Maginito Amakonda Neodymium

Maginito a neodymium malinga ndi zomwe kampani yanu ikufuna. Timagulitsa magiredi onse a neodymium maginito, mawonekedwe, makulidwe ndi zokutira

Wopanga maginito a Neodymium, fakitale ku China

HuizhouUkadaulo wa FullzenCo., Ltd ndi katswirineodymium maginito wopanga, makina opanga maginito, fakitale, ndi ogulitsa ku China kuyambira 2016. Ndife apadera pakuyesa, kupanga, zomangamanga, kupanga, kuyang'anira, ndi kusonkhanitsa maginito a neodymium. Kusintha mwamakonda kuti mukwaniritse zomwe kampani yanu ikufuna. Timapereka zinthu zapashelufu komanso ntchito zosinthidwa makonda, kapangidwe kake ka maginito okhazikika, maginito a neodymium opangidwa mwaluso, opangira bizinesi yanu.

Sankhani Maginito Anu a Neodymium

Neodymium maginito kanema

Chiyambi cha maginito a Neodymium

Neodymium maginito, yemwenso amadziwika kuti NdFeB maginito, ndi Tetragonal crystal system crystal yopangidwa ndi Nd2Fe14B. Ndi maginito opangidwa kuchokera ku zitsulo za praseodymium neodymium pokonzekera ndi kupukuta. Maginito amtunduwu ndi maginito okhazikika omwe maginito ake ndi achiwiri kwa Absolute zero holmium maginito, komanso ndi maginito omwe amagwiritsidwa ntchito kwambiri ndi Rare-earth maginito.

Neodymium maginito mankhwala

Neodymium iron boron okhazikika maginito chuma ndi okhazikika maginito zakuthupi zochokera intermetallic pawiri Nd2Fe14B. Zigawo zazikuluzikulu ndizosowa zapadziko lapansi neodymium (Nd), chitsulo (Fe), ndi boron (B). Chinthu chachikulu chapadziko lapansi chosowa kwambiri ndi neodymium (Nd), chomwe chitha kusinthidwa pang'ono ndi zitsulo zina zapadziko lapansi monga dysprosium (Dy) ndi praseodymium (Pr) kuti mupeze zinthu zosiyanasiyana. Iron imathanso kusinthidwa pang'ono ndi zitsulo zina monga cobalt (Co) ndi aluminiyamu (Al). Boron zili ndi zochepa, koma zimagwira ntchito yofunika kwambiri pakupanga ma tetragonal crystal structure intermetallic compounds, zomwe zimapangitsa kuti mankhwalawa akhale ndi maginito amphamvu kwambiri, apamwamba a uniaxial anisotropy, ndi kutentha kwa Curie.

Neodymium maginito Njira ikuyenda

Njira yoyenda:batching → kusungunula ndi kupanga ingot/kuponya zingwe → kupanga ufa → kuumba → kutenthetsa ndi kutenthetsa → kuyezetsa maginito → kukonza kugaya → kukonza pini → electroplating → kumaliza mankhwala. Zosakaniza ndizo maziko, ndipo sintering ndi kutentha ndizofunikira.

Zida zopangira ndi zida zoyezera magwiridwe antchito a neodymium iron boron maginito opanda kanthu:kuphatikiza ng'anjo yosungunuka, ng'anjo yoponyera mizere, makina ophwanyira, mphero yotulutsa mpweya, makina opangira makina, makina ojambulira vacuum, makina osindikizira a isostatic, ng'anjo yamoto, ng'anjo yoyezera kutentha, choyesa maginito, mita ya Gaussian.

Neodymium iron boron magnet Machining zida:makina opukutira opanda pakati, makina ozungulira, akupera pawiri, akupera lathyathyathya, makina ocheka, akupera mbali ziwiri, kudula waya, kubowola benchi, kugaya kosakhazikika, etc.

Neodymium maginito ntchito

Sintered neodymium iron boron okhazikika maginito zipangizo ali ndi makhalidwe abwino kwambiri maginito ndipo chimagwiritsidwa ntchito m'madera monga zamagetsi, mphamvu makina, zipangizo zachipatala, zidole, ma CD, hardware makina, Azamlengalenga, etc. Wamba monga okhazikika maginito Motors, okamba, olekanitsa maginito, kompyuta litayamba abulusa, maginito resonance kulingalira zida zida, etc.

Neodymium maginito magnetization malangizo ndichophimba pamwamba

Simunapeze zomwe mukuyang'ana?

Kawirikawiri, mu nyumba yathu yosungiramo zinthu muli maginito a neodymium kapena zipangizo zopangira zinthu. Koma ngati mukufuna zinthu zapadera, timaperekanso chithandizo chosintha zinthu. Timalandiranso OEM/ODM.

Maginito Amakonda Neodymium

HuizhouUkadaulo wa FullzenCo., Ltd ndi katswiri wopanga maginito. Kampani yathu imakonda maginito osowa padziko lapansi komanso imodzi mwazinthu zapamwamba kwambiri za maginito opanga maginito. Timakhala okhazikika pakuyesa, kupanga, uinjiniya, kupanga, kuyang'anira ndi kusonkhanitsamaginito a neodymium. Kusintha mwamakonda kuti mukwaniritse zomwe kampani yanu ikufuna.Monga momwe kalozera wotsatira akuwonetsa, timagulitsa maginito athunthu a neodymium. Timapereka zinthu zapashelufu komanso ntchito zosinthidwa makonda, maginito okhazikika, opangira mafakitale anu.Monga maginito akuluakulu a neodymium arc okonzera inu.

Kukula ndi mawonekedwe:

Titha kupereka makondadiski, yamphamvu, mphete, lalikulu kyubu, chipika amakona anayi, arc, countersunk, mbedza ndi maginito ena osakhazikika okhazikika.

Kupanga:

Timagwiritsa ntchito makinazidakudula ndi pogaya zipangizo kupanga miyeso ya maginito okhazikika mukufuna, ndi yaying'ono kulolerana, kukwaniritsa zotsatira kumaliza.

Chithandizo chapamwamba:

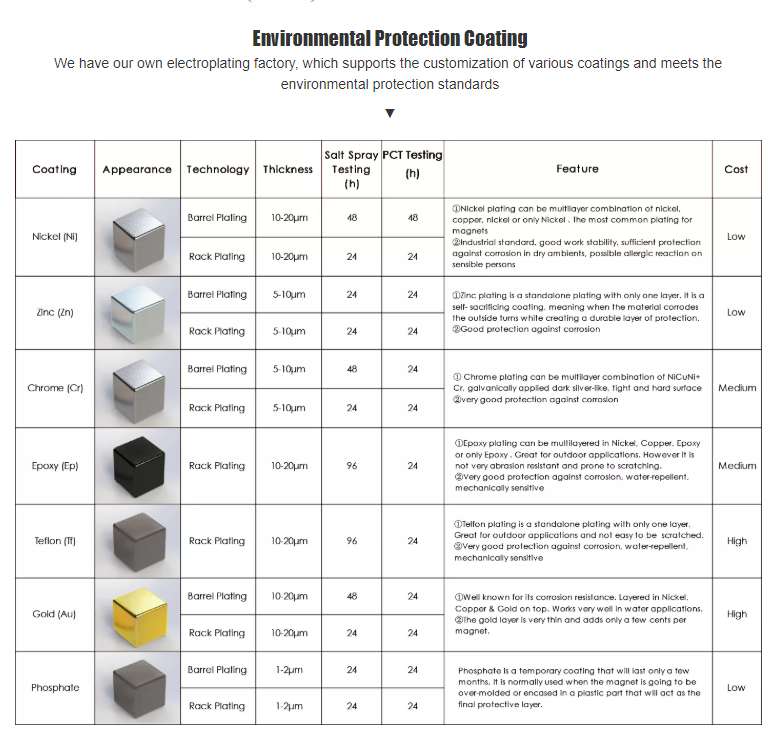

Maginito osatha ndi osavuta kukhala oxidized. Malinga ndi zosowa za makasitomala, pamwamba padzakhala yokutidwa, yokutidwa ndi epoxy kapena electroplated kuteteza dzimbiri. Titha kupereka nickel plating, galvanization, electrophoresis ndi ntchito zina.

Zolemba za Kutentha:

Permanent maginito ndi kutentha kwambiri. Tidzapanga mosamalitsa malinga ndi zomwe makasitomala amafuna maginito okhazikika okhala ndi kukana kutentha kwambiri.

Buku lowongolera mwamakonda

| Zakuthupi | Sintered Neodymium-Iron-Boron (NdFeB) | |

| Kukula | Mwambo | |

| Maonekedwe | Bloko,Dndi,Cylinder,Bayi,Rndi, Ckunja, GawoHchabwino,Cmmwamba,Trapezoid,inemawonekedwe okhazikika, etc. | |

| Kachitidwe | N33 N35 N38 N40 N42 N45 N48 N50 N52N54 ndi. | |

| Kupaka | Zn, Ni-Cu-Ni, Ni, Gold, Silver, Copper, Epoxy, Chrome, etc | |

| Kulekerera kukula | ± 0.05mm kwa diamater / makulidwe, ± 0.1mm m'lifupi / kutalika | |

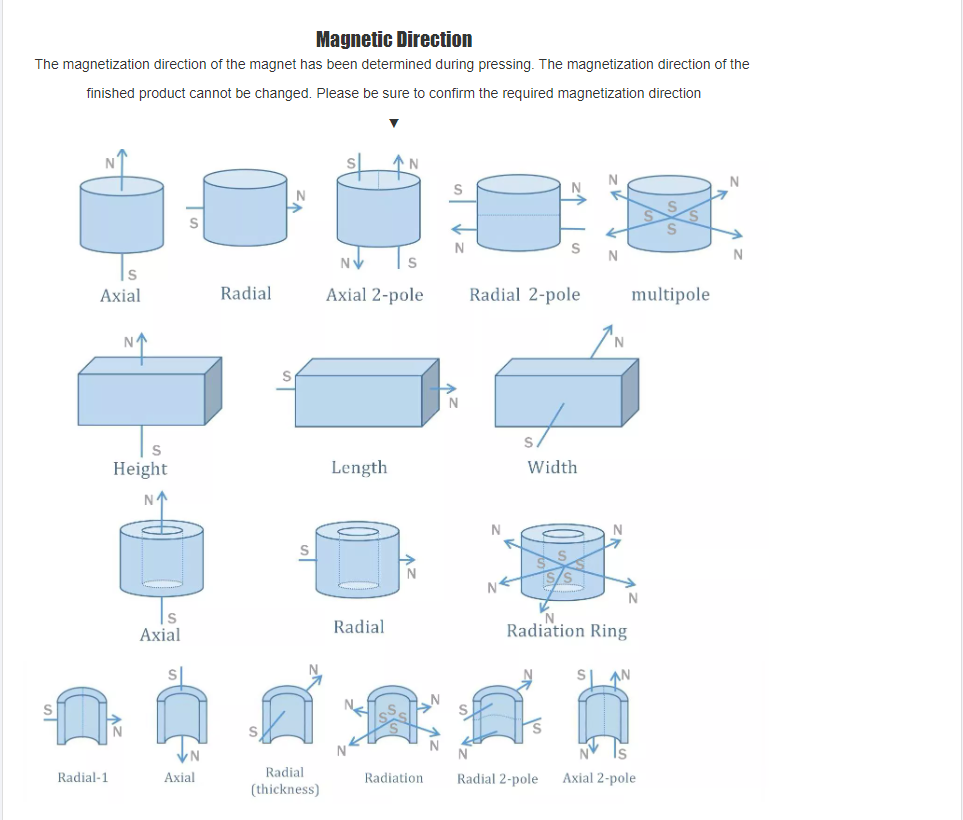

| Magnetization | Makulidwe Amaginito, Axially Magnetized, Diametrally Magnetized, Multi-poles magnetized, Radial Magnetized. (Zofunikira zenizeni za magnetized) | |

| Max. Kutentha kwa Ntchito | Gulu | Max. Kutentha kwa Ntchito |

| N35-N52 | 80°C (176°F) | |

| 33M-48M | 100°C (212°F) | |

| 33H-48H | 120°C (248°F) | |

| Mtengo wa 30SH-45SH | 150°C (302°F) | |

| 30UH-40UH | 180°C (356°F) | |

| 28EH-38EH | 200°C (392°F) | |

| 28AH-35AH | 220°C (428°F) | |

MOQ & Nthawi Yotsogolera

| Zidutswa | Nthawi yotsogolera |

| 1000-10000 | 10 masiku |

| 10000-100000 | 20 masiku |

| 100000-1000000 | 30 masiku |

Zomwe tingakupatseni…

Ndife akatswiri opanga maginito a Neodymium ndi ogulitsa ku China. Titha kupanga Neodymium maginito (NdFeB maginito) malinga ndi zofuna zanu.

Kuchita kwa maginito

Pali makamaka magawo atatu otsatirawa ogwirira ntchito kuti adziwe momwe maginito amagwirira ntchito:

Remanence Br: Maginito okhazikika akapangidwa ndi maginito kuti achuluke komanso mphamvu ya maginito yakunja ikachotsedwa, Br yosungidwayo imatchedwa yotsalira maginito induction.

Mphamvu yokakamiza Hc: Kuti muchepetse B wa maginito okhazikika opangidwa ndi maginito kuti afikire ziro, mphamvu yosinthira maginito imatchedwa mphamvu yamaginito yokakamiza, yofupikitsidwa ngati mphamvu yokakamiza.

Magnetic energy product BH: Imayimira mphamvu ya maginito yomwe imakhazikitsidwa ndi maginito mumlengalenga (danga lomwe lili pakati pa mitengo iwiri ya maginito ya maginito), ndiye kuti, mphamvu ya static magnetostatic pa voliyumu yagawo la mpweya. Popeza mphamvuyi ndi yofanana ndi maginito a Bm ndi Hm, amatchedwa maginito mphamvu mankhwala.

Tikhoza makonda maginito okhazikika ndi katundu pakatiN35-N54pamsika.

Chigawo cha maginito

| Gulu | Kubwerera m'mbuyo | Mphamvu Yokakamiza | Mphamvu Yokakamiza Yamkati | Maximum Energy Product | Ntchito Temp | ||||

| Br | Hcb | Hcj | BH max | Tw | |||||

| mT | KGs | kA/m | k Iwo | kA/m | k Iwo | kJ/m3 | MGOe | ||

| N35 | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 80 ℃ |

| N38 | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | 80 ℃ |

| N40 | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥955 | ≥12 | 302-326 | 38-41 | 80 ℃ |

| N42 | 1280-1320 | 12.8-13.2 | ≥923 | ≥11.6 | ≥955 | ≥12 | 318-342 | 40-43 | 80 ℃ |

| N45 | 1320-1370 | 13.2-13.7 | ≥876 | ≥11.0 | ≥955 | ≥12 | 342-366 | 43-46 | 80 ℃ |

| N48 | 1370-1420 | 13.7-14.2 | ≥892 | ≥11.2 | ≥955 | ≥12 | 366-390 | 46-49 | 80 ℃ |

| N50 | 1390-1440 | 13.9-14.4 | ≥836 | ≥10.5 | ≥955 | ≥12 | 374-406 | 47-51 | 80 ℃ |

| N52 | 1420-1470 | 14.2-14.7 | ≥836 | ≥10.5 | ≥876 | ≥11 | 390-422 | 49-53 | 80 ℃ |

| N55 | 1460-1520 | 14.6-15.2 | ≥716 | ≥9 | ≥876 | ≥11 | 414-446 | 52-56 | 80 ℃ |

| 35 m | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 100 ℃ |

| 38m | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | 100 ℃ |

| 40M | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | 100 ℃ |

| 42M | 1280-1320 | 12.8-13.2 | ≥995 | ≥12.0 | ≥1114 | ≥14 | 318-342 | 40-43 | 100 ℃ |

| 45m | 1320-1370 | 13.2-13.7 | ≥995 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 | 100 ℃ |

| 48m | 1360-1420 | 13.6-14.2 | ≥1019 | ≥12.8 | ≥1114 | ≥14 | 366-390 | 46-49 | 100 ℃ |

| 50M | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1114 | ≥14 | 374-406 | 47-51 | 100 ℃ |

| 52M | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1035 | ≥13 | 390-422 | 49-53 | 100 ℃ |

| 33H | 1130-1170 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1353 | ≥17 | 247-271 | 31-34 | 120℃ |

| 35H pa | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 120℃ |

| 38H pa | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 | 120℃ |

| 40H pa | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | 120℃ |

| 42H pa | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 318-342 | 40-43 | 120℃ |

| 45H | 1320-1370 | 13.2-13.7 | ≥971 | ≥12.2 | ≥1353 | ≥17 | 342-366 | 43-46 | 120℃ |

| 48H pa | 1360-1420 | 13.6-14.2 | ≥1027 | ≥12.9 | ≥1353 | ≥17 | 366-390 | 46-49 | 120℃ |

| 50H | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 374-406 | 47-51 | 120℃ |

| 52H pa | 1420-1470 | 14.2-14.7 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 390-422 | 49-53 | 120℃ |

| 28SH ndi | 1040-1090 | 10.4-10.9 | ≥780 | ≥9.8 | ≥1592 | ≥20 | 207-231 | 25-28 | 150 ℃ |

| 30 SH | 1080-1130 | 11.3-11.7 | ≥804 | ≥10.1 | ≥1592 | ≥20 | 223-247 | 28-31 | 150 ℃ |

| 33SH ndi | 1130-1170 | 11.3-11.7 | ≥844 | ≥10.6 | ≥1592 | ≥20 | 247-271 | 31-34 | 150 ℃ |

| 35SH ndi | 1170-1220 | 11.7-12.2 | ≥876 | ≥11 | ≥1592 | ≥20 | 263-287 | 33-36 | 150 ℃ |

| 38SH ndi | 1220-1250 | 12.2-12.5 | ≥907 | ≥10.5 | ≥1592 | ≥20 | 287-310 | 36-39 | 150 ℃ |

| 40SH ndi | 1250-1280 | 12.5-12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 | 150 ℃ |

| 42SH ndi | 1280-1320 | 12.8-13.2 | ≥971 | ≥12.2 | ≥1592 | ≥20 | 318-342 | 40-43 | 150 ℃ |

| 45SH ndi | 1320-1370 | 13.2-13.7 | ≥979 | ≥12.3 | ≥1592 | ≥20 | 342-366 | 43-46 | 150 ℃ |

| 50 SH | 1390-1440 | 13.9-14.4 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 374-406 | 47-51 | 150 ℃ |

| 52SH ndi | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 390-422 | 49-53 | 150 ℃ |

| 28 UH | 1020-1080 | 10.2-10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | 25-28 | 180 ℃ |

| 33 UH | 1130-1170 | 11.3-11.7 | ≥812 | ≥10.2 | ≥1990 | ≥25 | 247-271 | 31-34 | 180 ℃ |

| 35 UH | 1170-1220 | 11.7-12.2 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 263-287 | 33-36 | 180 ℃ |

| 38 uwu | 1220-1250 | 12.2-12.5 | ≥860 | ≥10.8 | ≥1990 | ≥25 | 287-310 | 36-39 | 180 ℃ |

| 40 UH | 1250-1280 | 12.5-12.8 | ≥876 | ≥11.0 | ≥1990 | ≥25 | 302-326 | 38-41 | 180 ℃ |

| 42UH | 1270-1320 | 12.7-13.2 | ≥971 | ≥12.2 | ≥1990 | ≥25 | 310-342 | 39-43 | 180 ℃ |

| 50 UH | 1390-1440 | 13.9-14.4 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 374-406 | 47-51 | 180 ℃ |

| 52 UH | 1420-1470 | 14.2-14.7 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 390-422 | 49-53 | 180 ℃ |

| 28EH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | 25-28 | 200 ℃ |

| 30 EH | 1080-1130 | 11.3-11.7 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-247 | 28-31 | 200 ℃ |

| 33 EH | 1130-1170 | 11.3-11.7 | ≥820 | ≥10.3 | ≥2388 | ≥30 | 247-271 | 31-34 | 200 ℃ |

| 35 EH | 1170-1220 | 11.7-12.2 | ≥836 | ≥10.5 | ≥2388 | ≥30 | 263-287 | 33-36 | 200 ℃ |

| 28AH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2706 | ≥34 | 207-231 | 25-28 | 230 ℃ |

| 30H pa | 1070-1130 | 10.7-11.3 | ≥812 | ≥10.2 | ≥2706 | ≥34 | 215-247 | 27-31 | 230 ℃ |

| 33H pa | 1110-1170 | 11.1-11.7 | ≥820 | ≥10.3 | ≥2706 | ≥34 | 239-271 | 30-34 | 230 ℃ |

Tsatanetsatane wapaketi