Neodymium Arc Magnets Custom

Neodymium arc magnets, or neodymium segment magnets, can be seen as a part of neodymium ring magnets or neodymium disc magnets. They are made of high-quality neodymium magnets containing the elements neodymium, iron, and boron. NdFeB magnets are permanent magnets and the most widely used type of rare earth magnets.

Neodymium Arc Magnets Manufacturer,factory In China

Strong Neodymium Arc magnets are used in building motors, generators, or magnetic bearings. Since neodymium magnets N35, N36, N42, N45, 50 & N52 are much stronger than other magnets, using strong neodymium magnets can build much more powerful motors, and generators than ever.

We have staffed with a team of experienced professionals in Rare Earth Neodymium Magnets and Magnetic Assemblies. As a provider of strategic supply, we have the unique capability to meet the requests of all of our customers.

We are professional Neodymium Magnet manufacturer and supplier in China. We can produce Neodymium Magnet (NdFeB magnet) according to your requirements. Please contact us right now.

Custom Your Neodymium Arc Magnets

Couldn’t find what you looking for?

Generally, there are stocks of common neodymium magnets or raw materials in our warehouse. But if you have special demand, we also provide customization service. We also accept OEM/ODM.

What we can offer you…

FAQs

Arc magnets are often referred to as tile magnets, being most commonly used in electric motors, generators, and torque couplings due to the configuration of their north and south polarities. They can even be found in sensors and holding applications.

Neodymium arc magnets are mostly used in voice coil motor, permanent magnet motors, generators, wind turbines, torque couplings, and other applications.

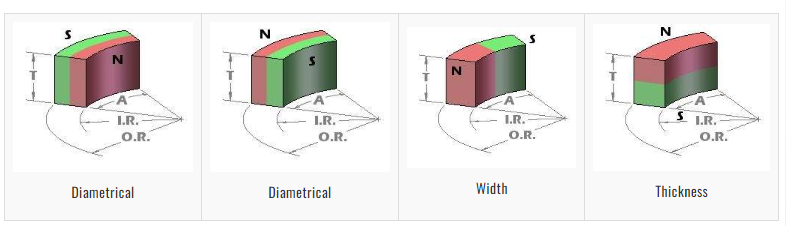

Neodymium arc magnet for frequently-used radial flux motor is magnetized through diametrical direction and definitely used in pairs. It should be noted that pure radially magnetized Neodymium arc magnets are extremely difficult to manufacture. Fan-shaped arc magnet is commonly served as axial flux motor magnet. For some axial flux motor, a certain quantity of chord magnetized magnet should be placed between regular axially magnetized magnet to form a Halbach array, then obtain more ideal magnetic field strength and distribution.

The vast majority of Neodymium arc magnet serve as motor magnet. Besides magnetic performance and surface protective treatment, both shape and structure of the magnet have significantly impacts on the motor performance.

It is a challenge for slotted motor to avoid cogging torque caused by interaction between the magnet and the stator tooth. In order to suppress torque ripple, vibration, and noise generated by cogging torque, curved magnet in either frequently-used radial flux motor or axial flux motor can be modified into the skewed shape. Eddy current is generally leading the temperature rise in the permanent magnet and caused demagnetization. Hence decreased the working efficiency of the motor.

Laminated arc magnet which made by bonding several pieced of thin magnet together can dramatically reduce the eddy current loss without replacing the original structure and performance of the motor.

Excellent finish

Elevated durability

Easy to install