Magnet Neodymium omenala

Ihe ndọta neodymium omenala dị ka ụlọ ọrụ gị chọrọ. Anyị na-ere akara niile nke neodymium magnetik, ụdị omenala, nha na mkpuchi

Onye nrụpụta Neodymium Magnets, ụlọ ọrụ na China

HuizhouTeknụzụ zuru ezuCo., Ltd bụ ọkachamara na azụmaahịaneodymium magnet emeputa, omenala magnet emeputa , factory, na soplaya na china kemgbe 2016. Anyị na-pụrụ iche na nnwale, imewe, engineering, n'ichepụta, nnyocha, na-ezukọ nke omenala neodymium magnets. Nhazi iji mezuo ihe ụlọ ọrụ gị chọrọ. Anyị na-enye ngwaahịa na-adịghị na shelf yana ọrụ ahaziri ahazi, ihe eji eme ihe ndọta na-adịgide adịgide , magnetik neodymium emebere emebere, akwa akwa maka ụlọ ọrụ gị.

Họrọ Magnet Neodymium Gị

Neodymium magnetik vidiyo

Neodymium ihe ndọta

Neodymium magnetik, nke a makwaara dị ka ndọta NdFeB, bụ sistemu kristal Tetragonal nke Nd2Fe14B mebere. Ọ bụ ihe ndọta emere site na metal praseodymium neodymium site na nkwadebe na ịgbakọ. Ụdị ndọta a bụ magnet na-adịgide adịgide nke magnetism ya bụ nke abụọ na-enweghị ihe ndọta holmium zuru oke, ma ọ bụkwa ihe ndọta na-adịghị ahụkebe nke a na-ejikarị eme ihe.

Ihe mejupụtara kemịkalụ neodymium magnetik

Neodymium iron boron ihe ndọta na-adịgide adịgide bụ ihe ndọta na-adịgide adịgide dabere na ngwakọta intermetallic Nd2Fe14B. Ihe mejupụtara ya bụ ihe ndị na-adịghị ahụkebe ụwa neodymium (Nd), iron (Fe), na boron (B). Isi ihe na-adịghị ahụkebe ụwa bụ neodymium (Nd), nke nwere ike dochie ya na ọla ndị ọzọ na-adịghị ahụkebe dị ka dysprosium (Dy) na praseodymium (Pr) iji nweta ihe dị iche iche. Enwere ike iji ọla ndị ọzọ dị ka cobalt (Co) na aluminom (Al) dochie ya nke ọma. Ọdịnaya boron dị ntakịrị, mana ọ na-arụ ọrụ dị mkpa n'ịmepụta ihe owuwu kristal tetragonal intermetallic ogige, na-eme ka ogige ndị ahụ nwee nnukwu saturation magnetization, elu uniaxial anisotropy, na oke Curie okpomọkụ.

Neodymium magnetik usoro eruba

Usoro usoro:batching → agbaze na ingot ime / mgbapụ ịtụba → ntụ ntụ ime → ịkpụzi → sintering na tempering → magnetik ule → egweri nhazi → pin ịkpụ nhazi → electroplating → okokụre ngwaahịa. Efrata bụ ntọala, na sintering na tempering bụ isi ihe.

Ngwa mmepụta na ngwaọrụ nnwale arụmọrụ maka neodymium iron boron magnet oghere:gụnyere ọkụ na-agbaze, ọkụ na-atụpụ ihe, igwe na-etipịa ihe, igwe igwe ikuku, igwe na-akpụzi mkpakọ, igwe nkwakọba ihe, igwe mgbasa ozi isostatic, ite ọkụ, ọkụ na-ekpo ọkụ ọkụ, ihe nleba anya magnetik, mita Gaussian.

Ngwá ọrụ igwe magnetik boron nke Neodymium iron:igwe anaghị agba nchara, igwe na-agbagharị agbagharị, igwe na-egweri ngwụcha okpukpu abụọ, igwe na-egweri ewepụghị, igwe slicing, igwe akụkụ abụọ, ịcha waya, mgbanaka bench, egweri oge niile, wdg.

Ngwa Neodymium magnetik

Ihe ndọta ígwè boron na-adịgide adịgide nke sintered neodymium nwere ezigbo ihe ndọta ma a na-ejikarị ya eme ihe n'ọhịa dịka eletrọniki, igwe ike, akụrụngwa ahụike, ihe egwuregwu, nkwakọ ngwaahịa, igwe ngwaike, ụgbọelu, wdg. Ndị a na-ahụkarị gụnyere injin magnet na-adịgide adịgide, ndị na-ekwu okwu, ndị na-ekewapụ magnet, draịva diski kọmputa, ngwa ngwaọrụ onyonyo magnet, wdg.

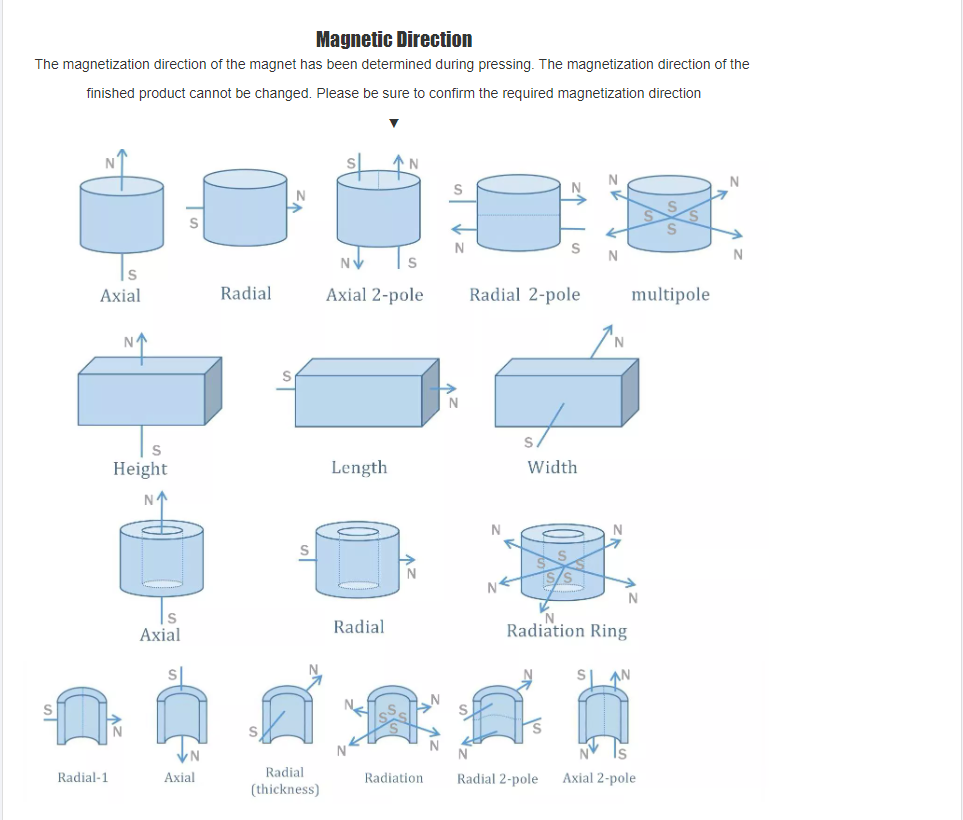

Neodymium magnets magnetization direction namkpuchi elu

Enweghị ike ịchọta ihe ị na-achọ?

Na mkpokọta, enwere nnukwu ihe ndọta neodymium ma ọ bụ akụrụngwa n'ụlọ nkwakọba ihe anyị. Mana ọ bụrụ na ị nwere ọchịchọ pụrụ iche, anyị na-enyekwa ọrụ nhazi nhazi. Anyị na-anabata OEM/ODM.

Magnet Neodymium omenala

HuizhouTeknụzụ zuru ezuCo., Ltd bụ ọkachamara magnet manufacturer.Our ụlọ ọrụ omenala obere ụwa magnets na otu n'ime n'elu omenala magnet emepụta.We na-pụrụ iche na nnwale, imewe, engineering, n'ichepụta, nnyocha na-ezukọ nkeihe ndọta neodymium omenala. Nhazi iji mezuo ihe ụlọ ọrụ gị chọrọ. Dị ka ntuziaka omenala na-egosi, anyị na-ere magnetik neodymium zuru oke. Anyị na-enye ngwaahịa na-anọghị na shelf yana ọrụ ahaziri ahazi, ndọta na-adịgide adịgide, akwa akwa emere maka ụlọ ọrụ gị. Dị ka nnukwu neodymium arc magnet ahaziri maka gị.

Nha na ọdịdị:

Anyị nwere ike ịnye ahaziridiski, silinda, mgbaaka, square cube, akụkụ anọ ngọngọ, arc, countersunk, nko na ndị ọzọ na-adịghị adịgide adịgide magnetik.

Mepụta:

Anyị na-eji akpaakaakụrụngwaiji bee ma gwerie ihe eji eme ihe iji mee ka akụkụ nke magnet na-adịgide adịgide ịchọrọ, na obere ndidi, iji nweta mmetụta njedebe.

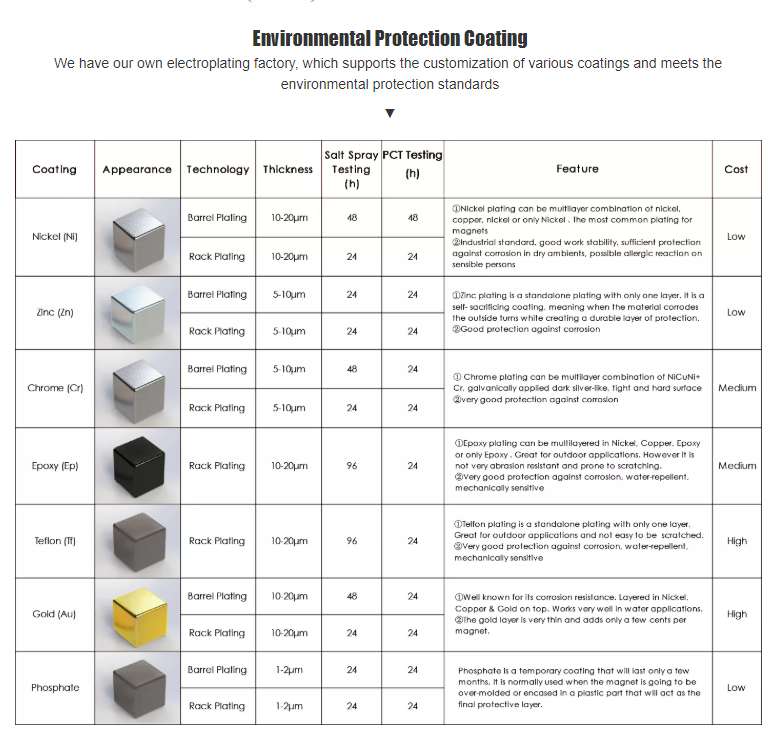

Ọgwụgwọ elu:

Ihe ndọta na-adịgide adịgide dị mfe ka ọ bụrụ oxidized. Dị ka mkpa ndị ahịa si dị, a ga-ekpuchi elu ahụ, mkpuchi epoxy ma ọ bụ electroplated iji gbochie mmebi. Anyị nwere ike inye nickel plating, galvanization, electrophoresis na ọrụ ndị ọzọ.

Ihe ndetu okpomọkụ:

Igwe ndọta na-adịgide adịgide na-enwe mmetụta okpomọkụ. Anyị ga-emepụta nke ọma dị ka ọchịchọ ndị ahịa chọrọ maka magnet na-adịgide adịgide na-eguzogide okpomọkụ dị elu.

Ntuziaka omenala

| Ihe onwunwe | Neodymium-Iron-Boron Sintered (NdFeB) | |

| Nha | Omenala | |

| Ụdị | Bigbachi,Disc,Cylinder,Ba,Ring, Cọnọdụ, AkụkụHoooo,Celu,Trazoid, Iudi oge nile, wdg. | |

| Arụmọrụ | N33 N35 N38 N40 N42 N45 N48 N50 N52N54 wdg. | |

| Mkpuchi | Zn, Ni-Cu-Ni, Ni, Gold, Silver, Copper, Epoxy, Chrome, wdg | |

| Nkwenye nha | ± 0.05mm maka diamater / ọkpụrụkpụ, ± 0.1mm maka obosara / ogologo | |

| Magnetization | Ọkpụrụkpụ nke magnet, nke magnet n'akụkụ ya, nke magnet n'akụkụ ya, nke magnet n'ọtụtụ ogidi, nke magnet n'akụkụ ya. (A na-eme magnet n'ụzọ pụrụ iche ahaziri iche) | |

| Oke. Okpomọkụ na-arụ ọrụ | Ọkwa | Oke. Okpomọkụ na-arụ ọrụ |

| N35-N52 | 80°C (176°F) | |

| 33M-48M | 100°C (212°F) | |

| 33H-48H | 120°C (248°F) | |

| 30SH-45SH | 150°C (302°F) | |

| 30UH-40UH | 180°C (356°F) | |

| 28EH-38EH | 200°C (392°F) | |

| 28AH-35AH | 220°C (428°F) | |

MOQ & Oge ndu

| Iberibe | Etiti oge |

| 1000-10000 | Ụbọchị 10 |

| 10000-100000 | Ụbọchị 20 |

| 100000-1000000 | Ụbọchị 30 |

Ihe anyị nwere ike inye gị…

Anyị bụ ndị ọkachamara Neodymium Magnet na-emepụta na ndị na-ebubata ya na China. Anyị nwere ike ịmepụta Neodymium Magnet (NdFeB magnet) dịka ihe ị chọrọ.

Ịrụ ọrụ magnet

Enwere oke arụmọrụ atọ ndị a iji chọpụta arụmọrụ magnet:

Remanence Br: Mgbe magnet na-adịgide adịgide ka ọ bụrụ saturation teknụzụ ma wepụ mpaghara magnet mpụga, a na-akpọ Br nke ejidere residual magnetic induction.

Ike mmanye Hc: Iji wedata B nke magnet na-adịgide adịgide magnetized na saturation teknụzụ ka ọ bụrụ efu, ike ndọta ntụgharị achọrọ ka a na-akpọ ike induction mmanye magnetik, nke akpọchiri dị ka ike mmanye.

Ngwaahịa ike ndọta BH: Ọ na-anọchi anya njupụta ike magnetik guzobe na oghere ikuku (ohere dị n'etiti ogwe magnetik abụọ nke magnet), ya bụ, ike magnetostatic static kwa otu olu nke oghere ikuku. Ebe ọ bụ na ike a hà nhata ngwaahịa nke magnet Bm na Hm, a na-akpọ ya ngwaahịa ike magnetik.

Anyị nwere ike hazie ndọta na-adịgide adịgide nwere njirimara n'etitiN35-N54n'ahịa.

Parameter nke Igwe Ọdụdọ

| Ọkwa | Ịnọgide | Ike mmanye | Ike mmanye n'ime ime | Ngwaahịa ike kacha | Okpomọkụ na-arụ ọrụ | ||||

| Br | Hcb | Hcj | Ọnụ ego BH kachasị | Tw | |||||

| mT | Ndị KG | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | ||

| N35 | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 80 ℃ |

| N38 | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | 80 ℃ |

| N40 | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥955 | ≥12 | 302-326 | 38-41 | 80 ℃ |

| N42 | 1280-1320 | 12.8-13.2 | ≥923 | ≥11.6 | ≥955 | ≥12 | 318-342 | 40-43 | 80 ℃ |

| N45 | 1320-1370 | 13.2-13.7 | ≥876 | ≥11.0 | ≥955 | ≥12 | 342-366 | 43-46 | 80 ℃ |

| N48 | 1370-1420 | 13.7-14.2 | ≥892 | ≥11.2 | ≥955 | ≥12 | 366-390 | 46-49 | 80 ℃ |

| N50 | 1390-1440 | 13.9-14.4 | ≥836 | ≥10.5 | ≥955 | ≥12 | 374-406 | 47-51 | 80 ℃ |

| N52 | 1420-1470 | 14.2-14.7 | ≥836 | ≥10.5 | ≥876 | ≥11 | 390-422 | 49-53 | 80 ℃ |

| N55 | 1460-1520 | 14.6-15.2 | ≥716 | ≥9 | ≥876 | ≥11 | 414-446 | 52-56 | 80 ℃ |

| 35M | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 100 ℃ |

| 38M | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | 100 ℃ |

| 40M | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | 100 ℃ |

| 42M | 1280-1320 | 12.8-13.2 | ≥995 | ≥12.0 | ≥1114 | ≥14 | 318-342 | 40-43 | 100 ℃ |

| 45M | 1320-1370 | 13.2-13.7 | ≥995 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 | 100 ℃ |

| 48M | 1360-1420 | 13.6-14.2 | ≥1019 | ≥12.8 | ≥1114 | ≥14 | 366-390 | 46-49 | 100 ℃ |

| 50M | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1114 | ≥14 | 374-406 | 47-51 | 100 ℃ |

| 52M | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1035 | ≥13 | 390-422 | 49-53 | 100 ℃ |

| 33H | 1130-1170 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1353 | ≥17 | 247-271 | 31-34 | 120 ℃ |

| 35H | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 120 ℃ |

| 38H | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 | 120 ℃ |

| 40H | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | 120 ℃ |

| 42H | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 318-342 | 40-43 | 120 ℃ |

| 45H | 1320-1370 | 13.2-13.7 | ≥971 | ≥12.2 | ≥1353 | ≥17 | 342-366 | 43-46 | 120 ℃ |

| 48H | 1360-1420 | 13.6-14.2 | ≥1027 | ≥12.9 | ≥1353 | ≥17 | 366-390 | 46-49 | 120 ℃ |

| 50H | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 374-406 | 47-51 | 120 ℃ |

| 52H | 1420-1470 | 14.2-14.7 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 390-422 | 49-53 | 120 ℃ |

| 28SH | 1040-1090 | 10.4-10.9 | ≥780 | ≥9.8 | ≥1592 | ≥20 | 207-231 | 25-28 | 150℃ |

| 30SH | 1080-1130 | 11.3-11.7 | ≥804 | ≥10.1 | ≥1592 | ≥20 | 223-247 | 28-31 | 150℃ |

| 33SH | 1130-1170 | 11.3-11.7 | ≥844 | ≥10.6 | ≥1592 | ≥20 | 247-271 | 31-34 | 150℃ |

| 35SH | 1170-1220 | 11.7-12.2 | ≥876 | ≥11 | ≥1592 | ≥20 | 263-287 | 33-36 | 150℃ |

| 38SH | 1220-1250 | 12.2-12.5 | ≥907 | ≥10.5 | ≥1592 | ≥20 | 287-310 | 36-39 | 150℃ |

| 40SH | 1250-1280 | 12.5-12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 | 150℃ |

| 42SH | 1280-1320 | 12.8-13.2 | ≥971 | ≥12.2 | ≥1592 | ≥20 | 318-342 | 40-43 | 150℃ |

| 45SH | 1320-1370 | 13.2-13.7 | ≥979 | ≥12.3 | ≥1592 | ≥20 | 342-366 | 43-46 | 150℃ |

| 50SH | 1390-1440 | 13.9-14.4 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 374-406 | 47-51 | 150℃ |

| 52SH | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 390-422 | 49-53 | 150℃ |

| 28 UH | 1020-1080 | 10.2-10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | 25-28 | 180 ℃ |

| 33 UH | 1130-1170 | 11.3-11.7 | ≥812 | ≥10.2 | ≥1990 | ≥25 | 247-271 | 31-34 | 180 ℃ |

| 35UH | 1170-1220 | 11.7-12.2 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 263-287 | 33-36 | 180 ℃ |

| 38 UH | 1220-1250 | 12.2-12.5 | ≥860 | ≥10.8 | ≥1990 | ≥25 | 287-310 | 36-39 | 180 ℃ |

| 40UH | 1250-1280 | 12.5-12.8 | ≥876 | ≥11.0 | ≥1990 | ≥25 | 302-326 | 38-41 | 180 ℃ |

| 42UH | 1270-1320 | 12.7-13.2 | ≥971 | ≥12.2 | ≥1990 | ≥25 | 310-342 | 39-43 | 180 ℃ |

| 50UH | 1390-1440 | 13.9-14.4 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 374-406 | 47-51 | 180 ℃ |

| 52UH | 1420-1470 | 14.2-14.7 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 390-422 | 49-53 | 180 ℃ |

| 28 EH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | 25-28 | 200 ℃ |

| 30 EH | 1080-1130 | 11.3-11.7 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-247 | 28-31 | 200 ℃ |

| 33 EH | 1130-1170 | 11.3-11.7 | ≥820 | ≥10.3 | ≥2388 | ≥30 | 247-271 | 31-34 | 200 ℃ |

| 35 EH | 1170-1220 | 11.7-12.2 | ≥836 | ≥10.5 | ≥2388 | ≥30 | 263-287 | 33-36 | 200 ℃ |

| 28AH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2706 | ≥34 | 207-231 | 25-28 | 230 ℃ |

| 30AH | 1070-1130 | 10.7-11.3 | ≥812 | ≥10.2 | ≥2706 | ≥34 | 215-247 | 27-31 | 230 ℃ |

| 33AH | 1110-1170 | 11.1-11.7 | ≥820 | ≥10.3 | ≥2706 | ≥34 | 239-271 | 30-34 | 230 ℃ |

Nkọwa nkwakọ ngwaahịa