Leman Neyodim koutim

Leman neyodim koutim selon bezwen konpayi ou an. Nou vann tout kalite leman neyodim, fòm koutim, gwosè ak kouch.

Manifakti Leman Neyodim, faktori nan Lachin

HuizhouTeknoloji FullzenCo., Ltd se yon pwofesyonèlmanifakti leman neodim, manifakti leman koutim, faktori, ak founisè nan Lachin depi 2016. Nou espesyalize nan eksperyans, konsepsyon, jeni, fabrikasyon, enspeksyon, ak asanblaj leman neyodim koutim. Pèsonalizasyon pou satisfè bezwen konpayi ou an. Nou ofri pwodwi ki deja pare ansanm ak sèvis Customized, konsepsyon koutim nan leman pèmanan, leman neyodim ki gen fòm koutim, fèt espesyalman pou endistri ou an.

Chwazi leman Neyodim ou yo

Videyo sou leman Neyodim

Entwodiksyon leman Neyodim

Leman Neyodim, ke yo rele tou leman NdFeB, se yon kristal sistèm tetragonal ki fòme pa Nd2Fe14B. Li se yon materyèl mayetik ki fèt ak metal praseodim neyodim atravè preparasyon ak sinterizasyon. Kalite leman sa a se yon leman pèmanan ki gen yon mayetis ki dezyèm sèlman apre leman olmium zewo absoli, epi li se tou leman latè ra ki pi souvan itilize a.

Konpozisyon chimik leman Neyodim

Materyèl leman pèmanan Neyodim fè bor se yon materyèl leman pèmanan ki baze sou konpoze entèmetalik Nd2Fe14B la. Konpozan prensipal yo se eleman latè ra: Neyodim (Nd), fè (Fe), ak bor (B). Prensipal eleman latè ra a se Neyodim (Nd), ki ka ranplase pasyèlman pa lòt metal latè ra tankou Disprosiòm (Dy) ak Praseodim (Pr) pou jwenn diferan pwopriyete. Fè kapab tou ranplase pasyèlman pa lòt metal tankou Kobalt (Co) ak aliminyòm (Al). Kontni bor la piti, men li jwe yon wòl enpòtan nan fòmasyon konpoze entèmetalik ak estrikti kristal tetragonal, sa ki fè konpoze yo gen yon mayetizasyon saturation ki wo, yon anizotropi uniaxial ki wo, ak yon tanperati Curie ki wo.

Pwosesis koule leman Neyodim

Koule pwosesis la:pwosesis pakèt → fizyon ak fabrikasyon lengote/pwodiksyon bann → fabrikasyon poud → bòdi → sinterizasyon ak tanperaj → tès mayetik → pwosesis fanm → pwosesis koupe peny → galvanoplasti → pwodwi fini. Engredyan yo se fondasyon an, epi sinterizasyon ak tanperaj se kle a.

Zouti pwodiksyon ak zouti tès pèfòmans pou blank leman neyodim fè bor:ki gen ladan founo k ap fonn, founo pou voye bann, machin kraze, moulen koule lè, machin bòdi konpresyon, machin anbalaj vakyòm, machin pou laprès izostatik, founo sinterizasyon, founo vakyòm tretman chalè, tèsteur pèfòmans mayetik, mèt Gaussyen.

Zouti pou machinasyon leman Neyodim fè bor:fanm san sant, machin awondi, fanm doub bout, fanm plat, machin tranche, fanm doub bò, koupe fil, egzèsis ban, fanm iregilye, elatriye.

Aplikasyon pou leman Neyodim

Materyèl leman pèmanan neodim fè bor sinterize yo gen ekselan pwopriyete mayetik epi yo lajman itilize nan domèn tankou elektwonik, machin pouvwa, ekipman medikal, jwèt, anbalaj, machin pyès ki nan konpitè, ayewospasyal, elatriye. Pami yo ki pi komen yo gen motè leman pèmanan, oratè, separateur mayetik, lektè disk òdinatè, enstriman ekipman imaj rezonans mayetik, elatriye.

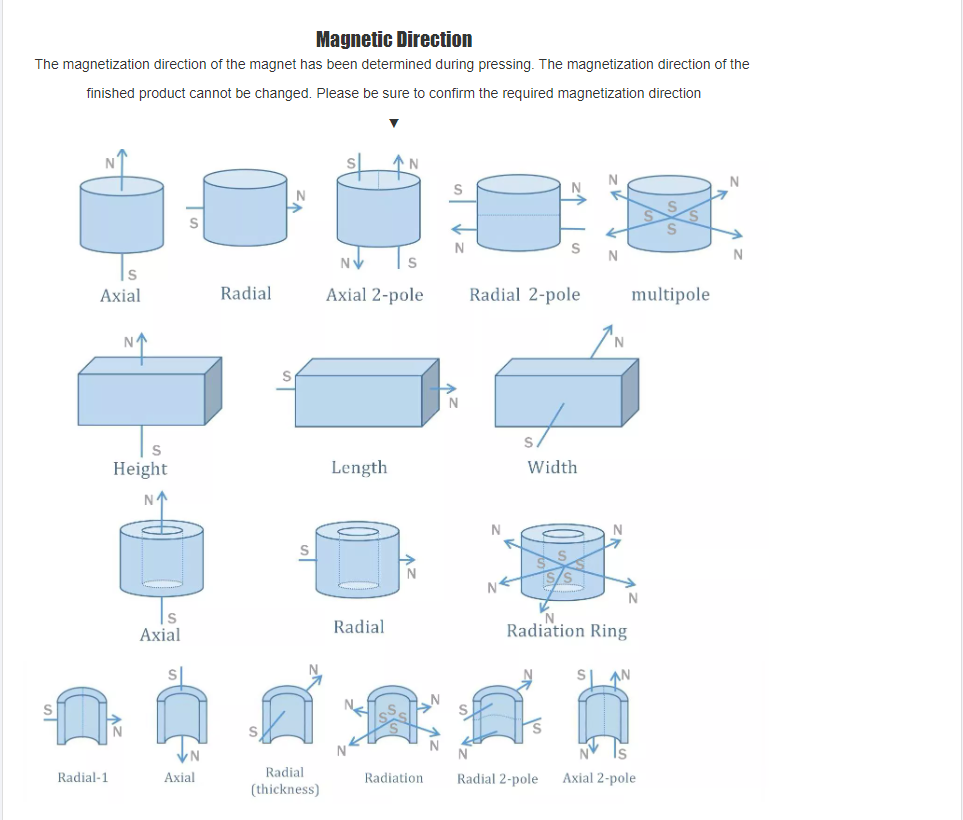

Direksyon mayetizasyon leman Neyodim akkouch sifas

Ou pa t jwenn sa w ap chèche a?

Anjeneral, gen leman neyodim komen oswa matyè premyè nan depo nou an. Men, si ou gen yon demann espesyal, nou ofri tou sèvis personnalisation. Nou aksepte OEM/ODM tou.

Leman Neyodim koutim

HuizhouTeknoloji FullzenCo., Ltd se yon manifakti leman pwofesyonèl. Konpayi nou an fè leman latè ra koutim epi li se youn nan pi gwo manifaktirè leman koutim yo. Nou espesyalize nan eksperyans, konsepsyon, jeni, fabrikasyon, enspeksyon ak asanblajleman neodim koutim. Pèsonalizasyon pou satisfè bezwen konpayi ou an. Jan gid pèsonalizasyon sa a montre, nou vann leman neyodim konplè. Nou ofri pwodwi ki deja disponib ansanm ak sèvis pèsonalize, leman pèmanan pèsonalize, ki fèt espesyalman pou endistri ou an. Tankou gwo leman ak ark neyodim ki pèsonalize pou ou.

Gwosè ak fòm:

Nou ka bay sèvis Customizeddisk, silenn, bag, kib kare, blòk rektangilè, ak, kontre, zen ak lòt leman pèmanan iregilye.

Fabrikasyon:

Nou itilize automatisationekipman yopou koupe epi moulen matyè premyè yo pou fè dimansyon leman pèmanan ou vle a, avèk mikwo tolerans, pou reyalize efè fini an.

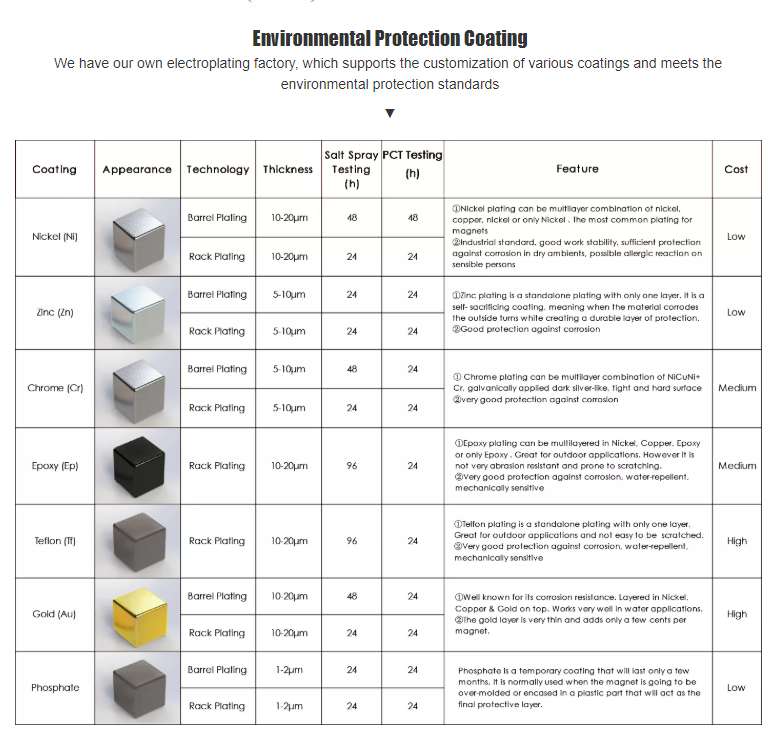

Tretman sifas:

Leman pèmanan yo fasil pou okside. Selon bezwen kliyan an, sifas la pral kouvri, kouvri ak epoksi oswa galvanize pou anpeche korozyon. Nou ka bay nikèl plake, galvanizasyon, elektwoforèz ak lòt sèvis.

Nòt sou Tanperati:

Leman pèmanan sansib a tanperati. Nou pral pwodui leman pèmanan ki reziste tanperati ki wo selon demann kliyan an.

Gid pèsonalize

| Materyèl | Neyodim-fè-bor sinterize (NdFeB) | |

| Gwosè | Personnalisé | |

| Fòm | Bfèmen,Disc,Csilenn,Bar,Ring, Ckontrefone, SegmanHtou,Cleve,Trapez, Mwenfòm iregilye, elatriye. | |

| Pèfòmans | N33 N35 N38 N40 N42 N45 N48 N50 N52N54 elatriye. | |

| Kouch | Zn, Ni-Cu-Ni, Ni, lò, ajan, kwiv, epoksi, chrome, elatriye | |

| Tolerans gwosè | ±0.05mm pou dyamèt/epesè, ±0.1mm pou lajè/longè | |

| Mayetizasyon | Epesè mayetize, Aksyèlman mayetize, Dyametralman mayetize, Plizyè pòl mayetize, Radyalman mayetize. (Selon egzijans espesifik mayetize) | |

| Tanperati maksimòm k ap travay | Klas | Tanperati Operasyon Maksimòm |

| N35-N52 | 80°C (176°F) | |

| 33M- 48M | 100°C (212°F) | |

| 33è-48è | 120°C (248°F) | |

| 30SH-45SH | 150°C (302°F) | |

| 30UH-40UH | 180°C (356°F) | |

| 28EH-38EH | 200°C (392°F) | |

| 28AH-35AH | 220°C (428°F) | |

MOQ & Tan Plon

| Moso | Tan plon |

| 1000-10000 | 10 jou |

| 10000-100000 | 20 jou |

| 100000-1000000 | 30 jou |

Sa nou ka ofri ou…

Nou se yon manifakti ak founisè pwofesyonèl nan leman Neyodim nan Lachin. Nou ka pwodui leman Neyodim (leman NdFeB) selon bezwen ou yo.

Pèfòmans leman

Gen twa prensipal paramèt pèfòmans sa yo pou detèmine pèfòmans leman an:

Br Remanans: Apre yo fin mayetize leman pèmanan an rive nan saturation teknik epi yo retire chan mayetik ekstèn lan, Br ki rete a rele endiksyon mayetik rezidyèl.

Fòs koèsif Hc: Pou diminye B leman pèmanan ki mayetize a nan saturation teknik a zewo, fòs chan mayetik envès ki nesesè a rele fòs koèsif endiksyon mayetik, abreje kòm fòs koèsif.

Pwodui enèji mayetik BH: Li reprezante dansite enèji mayetik leman an etabli nan espas lè a (espas ki genyen ant de pòl mayetik leman an), sa vle di, enèji mayetostatik estatik pou chak inite volim espas lè a. Piske enèji sa a egal a pwodui Bm ak Hm leman an, yo rele li pwodui enèji mayetik.

Nou ka pèsonalize leman pèmanan ak pwopriyete antN35-N54sou mache a.

Paramèt Leman yo

| Klas | Remanans | Fòs Koèsif | Fòs Koèsif Entrinsèk | Pwodwi Enèji Maksimòm | Tanperati Travay | ||||

| Br | Hcb | Hcj | BH maksimòm | Tw | |||||

| mT | KG | kA/m | kOe | kA/m | kOe | kJ/m3 | MGOe | ||

| N35 | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 80℃ |

| N38 | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | 80℃ |

| N40 | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥955 | ≥12 | 302-326 | 38-41 | 80℃ |

| N42 | 1280-1320 | 12.8-13.2 | ≥923 | ≥11.6 | ≥955 | ≥12 | 318-342 | 40-43 | 80℃ |

| N45 | 1320-1370 | 13.2-13.7 | ≥876 | ≥11.0 | ≥955 | ≥12 | 342-366 | 43-46 | 80℃ |

| N48 | 1370-1420 | 13.7-14.2 | ≥892 | ≥11.2 | ≥955 | ≥12 | 366-390 | 46-49 | 80℃ |

| N50 | 1390-1440 | 13.9-14.4 | ≥836 | ≥10.5 | ≥955 | ≥12 | 374-406 | 47-51 | 80℃ |

| N52 | 1420-1470 | 14.2-14.7 | ≥836 | ≥10.5 | ≥876 | ≥11 | 390-422 | 49-53 | 80℃ |

| N55 | 1460-1520 | 14.6-15.2 | ≥716 | ≥9 | ≥876 | ≥11 | 414-446 | 52-56 | 80℃ |

| 35 milyon | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 100℃ |

| 38 milyon | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | 100℃ |

| 40 milyon | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | 100℃ |

| 42 milyon | 1280-1320 | 12.8-13.2 | ≥995 | ≥12.0 | ≥1114 | ≥14 | 318-342 | 40-43 | 100℃ |

| 45 milyon | 1320-1370 | 13.2-13.7 | ≥995 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 | 100℃ |

| 48 milyon | 1360-1420 | 13.6-14.2 | ≥1019 | ≥12.8 | ≥1114 | ≥14 | 366-390 | 46-49 | 100℃ |

| 50 milyon | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1114 | ≥14 | 374-406 | 47-51 | 100℃ |

| 52 milyon | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1035 | ≥13 | 390-422 | 49-53 | 100℃ |

| 33H | 1130-1170 | 11.3-11.7 | ≥836 | ≥10.5 | ≥1353 | ≥17 | 247-271 | 31-34 | 120℃ |

| 35 èdtan | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 120℃ |

| 38 èdtan | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 | 120℃ |

| 40 èdtan | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | 120℃ |

| 42 èdtan | 1280-1320 | 12.8-13.2 | ≥955 | ≥12.0 | ≥1353 | ≥17 | 318-342 | 40-43 | 120℃ |

| 45 èdtan | 1320-1370 | 13.2-13.7 | ≥971 | ≥12.2 | ≥1353 | ≥17 | 342-366 | 43-46 | 120℃ |

| 48 èdtan | 1360-1420 | 13.6-14.2 | ≥1027 | ≥12.9 | ≥1353 | ≥17 | 366-390 | 46-49 | 120℃ |

| 50 èdtan | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 374-406 | 47-51 | 120℃ |

| 52H | 1420-1470 | 14.2-14.7 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 390-422 | 49-53 | 120℃ |

| 28SH | 1040-1090 | 10.4-10.9 | ≥780 | ≥9.8 | ≥1592 | ≥20 | 207-231 | 25-28 | 150 ℃ |

| 30SH | 1080-1130 | 11.3-11.7 | ≥804 | ≥10.1 | ≥1592 | ≥20 | 223-247 | 28-31 | 150 ℃ |

| 33SH | 1130-1170 | 11.3-11.7 | ≥844 | ≥10.6 | ≥1592 | ≥20 | 247-271 | 31-34 | 150 ℃ |

| 35SH | 1170-1220 | 11.7-12.2 | ≥876 | ≥11 | ≥1592 | ≥20 | 263-287 | 33-36 | 150 ℃ |

| 38SH | 1220-1250 | 12.2-12.5 | ≥907 | ≥10.5 | ≥1592 | ≥20 | 287-310 | 36-39 | 150 ℃ |

| 40SH | 1250-1280 | 12.5-12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 | 150 ℃ |

| 42SH | 1280-1320 | 12.8-13.2 | ≥971 | ≥12.2 | ≥1592 | ≥20 | 318-342 | 40-43 | 150 ℃ |

| 45SH | 1320-1370 | 13.2-13.7 | ≥979 | ≥12.3 | ≥1592 | ≥20 | 342-366 | 43-46 | 150 ℃ |

| 50SH | 1390-1440 | 13.9-14.4 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 374-406 | 47-51 | 150 ℃ |

| 52SH | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 390-422 | 49-53 | 150 ℃ |

| 28UH | 1020-1080 | 10.2-10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | 25-28 | 180 ℃ |

| 33UH | 1130-1170 | 11.3-11.7 | ≥812 | ≥10.2 | ≥1990 | ≥25 | 247-271 | 31-34 | 180 ℃ |

| 35UH | 1170-1220 | 11.7-12.2 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 263-287 | 33-36 | 180 ℃ |

| 38UH | 1220-1250 | 12.2-12.5 | ≥860 | ≥10.8 | ≥1990 | ≥25 | 287-310 | 36-39 | 180 ℃ |

| 40UH | 1250-1280 | 12.5-12.8 | ≥876 | ≥11.0 | ≥1990 | ≥25 | 302-326 | 38-41 | 180 ℃ |

| 42UH | 1270-1320 | 12.7-13.2 | ≥971 | ≥12.2 | ≥1990 | ≥25 | 310-342 | 39-43 | 180 ℃ |

| 50UH | 1390-1440 | 13.9-14.4 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 374-406 | 47-51 | 180 ℃ |

| 52UH | 1420-1470 | 14.2-14.7 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 390-422 | 49-53 | 180 ℃ |

| 28EH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | 25-28 | 200℃ |

| 30EH | 1080-1130 | 11.3-11.7 | ≥812 | ≥10.2 | ≥2388 | ≥30 | 223-247 | 28-31 | 200℃ |

| 33EH | 1130-1170 | 11.3-11.7 | ≥820 | ≥10.3 | ≥2388 | ≥30 | 247-271 | 31-34 | 200℃ |

| 35EH | 1170-1220 | 11.7-12.2 | ≥836 | ≥10.5 | ≥2388 | ≥30 | 263-287 | 33-36 | 200℃ |

| 28AH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2706 | ≥34 | 207-231 | 25-28 | 230℃ |

| 30AH | 1070-1130 | 10.7-11.3 | ≥812 | ≥10.2 | ≥2706 | ≥34 | 215-247 | 27-31 | 230℃ |

| 33AH | 1110-1170 | 11.1-11.7 | ≥820 | ≥10.3 | ≥2706 | ≥34 | 239-271 | 30-34 | 230℃ |

Detay anbalaj