Tsika Neodymium Magnets

Tsika neodymium magineti zvinoenderana nezvinodiwa nekambani yako. Isu tinotengesa ese mamakisi e neodymium magineti, maumbirwo etsika, saizi uye coating

Neodymium Magnets Mugadziri, fekitori muChina

HuizhouSravana Sameeralu Serial 4th Fullzen TechnologyCo., Ltd inyanzvineodymium magineti mugadziri, mugadziri wemagineti, fekitori, uye mutengesi muChina kubvira 2016. Isu takanyatso kuyedza, dhizaini, mainjiniya, kugadzira, kuongorora, uye kuunganidzwa kwetsika neodymium magineti. Customization kusangana nekambani yako zvinodiwa. Isu tinopa zvigadzirwa zvekunze-pasherufu pamwe chete neakagadziridzwa masevhisi, dhizaini yemagineti asingagumi, magineti akaumbwa neodymium, akagadzirirwa indasitiri yako.

Sarudza Yako Neodymium Magnets

Neodymium magineti vhidhiyo

Neodymium magineti sumo

Magineti yeNeodymium, inozivikanwawo seNdFeB magnet, ikristaro yeTetragonal crystal system yakagadzirwa neNd2Fe14B. Imagnetic material yakagadzirwa nesimbi praseodymium neodymium kuburikidza nekugadzirira uye sintering. Rudzi urwu rwemagneti ipermanent magnet ine magnetism yechipiri kune Absolute zero holmium magnet, uye ndiyo zvakare Rare-earth magnet inoshandiswa zvakanyanya.

Neodymium magineti makemikari kuumbwa

Neodymium iron boron zvachose magineti zvinhu inogara magineti zvinhu zvichibva pane intermetallic compound Nd2Fe14B. Zvikamu zvikuru zvinhu zvisingawanzo pasi neodymium (Nd), iron (Fe), uye boron (B). Chinhu chikuru chisingawanzwisisike chepasi ndeye neodymium (Nd), iyo inogona kutsiviwa neimwe isingawanzo simbi yepasi senge dysprosium (Dy) uye praseodymium (Pr) kuwana akasiyana zvivakwa. Simbi inogona zvakare kutsiviwa neimwe simbi senge cobalt (Co) uye aluminium (Al). Iyo boron yemukati idiki, asi inoita basa rakakosha mukugadzirwa kwe tetragonal crystal chimiro intermetallic compounds, zvichiita kuti makomisheni ave nepamusoro saturation magnetization, yakakwira uniaxial anisotropy, uye tembiricha yeCurie.

Neodymium magineti Maitiro ekuyerera

Process flow:batching → kunyunguduka uye kugadzira ingot/kukanda mucheka Izvo zvinongedzo ndizvo hwaro, uye sintering uye kudzikamisa ndiyo kiyi.

Maturusi ekugadzira uye maturusi ekuyedza ekuita zve neodymium iron boron magineti blanks:zvinosanganisira choto chekunyungudutsa, tambo yekukanda vira, muchina wekupwanya, mhepo inoyerera, compression molding muchina, vacuum packaging muchina, isostatic press muchina, sintering vira, kupisa kupisa vacuum choto, magineti performance tester, Gaussian mita.

Neodymium iron boron magineti machining maturusi:kugaya kusina pakati, muchina wekutenderedza, kupeta kaviri, kugaya, kugaya muchina, kugaya-mativi maviri, kucheka waya, bhenji kudhiraivha, kusagadzika kugaya, nezvimwe.

Neodymium magineti application

Sintered neodymium iron boron permanent magnet materials ine yakanakisa magineti zvinhu uye inoshandiswa zvakanyanya muminda yakadai semagetsi, magetsi muchina, midziyo yekurapa, matoyi, kurongedza, hardware michina, aerospace, etc. Zvakajairwa zvinosanganisira zvechigarire magineti mota, vatauri, magineti separators, komputa dhisiki madhiraivha, magineti resonance imaging emidziyo zviridzwa, nezvimwe.

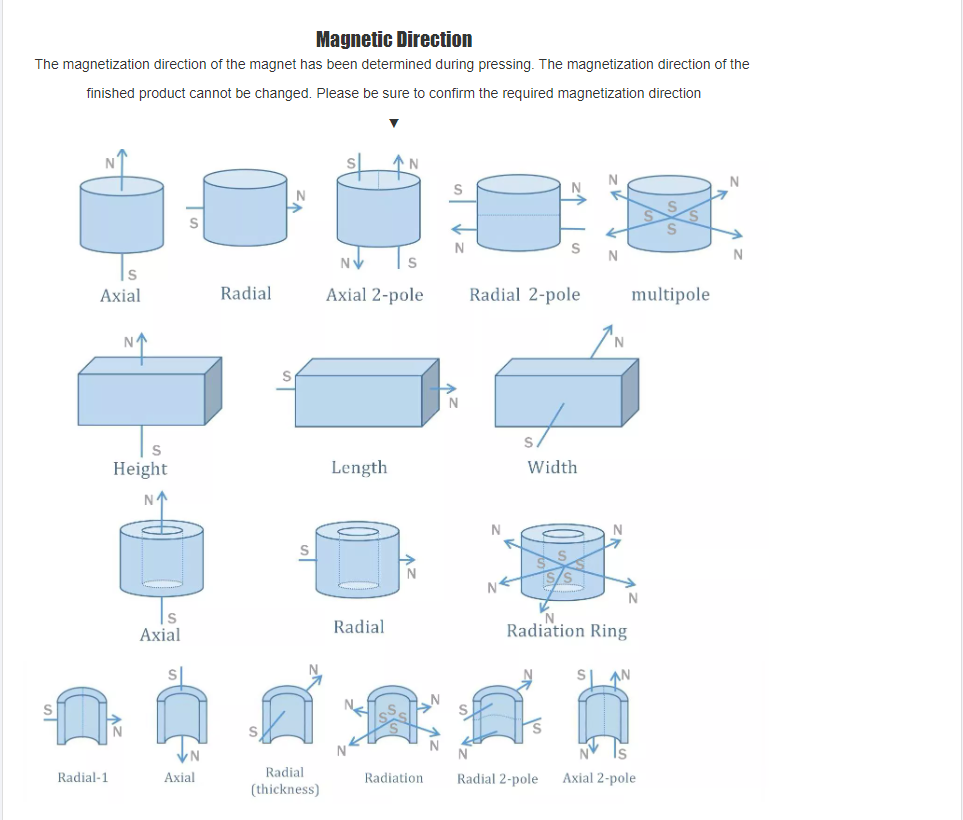

Neodymium magineti magnetization direction uyekupfeka kwepamusoro

Watadza kuwana zvauri kutsvaga?

Kazhinji, kune mastock eakajairwa neodymium magineti kana zvigadzirwa mudura redu. Asi kana iwe uine yakakosha kudiwa, isu tinopawo kugadzirisa sevhisi. Isu tinobvumawo OEM/ODM.

Tsika Neodymium Magnets

HuizhouSravana Sameeralu Serial 4th Fullzen TechnologyCo., Ltd inyanzvi inogadzira magineti. Kambani yedu tsika isingawanzo gigi magineti uye imwe yemhando yepamusoro yekugadzira magineti. Isu takanyanya mukuyedza, dhizaini, engineering, kugadzira, kuongorora uye kubatanidzatsika neodymium magineti. Kugadzirisa kuti usangane nezvinodiwa nekambani yako.Sezvinoratidzwa negwara rinotevera retsika, tinotengesa magineti akazara neodymium. Isu tinopa zvigadzirwa zvekunze-pasherufu pamwe neakagadziridzwa masevhisi, tsika isingaperi magineti, yakagadzirirwa-yakagadzirirwa indasitiri yako.Senge hombe neodymium arc magineti akagadzirirwa iwe.

Saizi uye chimiro:

Tinogona kupa customizeddisc, humburumbira, ring, sikweya cube, rectangular block, arc, countersunk, hoko uye mamwe asina kujairika magineti.

Kugadzira:

Tinoshandisa otomatikiequipmentskucheka uye kukuya zvigadzirwa kuti uite zviyero zvemagineti echigarire iwe aunoda, ine micro tolerance, kuti uwane iyo yekupedzisa mhedzisiro.

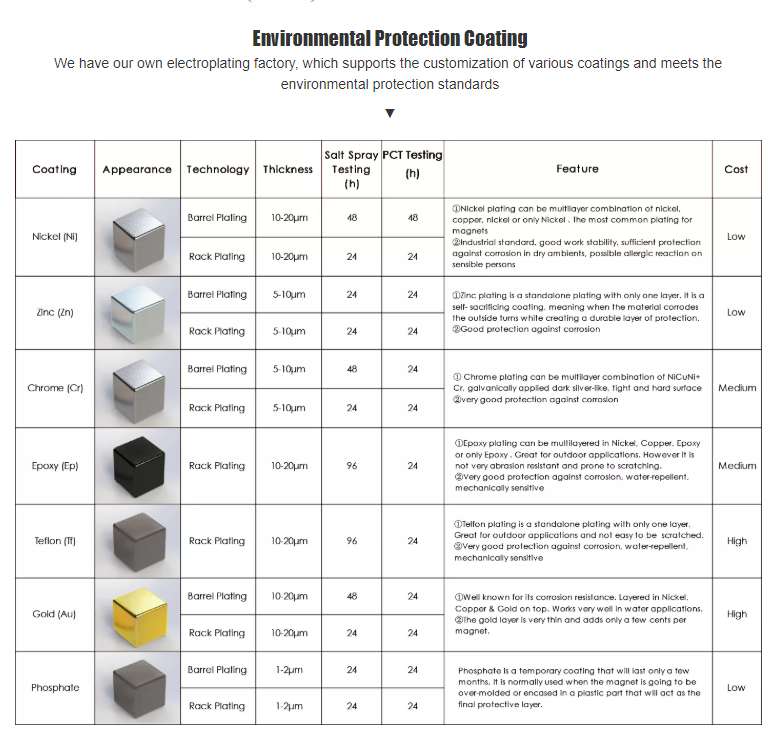

Surface treatment:

Magineti echigarire ari nyore kuve oxidized. Zvinoenderana nezvinodiwa nevatengi, nzvimbo yacho ichavharwa, epoxy coated kana electroplated kudzivirira ngura. Tinogona kupa nickel plating, galvanization, electrophoresis uye mamwe masevhisi.

Zvinyorwa zveTembiricha:

Permanent magineti inonzwa tembiricha. Tichanyatso gadzira zvinoenderana nezvinodiwa nemutengi zvemagineti echigarire ane tembiricha inopikisa.

Custom guide

| Material | Sintered Neodymium-Iron-Boron ( NdFeB ) | |

| Saizi | Custom | |

| Shape | Bkiya,Disc,Cylinder,Bar,Ring, Coutersunk, SegmentHzvakanaka,Ckumusoro,Trapezoid,Imaumbirwo asina kujairika, nezvimwewo. | |

| Performance | N33 N35 N38 N40 N42 N45 N48 N50 N52N54 nezvimwe. | |

| Coating | Zn, Ni-Cu-Ni, Ni, Ndarama, Sirivha, Mhangura, Epoxy, Chrome, nezvimwe | |

| Kushivirira saizi | ± 0.05mm yedhayamita/ukobvu, ± 0.1mm yehupamhi/hurefu | |

| Magnetization | Hukobvu Hune Magnetized, Axially Magnetized, Diametrally Magnetized, Multi-poles magnetized, Radial Magnetized. (Customzied chaiyo zvinodiwa magnetized) | |

| Max. Kushanda Tembiricha | Giredhi | Max. Operating Temperature |

| N35-N52 | 80°C (176°F) | |

| 33M- 48M | 100°C (212°F) | |

| 33H-48H | 120°C (248°F) | |

| 30SH-45SH | 150°C (302°F) | |

| 30UH-40UH | 180°C (356°F) | |

| 28EH-38EH | 200°C (392°F) | |

| 28AH-35AH | 220°C (428°F) | |

MOQ & Nguva Inotungamira

| Zvidimbu | Nguva Yekutungamira |

| 1000-10000 | 10 mazuva |

| 10000-100000 | 20 mazuva |

| 100000-1000000 | 30 mazuva |

Zvatinogona kukupa iwe…

Isu tiri nyanzvi Neodymium Magnet mugadziri uye mutengesi muChina. Tinogona kugadzira Neodymium Magnet (NdFeB magineti) maererano nezvaunoda.

Magnet performance

Iko kune kunyanya anotevera matatu ekuita ma parameter kuona mabatiro anoita magineti:

Remanence Br: Mushure mekunge magineti echigarire aitwa magineti kune tekinoroji saturation uye yekunze magineti yabviswa, iyo yakachengetwa Br inonzi yakasara magineti induction.

Kumanikidza simba Hc: Kudzikisa iyo B yeanogara magineti ane magineti kune tekinoroji saturation kusvika zero, inodiwa reverse remagineti simba inodaidzwa kuti magineti induction coercive simba, rakadimburirwa sesimba rekumanikidza.

Magnetic simba chigadzirwa BH: Inomiririra simba remagineti rakagadzwa nemagineti munzvimbo yepamhepo (nzvimbo iri pakati pemagineti mapango emagineti), kureva, iyo static magnetostatic simba pavhoriyamu yevhoriyamu yemhepo. Sezvo simba iri rakaenzana nechigadzirwa chemagnetti Bm neHm, inonzi iyo magineti simba chigadzirwa.

Tinogona kugadzirisa magineti echigarire ane zvivakwa pakatiN35-N54pamusika.

Parameter yeMagineti

| Giredhi | Remanence | Coercive Force | Intrinsic Coercive Force | Maximum Energy Product | Working Temp | ||||

| Br | Hcb | Hcj | BH max | Tw | |||||

| mT | KGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | ||

| N35 | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 80 ℃ |

| N38 | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | 80 ℃ |

| N40 | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥955 | ≥12 | 302-326 | 38-41 | 80 ℃ |

| N42 | 1280-1320 | 12.8-13.2 | ≥923 | ≥11.6 | ≥955 | ≥12 | 318-342 | 40-43 | 80 ℃ |

| N45 | 1320-1370 | 13.2-13.7 | ≥876 | ≥11.0 | ≥955 | ≥12 | 342-366 | 43-46 | 80 ℃ |

| N48 | 1370-1420 | 13.7-14.2 | ≥892 | ≥11.2 | ≥955 | ≥12 | 366-390 | 46-49 | 80 ℃ |

| N50 | 1390-1440 | 13.9-14.4 | ≥836 | ≥10.5 | ≥955 | ≥12 | 374-406 | 47-51 | 80 ℃ |

| N52 | 1420-1470 | 14.2-14.7 | ≥836 | ≥10.5 | ≥876 | ≥11 | 390-422 | 49-53 | 80 ℃ |

| N55 | 1460-1520 | 14.6-15.2 | ≥716 | ≥9 | ≥876 | ≥11 | 414-446 | 52-56 | 80 ℃ |

| 35M | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 100 ℃ |

| 38M | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | 100 ℃ |

| 40M | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | 100 ℃ |

| 42M | 1280-1320 | 12.8-13.2 | ≥995 | ≥12.0 | ≥1114 | ≥14 | 318-342 | 40-43 | 100 ℃ |

| 45M | 1320-1370 | 13.2-13.7 | ≥995 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 | 100 ℃ |

| 48M | 1360-1420 | 13.6-14.2 | ≥1019 | ≥12.8 | ≥1114 | ≥14 | 366-390 | 46-49 | 100 ℃ |

| 50M | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1114 | ≥14 | 374-406 | 47-51 | 100 ℃ |

| 52M | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1035 | ≥13 | 390-422 | 49-53 | 100 ℃ |

| 33H | 1130-1170 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1353 | ≥17 | 247-271 | 31-34 | 120 ℃ |

| 35H | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 120 ℃ |

| 38H | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 | 120 ℃ |

| 40H | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | 120 ℃ |

| 42H | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 318-342 | 40-43 | 120 ℃ |

| 45H | 1320-1370 | 13.2-13.7 | ≥971 | ≥12.2 | ≥1353 | ≥17 | 342-366 | 43-46 | 120 ℃ |

| 48H | 1360-1420 | 13.6-14.2 | ≥1027 | ≥12.9 | ≥1353 | ≥17 | 366-390 | 46-49 | 120 ℃ |

| 50H | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 374-406 | 47-51 | 120 ℃ |

| 52H | 1420-1470 | 14.2-14.7 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 390-422 | 49-53 | 120 ℃ |

| 28SH | 1040-1090 | 10.4-10.9 | ≥780 | ≥9.8 | ≥1592 | ≥20 | 207-231 | 25-28 | 150 ℃ |

| 30SH | 1080-1130 | 11.3-11.7 | ≥804 | ≥10.1 | ≥1592 | ≥20 | 223-247 | 28-31 | 150 ℃ |

| 33SH | 1130-1170 | 11.3-11.7 | ≥844 | ≥10.6 | ≥1592 | ≥20 | 247-271 | 31-34 | 150 ℃ |

| 35SH | 1170-1220 | 11.7-12.2 | ≥876 | ≥11 | ≥1592 | ≥20 | 263-287 | 33-36 | 150 ℃ |

| 38SH | 1220-1250 | 12.2-12.5 | ≥907 | ≥10.5 | ≥1592 | ≥20 | 287-310 | 36-39 | 150 ℃ |

| 40SH | 1250-1280 | 12.5-12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 | 150 ℃ |

| 42SH | 1280-1320 | 12.8-13.2 | ≥971 | ≥12.2 | ≥1592 | ≥20 | 318-342 | 40-43 | 150 ℃ |

| 45SH | 1320-1370 | 13.2-13.7 | ≥979 | ≥12.3 | ≥1592 | ≥20 | 342-366 | 43-46 | 150 ℃ |

| 50SH | 1390-1440 | 13.9-14.4 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 374-406 | 47-51 | 150 ℃ |

| 52SH | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 390-422 | 49-53 | 150 ℃ |

| 28UH | 1020-1080 | 10.2-10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | 25-28 | 180 ℃ |

| 33UH | 1130-1170 | 11.3-11.7 | ≥812 | ≥10.2 | ≥1990 | ≥25 | 247-271 | 31-34 | 180 ℃ |

| 35UH | 1170-1220 | 11.7-12.2 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 263-287 | 33-36 | 180 ℃ |

| 38UH | 1220-1250 | 12.2-12.5 | ≥860 | ≥10.8 | ≥1990 | ≥25 | 287-310 | 36-39 | 180 ℃ |

| 40UH | 1250-1280 | 12.5-12.8 | ≥876 | ≥11.0 | ≥1990 | ≥25 | 302-326 | 38-41 | 180 ℃ |

| 42UH | 1270-1320 | 12.7-13.2 | ≥971 | ≥12.2 | ≥1990 | ≥25 | 310-342 | 39-43 | 180 ℃ |

| 50UH | 1390-1440 | 13.9-14.4 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 374-406 | 47-51 | 180 ℃ |

| 52UH | 1420-1470 | 14.2-14.7 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 390-422 | 49-53 | 180 ℃ |

| 28EH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | 25-28 | 200 ℃ |

| 30EH | 1080-1130 | 11.3-11.7 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-247 | 28-31 | 200 ℃ |

| 33EH | 1130-1170 | 11.3-11.7 | ≥820 | ≥10.3 | ≥2388 | ≥30 | 247-271 | 31-34 | 200 ℃ |

| 35EH | 1170-1220 | 11.7-12.2 | ≥836 | ≥10.5 | ≥2388 | ≥30 | 263-287 | 33-36 | 200 ℃ |

| 28AH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2706 | ≥34 | 207-231 | 25-28 | 230 ℃ |

| 30AH | 1070-1130 | 10.7-11.3 | ≥812 | ≥10.2 | ≥2706 | ≥34 | 215-247 | 27-31 | 230 ℃ |

| 33AH | 1110-1170 | 11.1-11.7 | ≥820 | ≥10.3 | ≥2706 | ≥34 | 239-271 | 30-34 | 230 ℃ |

Packaging details