Magnet Neodymium Kustom

Sembrani neodymium khusus miturut syarat perusahaan sampeyan. We ngedol kabeh gelar saka wesi sembrani neodymium, wangun adat, ukuran lan lapisan

Produsen Magnet Neodymium, pabrik ing China

HuizhouTeknologi FullzenCo., Ltd minangka profesionalprodusen magnet neodymium, produsen magnet khusus, pabrik, lan pemasok ing China wiwit taun 2016. Kita spesialis ing eksperimen, desain, teknik, manufaktur, inspeksi, lan perakitan magnet neodymium khusus. Kustomisasi kanggo nyukupi kabutuhan perusahaan sampeyan. Kita nawakake produk sing wis ana uga layanan khusus, desain khusus magnet permanen, magnet neodymium sing bentuke khusus, digawe khusus kanggo industri sampeyan.

Pilih Magnet Neodymium Panjenengan

Video magnet neodymium

Neodymium magnet introduksi

Magnetik neodymium, uga dikenal minangka magnet NdFeB, yaiku kristal sistem kristal Tetragonal sing dibentuk dening Nd2Fe14B. Iku materi Magnetik digawe saka logam praseodymium neodymium liwat preparation lan sintering. Sembrani jinis iki minangka magnet permanen sing sembrani nomer loro mung kanggo sembrani holmium nol Absolute, lan uga magnet Rare-earth sing paling umum digunakake.

Komposisi kimia magnet neodymium

Neodymium wesi boron bahan magnet permanen minangka bahan magnet permanen adhedhasar senyawa intermetallic Nd2Fe14B. Komponen utama yaiku unsur tanah jarang neodymium (Nd), wesi (Fe), lan boron (B). Unsur bumi langka sing utama yaiku neodymium (Nd), sing bisa diganti sebagian karo logam langka liyane kayata dysprosium (Dy) lan praseodymium (Pr) kanggo entuk sifat sing beda. Wesi uga bisa diganti sebagian karo logam liyane kayata kobalt (Co) lan aluminium (Al). Isi boron cilik, nanging nduweni peran penting ing pambentukan senyawa intermetallic struktur kristal tetragonal, nggawe senyawa duwe magnetization jenuh dhuwur, anisotropi uniaxial dhuwur, lan suhu Curie dhuwur.

Aliran proses magnet Neodymium

Aliran proses:batching → leleh lan ingot nggawe / strip mbuwang → bubuk nggawe → ngecor → sintering lan tempering → testing magnetik → grinding Processing → pin cutting processing → electroplating → produk rampung. Bahan kasebut minangka dhasar, lan sintering lan tempering minangka kunci.

Alat produksi lan alat uji kinerja kanggo kosong magnet boron wesi neodymium:kalebu tungku peleburan, tungku lempar strip, mesin penghancur, pabrik aliran udara, mesin cetakan kompresi, mesin kemasan vakum, mesin penet isostatik, tungku sintering, tungku vakum perawatan panas, tester kinerja magnetik, meter Gaussian.

Piranti mesin magnet boron wesi neodymium:penggilingan tanpa pusat, mesin pembulatan, penggilingan ujung ganda, penggilingan datar, mesin pengiris, penggilingan dua sisi, pemotongan kawat, pengeboran bangku, penggilingan tidak teratur, dll.

Aplikasi magnet neodymium

Sintered neodymium wesi boron bahan magnet permanen duwe sifat Magnetik banget lan digunakake digunakake ing kothak kayata electronics, mesin daya, peralatan medical, Toys, packaging, mesin hardware, aerospace, etc. Sing umum kalebu motor magnet permanen, speaker, separator Magnetik, komputer disk drive, Magnetik resonance imaging instruments peralatan, etc.

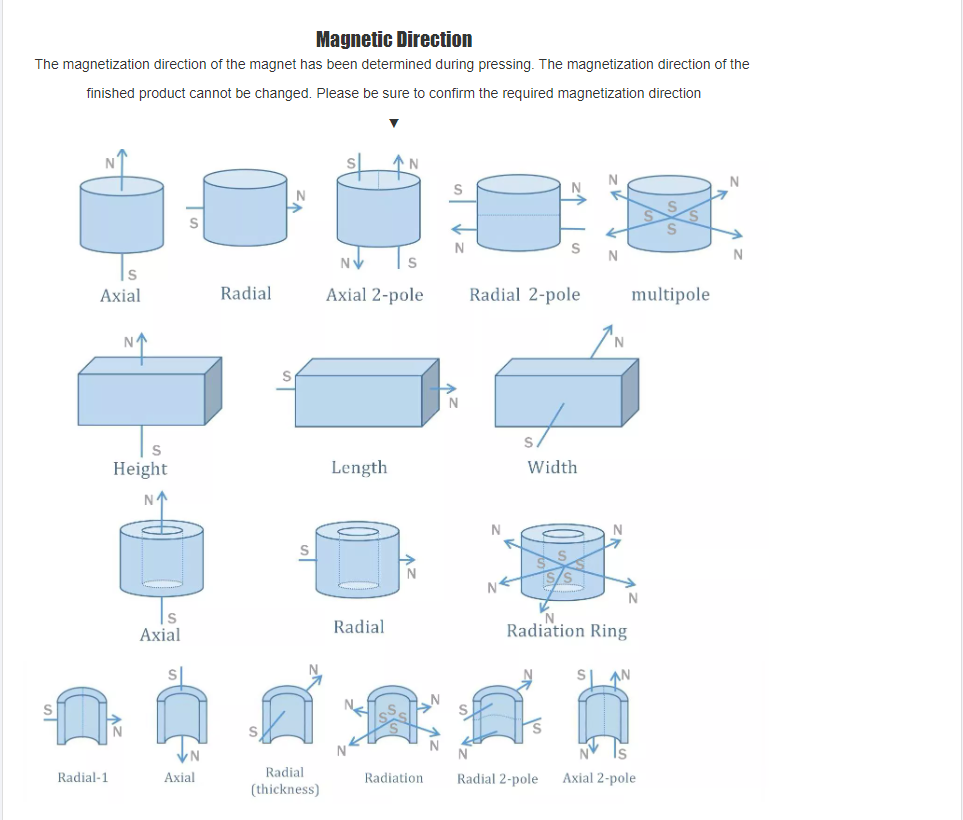

arah magnetisasi magnet Neodymium lanlapisan permukaan

Ora bisa nemokake apa sing sampeyan goleki?

Umume, ana saham magnet neodymium umum utawa bahan mentah ing gudang kita. Nanging yen sampeyan duwe panjaluk khusus, kita uga nyedhiyakake layanan kustomisasi. Kita uga nampa OEM / ODM.

Magnet Neodymium Kustom

HuizhouTeknologi FullzenCo., Ltd minangka produsen magnet profesional.Perusahaan kita magnet bumi langka khusus lan salah sawijining produsen magnet khusus ndhuwur. Kita khusus ing eksperimen, desain, teknik, manufaktur, inspeksi lan perakitanwesi sembrani neodymium adat. Kustomisasi kanggo nyukupi syarat perusahaan sampeyan. Minangka pandhuan khusus ing ngisor iki, kita adol magnet neodymium lengkap. We offer produk mati-the-rak uga layanan selaras, sembrani permanen adat,digawe khusus kanggo industri.Kaya sembrani busur neodymium gedhe selaras kanggo sampeyan.

Ukuran lan wangun:

Kita bisa nyedhiyakake sing disesuaikancakram, silinder, ring, kotak persegi, blok persegi panjang, busur, countersunk, pancing lan magnet permanen sing ora duwe aturan baku.

Pabrikan:

Kita nggunakake otomatisasiperalatankanggo ngethok lan tlatah bahan mentah kanggo nggawe dimensi magnet permanen sing dikarepake, kanthi toleransi mikro, kanggo entuk efek finishing.

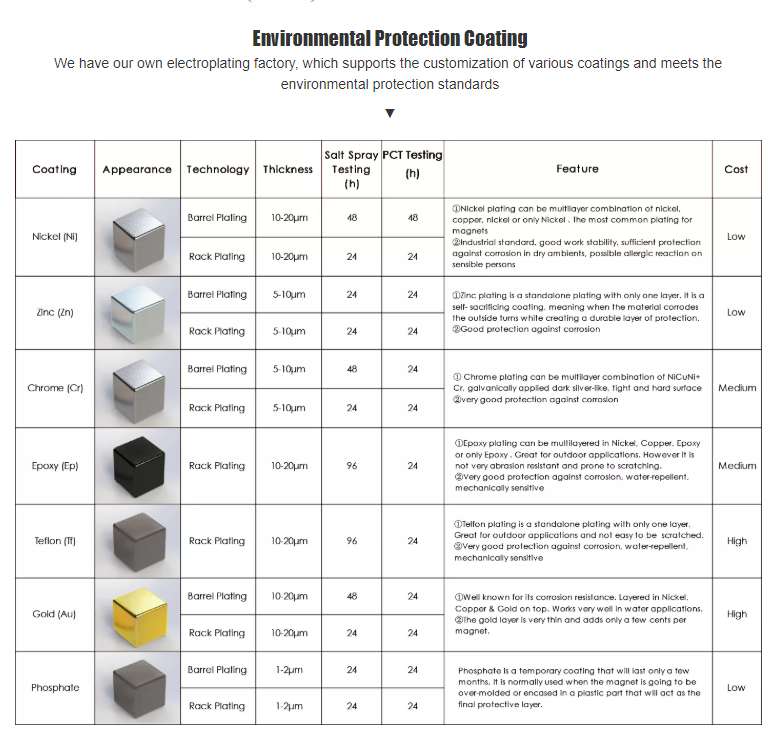

Perawatan permukaan:

Magnet permanen gampang dioksidasi. Miturut kabutuhan pelanggan, lumahing bakal dilapisi, dilapisi epoksi utawa dilapisi kanggo nyegah karat. Kita bisa nyedhiyakake plating nikel, galvanisasi, elektroforesis lan layanan liyane.

Cathetan Suhu:

Magnet permanen sensitif suhu. Kita bakal strictly gawé miturut dikarepake customer kanggo wesi sembrani permanen karo resistance suhu dhuwur.

Pandhuan khusus

| Bahan | Neodymium-Besi-Boron (NdFeB) sing disinter | |

| Ukuran | adat | |

| wangun | Bkunci,Disc,Cylinder,Bar,Ring, Cuntersunk, SegmenHoke,Cmunggah,Trapezoid, akuwangun sing ora teratur, lsp. | |

| Kinerja | N33 N35 N38 N40 N42 N45 N48 N50 N52N54 ugi. | |

| Lapisan | Zn, Ni-Cu-Ni, Ni, Emas, Perak, Tembaga, Epoxy, Chrome, lsp | |

| Toleransi ukuran | ±0,05mm kanggo diameter/ketebalan, ±0,1mm kanggo jembar/dawa | |

| Magnetisasi | Ketebalan Magnetized, Axially Magnetized, Diametrally Magnetized, Multi-kutub magnetized, Radial Magnetized. (Customzied syarat khusus magnetized) | |

| Maks. Suhu Kerja | sasmita | Maks. Suhu operasi |

| N35-N52 | 80°C (176°F) | |

| 33M-48M | 100°C (212°F) | |

| 33H-48H | 120°C (248°F) | |

| 30SH-45SH | 150°C (302°F) | |

| 30UH-40UH | 180°C (356°F) | |

| 28EH-38EH | 200°C (392°F) | |

| 28AH-35AH | 220°C (428°F) | |

MOQ & Lead Time

| Potongan | Lead Time |

| 1000-10000 | 10 dina |

| 10000-100000 | 20 dina |

| 100000-1000000 | 30 dina |

Apa kita bisa menehi sampeyan…

Kita minangka produsen lan pemasok Magnet Neodymium profesional ing China. Kita bisa ngasilake Neodymium Magnet (NdFeB magnet) miturut syarat sampeyan.

kinerja Magnet

Utamane ana telung paramèter kinerja ing ngisor iki kanggo nemtokake kinerja magnet:

Remanence Br: Sawise magnet permanen wis magnetized kanggo kahanan kang gawe jenuh technical lan njaba Magnetik kolom dibusak, ing Br disimpen disebut induksi Magnetik residual.

Gaya Coercive Hc: Kanggo ngurangi B saka magnet permanen magnetized kanggo jenuh technical kanggo nul, kekuatan medan magnet mbalikke dibutuhake disebut pasukan coercive induksi Magnetik, disingkat gaya coercive.

Produk energi Magnetik BH: Iku nuduhake Kapadhetan energi Magnetik ditetepake dening sembrani ing spasi longkangan online (spasi antarane loro kutub Magnetik saka magnet), sing, energi magnetostatic statis saben volume unit saka longkangan online. Amarga energi iki padha karo produk magnet Bm lan Hm, mula diarani produk energi magnetik.

Kita bisa ngatur wesi sembrani permanen karo sifat antaraneN35-N54ing pasar.

Parameter saka Magnet

| sasmita | Remanensi | Kekuwatan Paksa | Kekuwatan Koersif Intrinsik | Produk Energi Maksimum | Temp Kerja | ||||

| Br | Hcb | Hcj | BH maks | Tw | |||||

| mT | KGs | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | ||

| N35 | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 80 ℃ |

| N38 | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | 80 ℃ |

| N40 | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥955 | ≥12 | 302-326 | 38-41 | 80 ℃ |

| N42 | 1280-1320 | 12.8-13.2 | ≥923 | ≥11.6 | ≥955 | ≥12 | 318-342 | 40-43 | 80 ℃ |

| N45 | 1320-1370 | 13.2-13.7 | ≥876 | ≥11.0 | ≥955 | ≥12 | 342-366 | 43-46 | 80 ℃ |

| N48 | 1370-1420 | 13.7-14.2 | ≥892 | ≥11.2 | ≥955 | ≥12 | 366-390 | 46-49 | 80 ℃ |

| N50 | 1390-1440 | 13.9-14.4 | ≥836 | ≥10.5 | ≥955 | ≥12 | 374-406 | 47-51 | 80 ℃ |

| N52 | 1420-1470 | 14.2-14.7 | ≥836 | ≥10.5 | ≥876 | ≥11 | 390-422 | 49-53 | 80 ℃ |

| N55 | 1460-1520 | 14.6-15.2 | ≥716 | ≥9 | ≥876 | ≥11 | 414-446 | 52-56 | 80 ℃ |

| 35M | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 100 ℃ |

| 38M | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | 100 ℃ |

| 40M | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | 100 ℃ |

| 42M | 1280-1320 | 12.8-13.2 | ≥995 | ≥12.0 | ≥1114 | ≥14 | 318-342 | 40-43 | 100 ℃ |

| 45M | 1320-1370 | 13.2-13.7 | ≥995 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 | 100 ℃ |

| 48M | 1360-1420 | 13.6-14.2 | ≥1019 | ≥12.8 | ≥1114 | ≥14 | 366-390 | 46-49 | 100 ℃ |

| 50M | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1114 | ≥14 | 374-406 | 47-51 | 100 ℃ |

| 52M | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1035 | ≥13 | 390-422 | 49-53 | 100 ℃ |

| 33H | 1130-1170 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1353 | ≥17 | 247-271 | 31-34 | 120 ℃ |

| 35H | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 120 ℃ |

| 38H | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 | 120 ℃ |

| 40H | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | 120 ℃ |

| 42H | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 318-342 | 40-43 | 120 ℃ |

| 45H | 1320-1370 | 13.2-13.7 | ≥971 | ≥12.2 | ≥1353 | ≥17 | 342-366 | 43-46 | 120 ℃ |

| 48H | 1360-1420 | 13.6-14.2 | ≥1027 | ≥12.9 | ≥1353 | ≥17 | 366-390 | 46-49 | 120 ℃ |

| 50H | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 374-406 | 47-51 | 120 ℃ |

| 52H | 1420-1470 | 14.2-14.7 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 390-422 | 49-53 | 120 ℃ |

| 28SH | 1040-1090 | 10.4-10.9 | ≥780 | ≥9.8 | ≥1592 | ≥20 | 207-231 | 25-28 | 150 ℃ |

| 30 SH | 1080-1130 | 11.3-11.7 | ≥804 | ≥10.1 | ≥1592 | ≥20 | 223-247 | 28-31 | 150 ℃ |

| 33SH | 1130-1170 | 11.3-11.7 | ≥844 | ≥10.6 | ≥1592 | ≥20 | 247-271 | 31-34 | 150 ℃ |

| 35SH | 1170-1220 | 11.7-12.2 | ≥876 | ≥11 | ≥1592 | ≥20 | 263-287 | 33-36 | 150 ℃ |

| 38SH | 1220-1250 | 12.2-12.5 | ≥907 | ≥10.5 | ≥1592 | ≥20 | 287-310 | 36-39 | 150 ℃ |

| 40SH | 1250-1280 | 12.5-12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 | 150 ℃ |

| 42SH | 1280-1320 | 12.8-13.2 | ≥971 | ≥12.2 | ≥1592 | ≥20 | 318-342 | 40-43 | 150 ℃ |

| 45SH | 1320-1370 | 13.2-13.7 | ≥979 | ≥12.3 | ≥1592 | ≥20 | 342-366 | 43-46 | 150 ℃ |

| 50SH | 1390-1440 | 13.9-14.4 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 374-406 | 47-51 | 150 ℃ |

| 52SH | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 390-422 | 49-53 | 150 ℃ |

| 28UH | 1020-1080 | 10.2-10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | 25-28 | 180 ℃ |

| 33UH | 1130-1170 | 11.3-11.7 | ≥812 | ≥10.2 | ≥1990 | ≥25 | 247-271 | 31-34 | 180 ℃ |

| 35UH | 1170-1220 | 11.7-12.2 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 263-287 | 33-36 | 180 ℃ |

| 38UH | 1220-1250 | 12.2-12.5 | ≥860 | ≥10.8 | ≥1990 | ≥25 | 287-310 | 36-39 | 180 ℃ |

| 40UH | 1250-1280 | 12.5-12.8 | ≥876 | ≥11.0 | ≥1990 | ≥25 | 302-326 | 38-41 | 180 ℃ |

| 42UH | 1270-1320 | 12.7-13.2 | ≥971 | ≥12.2 | ≥1990 | ≥25 | 310-342 | 39-43 | 180 ℃ |

| 50UH | 1390-1440 | 13.9-14.4 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 374-406 | 47-51 | 180 ℃ |

| 52UH | 1420-1470 | 14.2-14.7 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 390-422 | 49-53 | 180 ℃ |

| 28EH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | 25-28 | 200 ℃ |

| 30 EH | 1080-1130 | 11.3-11.7 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-247 | 28-31 | 200 ℃ |

| 33EH | 1130-1170 | 11.3-11.7 | ≥820 | ≥10.3 | ≥2388 | ≥30 | 247-271 | 31-34 | 200 ℃ |

| 35EH | 1170-1220 | 11.7-12.2 | ≥836 | ≥10.5 | ≥2388 | ≥30 | 263-287 | 33-36 | 200 ℃ |

| 28AH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2706 | ≥34 | 207-231 | 25-28 | 230 ℃ |

| 30AH | 1070-1130 | 10.7-11.3 | ≥812 | ≥10.2 | ≥2706 | ≥34 | 215-247 | 27-31 | 230 ℃ |

| 33AH | 1110-1170 | 11.1-11.7 | ≥820 | ≥10.3 | ≥2706 | ≥34 | 239-271 | 30-34 | 230 ℃ |

Rincian kemasan