Magneta Neodymii Consuetudinaria

Magneta neodymii secundum necessitates societatis vestrae facta. Omnia genera magnetorum neodymii, formas, magnitudines et tegumenta singularia vendimus.

Fabricator Magnetum Neodymii, officina in Sinis

HuizhouTechnologia FullzenCo., Ltd est professionalisfabricator magnetis neodymii, fabricator magnetum ad usum singulorum, officina, et provisor in Sinis ab anno 2016. In experimentatione, designatione, machinatione, fabricatione, inspectione, et compositione magnetum neodymii ad usum singulorum periti sumus. Customizatio ad requisita societatis vestrae occurrenda. Offerimus producta parata necnon officia ad usum singulorum, designationem ad usum singulorum magnetum permanentium, magneta neodymii forma ad usum singulorum, ad industriam vestram apte confecta.

Elige Magnetes Neodymii Tuos

Video magnetis neodymii

Introductio magnetium neodymii

Magnetes neodymii, etiam magnes NdFeB appellatus, est systema crystallinum tetragonale ex Nd2Fe14B formatum. Materia magnetica est ex metallo praseodymii neodymii per praeparationem et sinterizationem fabricata. Hoc genus magnetis est magnes permanens cuius magnetismus secundum solum magneti holmio zero absoluto est, et etiam est magnes terrae rarae frequentissime adhibitus.

Compositio chemica magnetium neodymii

Materia magnetis permanentis neodymii ferro-bori est materia magnetis permanentis fundata in composito intermetallico Nd₂Fe₄B. Componentes principales sunt elementa terrae rarae, neodymium (Nd), ferrum (Fe), et borum (B). Elementum terrae rarae praecipuum est neodymium (Nd), quod partim substitui potest aliis metallis terrae rarae, ut dysprosio (Dy) et praseodymio (Pr), ut proprietates diversas obtineantur. Ferrum etiam partim substitui potest aliis metallis, ut cobalto (Co) et aluminio (Al). Contentum bori parvum est, sed munus magnum agit in formatione compositorum intermetallicorum structurae crystallinae tetragonalis, ita ut composita magnam saturationis magnetizationem, magnam anisotropiam uniaxialem, et altam temperaturam Curie habeant.

Magneta Neodymii Fluxus Processus

Fluxus processus:Confectio partium → liquefactio et lingotorum fabricatio/iactura taeniarum → pulveris fabricatio → formatio formans → sinterizatio et temperatio → probatio magnetica → tractatio triturae → tractatio secandi aciculi → galvanoplastia → productum perfectum. Ingredientia sunt fundamentum, et sinterizatio et temperatio sunt clavis.

Instrumenta productionis et instrumenta probationis efficaciae pro magneticis neodymii ferro-bori:inter quas fornax liquefaciens, fornax iaciens taeniarum, machina contundendi, mola fluxus aeris, machina formandi per compressionem, machina involucri vacui, machina preli isostatica, fornax sinterizationis, fornax vacui tractationis caloris, probator perfunctionis magneticae, metrum Gaussianum.

Instrumenta machinationis magnetis neodymii ferro bori:Tritura sine centro, machina rotundans, tritura utrinque, tritura plana, machina secans, tritura utrinque, sectio filorum, terebra scamni, tritura irregularis, etc.

Applicationes magnetium neodymii

Materiae magnetis permanentis neodymii ferro-bori sinterizatae proprietates magneticas excellentes habent et late in campis ut electronicis, machinis potentiae, apparatu medico, ludicris, involucris, machinis ferramentalibus, industria aerospatiali, et cetera adhibentur. Inter communes sunt motores magnetis permanentis, oratores, separatores magnetici, lectores discorum computatralium, instrumenta resonantiae magneticae, et cetera.

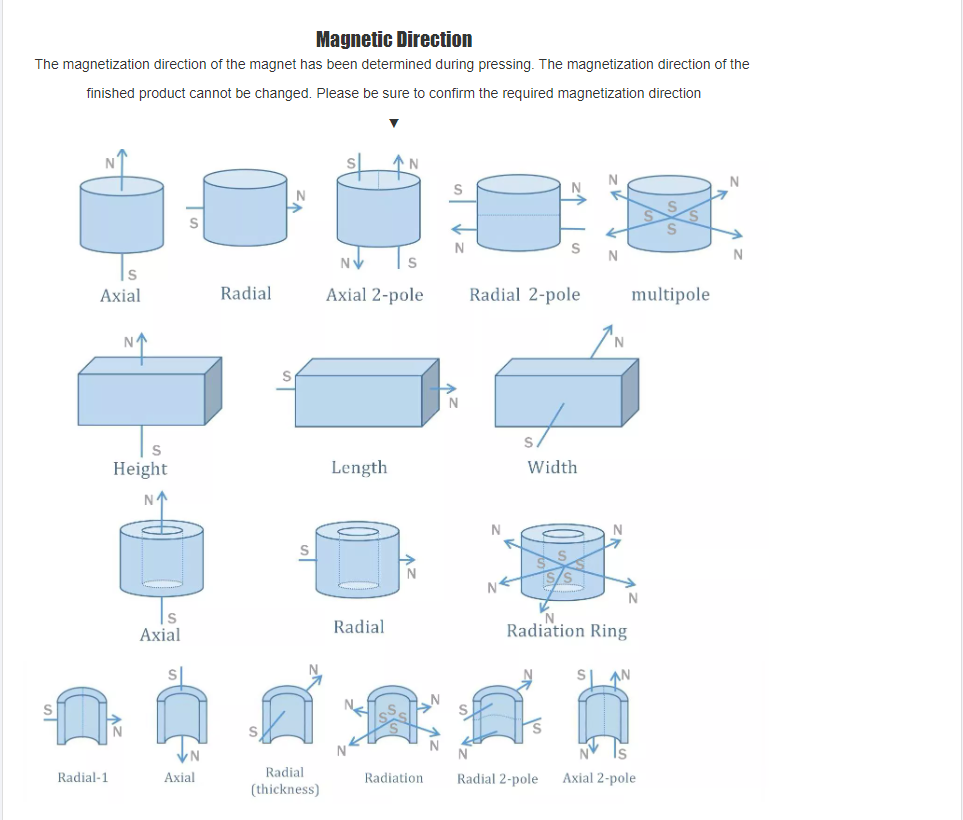

Directio magnetizationis magnetorum neodymii ettegumentum superficiei

Nonne invenire potuisti quod quaerebas?

Generaliter, copiae magnetorum neodymii communium vel materiarum rudis in horreo nostro sunt. Sed si postulationem specialem habes, etiam officia customizationis praebemus. OEM/ODM quoque accipimus.

Magneta Neodymii Consuetudinaria

HuizhouTechnologia FullzenSocietas nostra, Ltd., fabricator magnetum professionalis est. Societas nostra magnetes terrarum rararum ad usum fabricat et unus ex optimis fabricatoribus magnetum ad usum fabricatorum. In experimentis, designatione, arte ingeniaria, fabricatione, inspectione et compositione magnetum specializamur.Magneta neodymii facta ad usumAdaptatio ad requisita societatis tuae. Ut sequens dux personalizationis demonstrat, magneta neodymii completa vendimus. Producta parata necnon officia personalizata, magneta permanentia personalizata, ad industriam tuam apte facta, offerimus. Exempli gratia, magneta arcus neodymii magni tibi aptata.

Magnitudo et forma:

Possumus praebere personalizatumdiscus, cylindrus, anulus, cubus quadratus, quadra rectangula, arcus, concavus, hamus et alii magnetes permanentes irregulares.

Fabricatio:

Automatione utimurapparatusAd materias rudis secandum et terendum ut dimensiones magnetis permanentis quas vis, cum tolerantia minima, efficias, ad effectum perfectum consequendum.

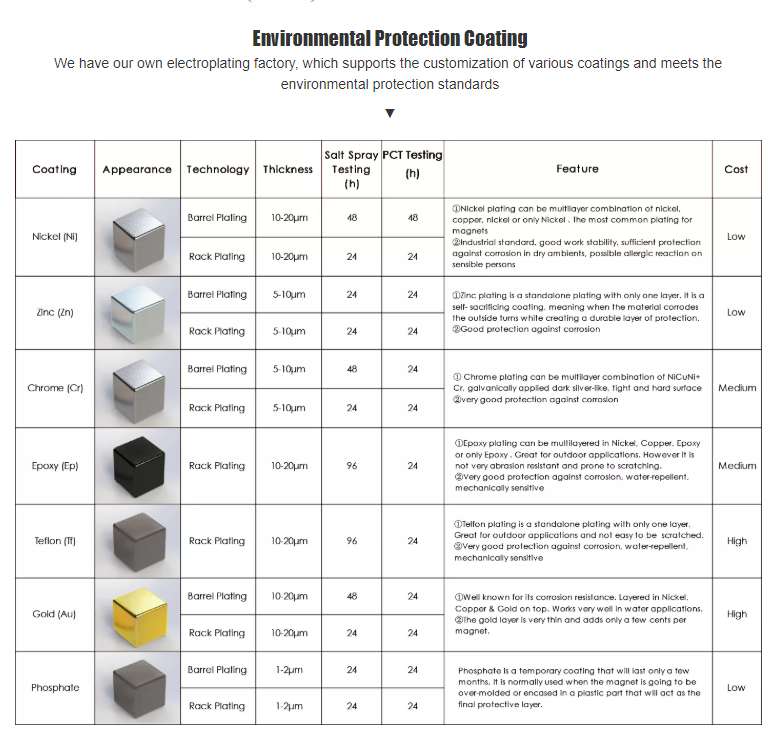

Curatio superficiei:

Magneta permanentia facile oxidantur. Secundum necessitates emptoris, superficies obducetur, resina epoxy obductur, vel galvanoplastica obductur ad corrosionem prohibendam. Nickelam obducendam, galvanizationem, electrophoresin, aliasque operas praebere possumus.

Notae Temperaturae:

Magnetes permanens temperaturae sensibiles sunt. Magnetes permanentes cum resistentia altae temperaturae stricte secundum postulationem emptoris producemus.

Dux consuetus

| Materia | Neodymium-Ferrum-Borum Sinterizatum (NdFeB) | |

| Magnitudo | Consuetudo | |

| Forma | BseraDisc,CcylindrusBar,Riens, C.demersus, SegmentumHetiam,Csursum,TrapezumEgoformae irregulares, etc.. | |

| Perfunctio | N33N54 et cetera. | |

| Tegumentum | Zn, Ni-Cu-Ni, Ni, Aurum, Argentum, Cuprum, Epoxy, Chromium, etc. | |

| Tolerantia magnitudinis | ±0.05mm pro diametro/crassitudine, ±0.1mm pro latitudine/longitudine | |

| Magnetizatio | Crassitudo magnetizata, axialiter magnetizata, diametraliter magnetizata, multipolorum magnetizata, radialiter magnetizata. (Pro requisitis specificis ad personam accommodata magnetizata) | |

| Temperatura Maxima Operativa | Gradus | Temperatura Operativa Maxima |

| N35-N52 | 80°C (176°F) | |

| 33M-48M | 100°C (212°F) | |

| Horae 33-48 | 120°C (248°F) | |

| 30SH-45SH | 150°C (302°F) | |

| 30UH-40UH | 180°C (356°F) | |

| 28EH-38EH | 200°C (392°F) | |

| 28AH-35AH | 220°C (428°F) | |

MOQ et Tempus Ducendi

| Fragmenta | Tempus Ducendi |

| 1000-10000 | decem dies |

| 10000-100000 | Viginti dies |

| 100000-1000000 | Triginta dies |

Quod tibi offerre possumus…

Nos sumus opifices et praebitores professionales magnetum Neodymii in Sinis. Magnetem Neodymii (magnetem NdFeB) secundum necessitates tuas producere possumus.

Efficacia magnetis

Ad magnetis efficaciam determinandam, hi tres parametri praecipue adhibentur:

Remanentia Br: Postquam magnes permanens ad saturationem technicam magnetizatus est et campus magneticus externus sublatus est, Br retentum inductio magnetica residua appellatur.

Vis coactiva Hc: Ad B magnetis permanentis magnetizati ad saturationem technicam ad nihilum reducendum, vis campi magnetici inversi requisita vis coactiva inductionis magneticae, abbreviata vis coactiva, appellatur.

Productum energiae magneticae BH: Densitatem energiae magneticae a magnete in spatio interstitii aerei (spatio inter duos polos magneticos magnetis) constitutam repraesentat, id est, energiam staticam magnetostaticam per unitatem voluminis interstitii aerei. Cum haec energia aequalis sit producto magnetis Bm et Hm, productum energiae magneticae appellatur.

Magneta permanentia cum proprietatibus inter... (vel: ... inter...)N35-N54in foro.

Parametrus Magnetum

| Gradus | Remanentia | Vis Coactiva | Vis Coactiva Intrinseca | Productum Energiae Maximum | Temperatura Operandi | ||||

| Br | Hcb | HCJ | BH maxima | Tw | |||||

| mT | kg | kA/m | kOe | kA/m | kOe | kJ/m³ | MGOe | ||

| N35 | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | XXXIII-XXXVI | 80℃ |

| N38 | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | 80℃ |

| N40 | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥955 | ≥12 | 302-326 | XXXVIII-XLI | 80℃ |

| N42 | 1280-1320 | 12.8-13.2 | ≥923 | ≥11.6 | ≥955 | ≥12 | 318-342 | 40-43 | 80℃ |

| N45 | 1320-1370 | 13.2-13.7 | ≥876 | ≥11.0 | ≥955 | ≥12 | 342-366 | 43-46 | 80℃ |

| N48 | 1370-1420 | 13.7-14.2 | ≥892 | ≥11.2 | ≥955 | ≥12 | 366-390 | 46-49 | 80℃ |

| N50 | 1390-1440 | 13.9-14.4 | ≥836 | ≥10.5 | ≥955 | ≥12 | 374-406 | 47-51 | 80℃ |

| N52 | 1420-1470 | 14.2-14.7 | ≥836 | ≥10.5 | ≥876 | ≥11 | 390-422 | 49-53 | 80℃ |

| N55 | 1460-1520 | 14.6-15.2 | ≥716 | ≥9 | ≥876 | ≥11 | 414-446 | 52-56 | 80℃ |

| XXXV miliones | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | XXXIII-XXXVI | 100℃ |

| XXXVIII miliones | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | 100℃ |

| Quadraginta miliones | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | XXXVIII-XLI | 100℃ |

| 42M | 1280-1320 | 12.8-13.2 | ≥995 | ≥12.0 | ≥1114 | ≥14 | 318-342 | 40-43 | 100℃ |

| 45M | 1320-1370 | 13.2-13.7 | ≥995 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 | 100℃ |

| 48M | 1360-1420 | 13.6-14.2 | ≥1019 | ≥12.8 | ≥1114 | ≥14 | 366-390 | 46-49 | 100℃ |

| 50M | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1114 | ≥14 | 374-406 | 47-51 | 100℃ |

| 52M | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1035 | ≥13 | 390-422 | 49-53 | 100℃ |

| 33H | 1130-1170 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1353 | ≥17 | 247-271 | XXXI-XXXIV | 120℃ |

| 35H | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | XXXIII-XXXVI | 120℃ |

| 38H | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 | 120℃ |

| 40H | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | XXXVIII-XLI | 120℃ |

| 42H | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 318-342 | 40-43 | 120℃ |

| 45H | 1320-1370 | 13.2-13.7 | ≥971 | ≥12.2 | ≥1353 | ≥17 | 342-366 | 43-46 | 120℃ |

| 48H | 1360-1420 | 13.6-14.2 | ≥1027 | ≥12.9 | ≥1353 | ≥17 | 366-390 | 46-49 | 120℃ |

| 50H | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 374-406 | 47-51 | 120℃ |

| 52H | 1420-1470 | 14.2-14.7 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 390-422 | 49-53 | 120℃ |

| 28SH | 1040-1090 | 10.4-10.9 | ≥780 | ≥9.8 | ≥1592 | ≥20 | 207-231 | XXV-XXVIII | 150℃ |

| 30SH | 1080-1130 | 11.3-11.7 | ≥804 | ≥10.1 | ≥1592 | ≥20 | 223-247 | XXVIII-XXXI | 150℃ |

| 33SH | 1130-1170 | 11.3-11.7 | ≥844 | ≥10.6 | ≥1592 | ≥20 | 247-271 | XXXI-XXXIV | 150℃ |

| 35SH | 1170-1220 | 11.7-12.2 | ≥876 | ≥11 | ≥1592 | ≥20 | 263-287 | XXXIII-XXXVI | 150℃ |

| 38SH | 1220-1250 | 12.2-12.5 | ≥907 | ≥10.5 | ≥1592 | ≥20 | 287-310 | 36-39 | 150℃ |

| 40SH | 1250-1280 | 12.5-12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | XXXVIII-XLI | 150℃ |

| 42SH | 1280-1320 | 12.8-13.2 | ≥971 | ≥12.2 | ≥1592 | ≥20 | 318-342 | 40-43 | 150℃ |

| 45SH | 1320-1370 | 13.2-13.7 | ≥979 | ≥12.3 | ≥1592 | ≥20 | 342-366 | 43-46 | 150℃ |

| 50SH | 1390-1440 | 13.9-14.4 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 374-406 | 47-51 | 150℃ |

| 52SH | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 390-422 | 49-53 | 150℃ |

| 28UH | 1020-1080 | 10.2-10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | XXV-XXVIII | CLXXX°C |

| 33UH | 1130-1170 | 11.3-11.7 | ≥812 | ≥10.2 | ≥1990 | ≥25 | 247-271 | XXXI-XXXIV | CLXXX°C |

| 35UH | 1170-1220 | 11.7-12.2 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 263-287 | XXXIII-XXXVI | CLXXX°C |

| 38UH | 1220-1250 | 12.2-12.5 | ≥860 | ≥10.8 | ≥1990 | ≥25 | 287-310 | 36-39 | CLXXX°C |

| 40UH | 1250-1280 | 12.5-12.8 | ≥876 | ≥11.0 | ≥1990 | ≥25 | 302-326 | XXXVIII-XLI | CLXXX°C |

| 42UH | 1270-1320 | 12.7-13.2 | ≥971 | ≥12.2 | ≥1990 | ≥25 | 310-342 | XXXIX-XLIII | CLXXX°C |

| 50UH | 1390-1440 | 13.9-14.4 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 374-406 | 47-51 | CLXXX°C |

| 52UH | 1420-1470 | 14.2-14.7 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 390-422 | 49-53 | CLXXX°C |

| 28EH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | XXV-XXVIII | 200℃ |

| 30EH | 1080-1130 | 11.3-11.7 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-247 | XXVIII-XXXI | 200℃ |

| 33EH | 1130-1170 | 11.3-11.7 | ≥820 | ≥10.3 | ≥2388 | ≥30 | 247-271 | XXXI-XXXIV | 200℃ |

| 35EH | 1170-1220 | 11.7-12.2 | ≥836 | ≥10.5 | ≥2388 | ≥30 | 263-287 | XXXIII-XXXVI | 200℃ |

| XXVIII AH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2706 | ≥34 | 207-231 | XXV-XXVIII | 230℃ |

| 30AH | 1070-1130 | 10.7-11.3 | ≥812 | ≥10.2 | ≥2706 | ≥34 | 215-247 | XXVII-XXXI | 230℃ |

| 33AH | 1110-1170 | 11.1-11.7 | ≥820 | ≥10.3 | ≥2706 | ≥34 | 239-271 | XXX-XXXIV | 230℃ |

Singula involucri