaa xasaasi u ah heerkulka. Waxaan si adag u soo saari doonaa si waafaqsan baahida macaamiisha ee magnets joogto ah oo leh iska caabin heerkul sarreeya.

Hagaha gaarka ah

| Qalab | Neodymium-Iron-Boron Sintered (NdFeB) | |

| Cabbirka | Gaar ah | |

| Qaabka | Bquful,Dwaa,Cylinder,Bwaa,Ring, Coorsunk, QaybtaHwaayahay,Ckor,Traasoid, Iqaababka caadiga ah, iwm. | |

| Waxqabadka | N33 N35 N38 N40 N42 N45 N48 N50 N52N54 iwm. | |

| Dahaarka | Zn, Ni-Cu-Ni, Ni, Gold, Silver, Copper, Epoxy, Chrome, iwm | |

| dulqaadka cabbirka | ±0.05mm dhexroorka / dhumucda, ±0.1mm ballaca/dhererka | |

| Magnetization | Dhumucda Magnetized, Axially Magnetized, Dhexroor Magnetized, Tiirar badan magnetized, Radial Magnetized. (Shuruudaha gaarka ah ee la habeeyay magnetized) | |

| Max. Heerkulka shaqada | Darajo | Max. Heerkulka shaqada |

| N35-N52 | 80°C (176°F) | |

| 33M- 48M | 100°C (212°F) | |

| 33H-48H | 120°C (248°F) | |

| 30SH-45SH | 150°C (302°F) | |

| 30UH-40UH | 180°C (356°F) | |

| 28EH-38EH | 200°C (392°F) | |

| 28AH-35AH | 220°C (428°F) | |

MOQ & Waqtiga Hogaaminta

| Qaybo | Waqtiga Hogaaminta |

| 1000-10000 | 10 maalmood |

| 10000-100000 | 20 maalmood |

| 100000-100000 | 30 maalmood |

Waxa aanu ku siin karno…

Waxaan nahay xirfadle Neodymium Magnet soo saaraha iyo alaab-qeybiyaha gudaha Shiinaha. Waxaan soo saari karnaa Neodymium Magnet (NdFeB magnet) sida waafaqsan shuruudahaaga.

Waxqabadka birlabka

Inta badan waxaa jira saddex cabbir waxqabad oo soo socda si loo go'aamiyo waxqabadka magnetka:

Remanence Br: Ka dib markii magnet joogto ah lagu magnetized si ay u dheregto farsamada iyo goobta magnetic dibadda laga saaro, Br la hayo waxaa loo yaqaan induction magnetic.

Xoogga qasabka ah Hc: Si loo dhimo B ee birlabeedka joogtada ah ee magnetized laga dhigo dherjin farsamo ilaa eber, xoogga goobta magnetic roga ee loo baahan yahay waxaa loo yaqaannaa xoog qasabka magnetic, oo loo soo gaabiyo xoog qasab.

Alaabta tamarta magnetic BH: Waxay ka dhigan tahay cufnaanta tamarta magnetic ee uu aasaasay magnetka ee booska farqiga hawada (meel bannaan oo u dhaxaysa labada tiir ee magnetka), taas oo ah, tamarta magnetostatic ee halbeegga mugga hawada. Maadaama tamartani ay la mid tahay sheyga magnet-ka ee Bm iyo Hm, waxaa loo yaqaannaa alaabta tamarta magnetic.

Waxaan astaysto karaa magnet joogto ah oo leh hanti u dhexeeyaN35-N54suuqa.

Parameter of Magnets

| Darajo | Joogista | Xoog ku Qasab ah | Xoogaga qasabka ah ee gudaha | Wax soo saarka tamarta ugu badan | Heerkulka Shaqada | ||||

| Br | Hcb | Hcj | BH max | Tw | |||||

| mT | KGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | ||

| N35 | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 80℃ |

| N38 | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | 80℃ |

| N40 | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥955 | ≥12 | 302-326 | 38-41 | 80℃ |

| N42 | 1280-1320 | 12.8-13.2 | ≥923 | ≥11.6 | ≥955 | ≥12 | 318-342 | 40-43 | 80℃ |

| N45 | 1320-1370 | 13.2-13.7 | ≥876 | ≥11.0 | ≥955 | ≥12 | 342-366 | 43-46 | 80℃ |

| N48 | 1370-1420 | 13.7-14.2 | ≥892 | ≥11.2 | ≥955 | ≥12 | 366-390 | 46-49 | 80℃ |

| N50 | 1390-1440 | 13.9-14.4 | ≥836 | ≥10.5 | ≥955 | ≥12 | 374-406 | 47-51 | 80℃ |

| N52 | 1420-1470 | 14.2-14.7 | ≥836 | ≥10.5 | ≥876 | ≥11 | 390-422 | 49-53 | 80℃ |

| N55 | 1460-1520 | 14.6-15.2 | ≥716 | ≥9 | ≥876 | ≥11 | 414-446 | 52-56 | 80℃ |

| 35M | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 100 ℃ |

| 38M | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | 100 ℃ |

| 40M | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | 100 ℃ |

| 42M | 1280-1320 | 12.8-13.2 | ≥995 | ≥12.0 | ≥1114 | ≥14 | 318-342 | 40-43 | 100 ℃ |

| 45M | 1320-1370 | 13.2-13.7 | ≥995 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 | 100 ℃ |

| 48M | 1360-1420 | 13.6-14.2 | ≥1019 | ≥12.8 | ≥1114 | ≥14 | 366-390 | 46-49 | 100 ℃ |

| 50M | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1114 | ≥14 | 374-406 | 47-51 | 100 ℃ |

| 52M | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1035 | ≥13 | 390-422 | 49-53 | 100 ℃ |

| 33H | 1130-1170 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1353 | ≥17 | 247-271 | 31-34 | 120℃ |

| 35H | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 120℃ |

| 38H | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 | 120℃ |

| 40H | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | 120℃ |

| 42H | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 318-342 | 40-43 | 120℃ |

| 45H | 1320-1370 | 13.2-13.7 | ≥971 | ≥12.2 | ≥1353 | ≥17 | 342-366 | 43-46 | 120℃ |

| 48H | 1360-1420 | 13.6-14.2 | ≥1027 | ≥12.9 | ≥1353 | ≥17 | 366-390 | 46-49 | 120℃ |

| 50H | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 374-406 | 47-51 | 120℃ |

| 52H | 1420-1470 | 14.2-14.7 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 390-422 | 49-53 | 120℃ |

| 28SH | 1040-1090 | 10.4-10.9 | ≥780 | ≥9.8 | ≥1592 | ≥20 | 207-231 | 25-28 | 150 ℃ |

| 30SH | 1080-1130 | 11.3-11.7 | ≥804 | ≥10.1 | ≥1592 | ≥20 | 223-247 | 28-31 | 150 ℃ |

| 33SH | 1130-1170 | 11.3-11.7 | ≥844 | ≥10.6 | ≥1592 | ≥20 | 247-271 | 31-34 | 150 ℃ |

| 35SH | 1170-1220 | 11.7-12.2 | ≥876 | ≥11 | ≥1592 | ≥20 | 263-287 | 33-36 | 150 ℃ |

| 38SH | 1220-1250 | 12.2-12.5 | ≥907 | ≥10.5 | ≥1592 | ≥20 | 287-310 | 36-39 | 150 ℃ |

| 40SH | 1250-1280 | 12.5-12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 | 150 ℃ |

| 42SH | 1280-1320 | 12.8-13.2 | ≥971 | ≥12.2 | ≥1592 | ≥20 | 318-342 | 40-43 | 150 ℃ |

| 45SH | 1320-1370 | 13.2-13.7 | ≥979 | ≥12.3 | ≥1592 | ≥20 | 342-366 | 43-46 | 150 ℃ |

| 50SH | 1390-1440 | 13.9-14.4 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 374-406 | 47-51 | 150 ℃ |

| 52SH | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 390-422 | 49-53 | 150 ℃ |

| 28UH | 1020-1080 | 10.2-10.8 | ≥764 | ≥9.6 | ≥1990kii | ≥25 | 207-231 | 25-28 | 180℃ |

| 33UH | 1130-1170 | 11.3-11.7 | ≥812 | ≥10.2 | ≥1990kii | ≥25 | 247-271 | 31-34 | 180℃ |

| 35UH | 1170-1220 | 11.7-12.2 | ≥852 | ≥10.7 | ≥1990kii | ≥25 | 263-287 | 33-36 | 180℃ |

| 38UH | 1220-1250 | 12.2-12.5 | ≥860 | ≥10.8 | ≥1990kii | ≥25 | 287-310 | 36-39 | 180℃ |

| 40UH | 1250-1280 | 12.5-12.8 | ≥876 | ≥11.0 | ≥1990kii | ≥25 | 302-326 | 38-41 | 180℃ |

| 42UH | 1270-1320 | 12.7-13.2 | ≥971 | ≥12.2 | ≥1990kii | ≥25 | 310-342 | 39-43 | 180℃ |

| 50UH | 1390-1440 | 13.9-14.4 | ≥899 | ≥11.3 | ≥1990kii | ≥25 | 374-406 | 47-51 | 180℃ |

| 52UH | 1420-1470 | 14.2-14.7 | ≥899 | ≥11.3 | ≥1990kii | ≥25 | 390-422 | 49-53 | 180℃ |

| 28EH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | 25-28 | 200℃ |

| 30EH | 1080-1130 | 11.3-11.7 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-247 | 28-31 | 200℃ |

| 33EH | 1130-1170 | 11.3-11.7 | ≥820 | ≥10.3 | ≥2388 | ≥30 | 247-271 | 31-34 | 200℃ |

| 35EH | 1170-1220 | 11.7-12.2 | ≥836 | ≥10.5 | ≥2388 | ≥30 | 263-287 | 33-36 | 200℃ |

| 28AH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2706 | ≥34 | 207-231 | 25-28 | 230℃ |

| 30AH | 1070-1130 | 10.7-11.3 | ≥812 | ≥10.2 | ≥2706 | ≥34 | 215-247 | 27-31 | 230℃ |

| 33AH | 1110-1170 | 11.1-11.7 | ≥820 | ≥10.3 | ≥2706 | ≥34 | 239-271 | 30-34 | 230℃ |

Faahfaahinta baakadaha