Custom Neodymium Magnets

Neodymium maganadisu na al'ada bisa ga buƙatun kamfanin ku. Muna sayar da duk maki na neodymium maganadiso, al'ada siffofi, girma da kuma shafi

Neodymium Magnets Manufacturer, masana'antu A kasar Sin

HuizhouFasahar FullzenCo., Ltd kwararre neneodymium maganadisu manufacturer, al'ada maganadisu manufacturer , masana'anta, kuma maroki a china tun 2016. Mu ne na musamman a gwaji, zane, aikin injiniya, masana'antu, dubawa, da kuma hadawa na al'ada neodymium maganadiso. Keɓancewa don biyan buƙatun kamfanin ku. Mun bayar kashe-da-shiryayye kayayyakin, kazalika da musamman ayyuka, al'ada zane na dindindin maganadiso , al'ada siffa neodymium maganadiso , tela yi don masana'antu.

Zaɓi Magnet ɗin Neodymium naku

Neodymium magnet bidiyo

Neodymium maganadisu gabatarwa

Neodymium maganadisu, kuma aka sani da NdFeB maganadisu, wani Tetragonal crystal tsarin crystal kafa ta Nd2Fe14B. Wani abu ne na maganadisu da aka yi daga karfe praseodymium neodymium ta hanyar shiri da sintiri. Irin wannan maganadiso shine maganadisu na dindindin wanda magnetism shine na biyu kawai ga Absolute zero holmium magnet, kuma shine mafi yawan amfani da magnet din Rare-earth.

Neodymium maganadisu sinadaran abun da ke ciki

Neodymium baƙin ƙarfe boron abin maganadisu na dindindin abu ne na maganadisu na dindindin bisa mahaɗin tsaka-tsakin Nd2Fe14B. Babban abubuwan da ke tattare da su sune abubuwan da ba kasafai ba neodymium (Nd), iron (Fe), da boron (B). Babban abin da ba kasafai ake samu ba shi ne neodymium (Nd), wanda za a iya maye gurbinsa da wani bangare da wasu karafa da ba kasafai ba kamar su dysprosium (Dy) da praseodymium (Pr) don samun kadarori daban-daban. Hakanan ana iya maye gurbin baƙin ƙarfe da wasu karafa kamar cobalt (Co) da aluminum (Al). Abubuwan da ke cikin boron kaɗan ne, amma yana taka muhimmiyar rawa wajen samar da tsarin tetragonal crystal tsarin intermetallic mahadi, yin mahadi suna da babban jikewa magnetization, high uniaxial anisotropy, da kuma high Curie zafin jiki.

Neodymium maganadiso Tsarin tafiyar matakai

Tsarin tsari:batching → narkewa da ingot yin / tsiri jifa → yin foda → gyare-gyare → sintering da tempering → Magnetic gwajin → nika sarrafa → fil yankan sarrafa → electroplating → gama samfurin. Sinadaran su ne tushe, kuma sintering da tempering su ne mabuɗin.

Kayan aikin samarwa da kayan aikin gwajin aiki don neodymium iron boron magnet blanks:ciki har da narke tanderu, tsiri amai makera, murkushe inji, airflow niƙa, matsawa gyare-gyaren, injin marufi inji, isostatic latsa inji, sintering makera, zafi magani injin makera, Magnetic yi gwajin, Gaussian mita.

Neodymium iron boron magnet machining kayan aikin:nika mara tsakiya, na'ura mai zagaye, niƙa ƙarshen niƙa, niƙa lebur, injin slicing, niƙa mai gefe biyu, yankan waya, rawar benci, niƙa mara kyau, da sauransu.

Neodymium maganadisu aikace-aikace

Sintered neodymium baƙin ƙarfe boron m maganadisu kayan da kyau kwarai Magnetic Properties kuma ana amfani da ko'ina a filayen kamar Electronics, ikon inji, likita kayan aiki, toys, marufi, hardware kayan, Aerospace, da dai sauransu Common wadanda hada da m maganadisu Motors, jawabai, Magnetic separators, kwamfuta faifai tafiyarwa, Magnetic rawa Dabarar kayan aiki kida, da dai sauransu.

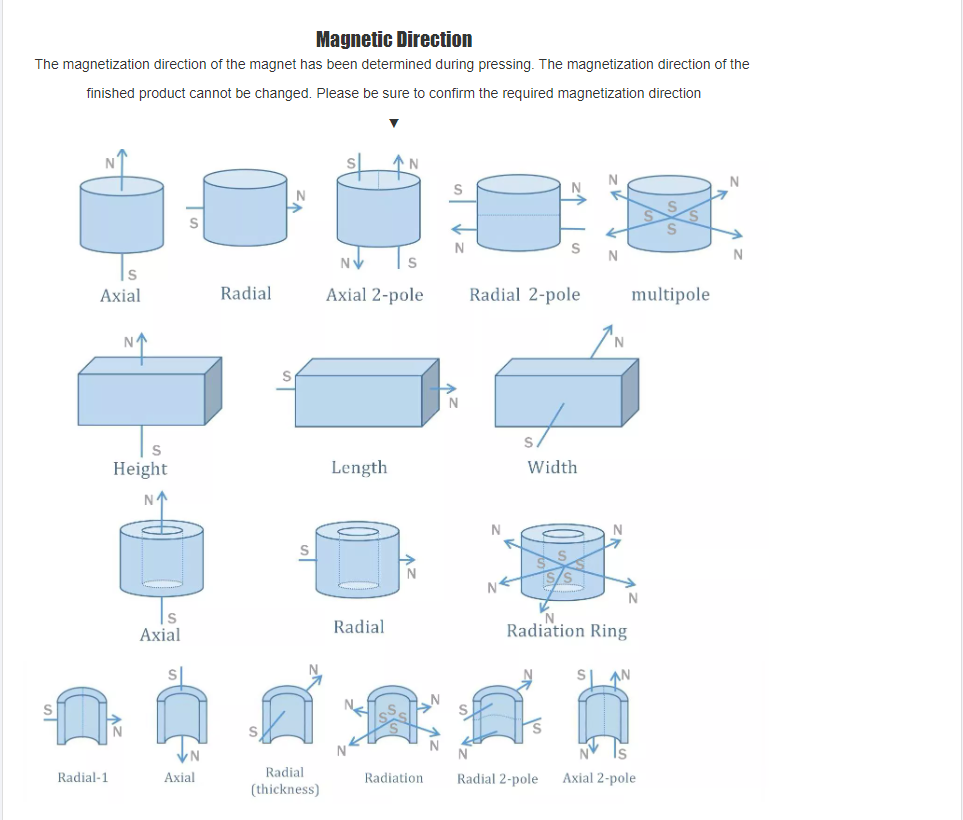

Neodymium maganadiso maganadisu shugabanci da kumashafi na saman

An kasa samun abin da kuke nema?

Gabaɗaya, akwai hannun jari na gama gari neodymium ko albarkatun ƙasa a cikin ma'ajin mu. Amma idan kuna da buƙatu na musamman, muna kuma ba da sabis na keɓancewa. Muna kuma karɓar OEM/ODM.

Custom Neodymium Magnets

HuizhouFasahar FullzenCo., Ltd ne kwararren maganadisu manufacturer.Our kamfanin al'ada rare duniya maganadiso da kuma daya daga saman al'ada maganadisu manufacturers.We ne na musamman a gwaji, zane, aikin injiniya, masana'antu, dubawa da kuma hadawa naal'ada neodymium maganadiso. Keɓancewa don biyan buƙatun kamfanin ku.Kamar yadda jagorar al'ada mai zuwa ke nunawa, muna siyar da cikakkiyar maganadisu neodymium. Muna ba da samfuran kashe-kashe da kuma ayyuka na musamman, maganadisu na dindindin na al'ada , wanda aka yi don masana'antar ku.Kamar manyan abubuwan maganadiso neodymium arc da aka keɓance muku.

Girma da siffa:

Za mu iya samar da na musammandiski, silinda, zobe, square cube, rectangular block, arc, countersunk, ƙugiya da sauran abubuwan maganadisu na dindindin marasa tsari.

Kera:

Muna amfani da atomatikkayan aikidon yankewa da niƙa albarkatun ƙasa don yin ma'auni na magnet ɗin dindindin da kuke so, tare da ƙananan haƙuri, don cimma sakamako na ƙarshe.

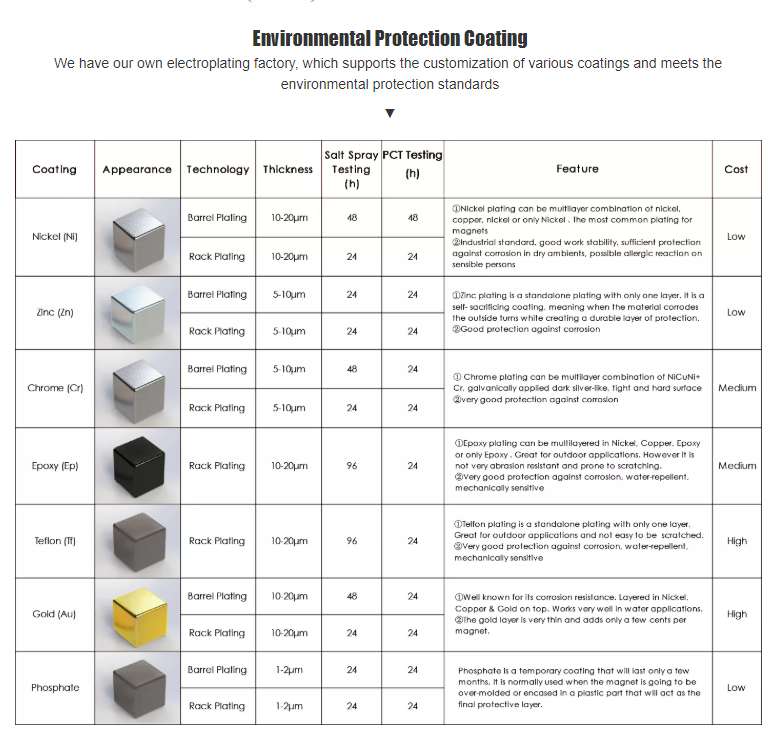

Maganin saman:

Abubuwan maganadisu na dindindin suna da sauƙin zama oxidized. Dangane da buƙatun abokin ciniki, za a rufe farfajiyar, mai rufin epoxy ko lantarki don hana lalata. Za mu iya samar da nickel plating, galvanization, electrophoresis da sauran ayyuka.

Bayanan Zazzabi:

Magnet na dindindin yana kula da yanayin zafi. Za mu tsananin samar bisa ga abokin ciniki ta bukatar ga m maganadiso tare da high zafin jiki juriya.

Jagoran al'ada

| Kayan abu | Sintered Neodymium-Iron-Boron (NdFeB) | |

| Girman | Custom | |

| Siffar | Bkulle,Disc,Cylinder,Bar,Ring, Cauntersunk, BangareHyayi,Csama,Trazoid, Isiffofi na yau da kullum, da dai sauransu. | |

| Ayyuka | N33 N35 N38 N40 N42 N45 N48 N50 N52N54 da sauransu. | |

| Tufafi | Zn, Ni-Cu-Ni, Ni, Zinariya, Azurfa, Copper, Epoxy, Chrome, da sauransu | |

| Haƙuri girma | ± 0.05mm don diamater / kauri, ± 0.1mm don nisa / tsayi | |

| Magnetization | Kauri Magnetized, Axially Magnetized, Diamitrally Magnetized, Multi-sanduna magnetized, Radial Magnetized. (Maganin buƙatun da aka keɓance magnetized) | |

| Max. Yanayin Aiki | Daraja | Max. Yanayin Aiki |

| N35-N52 | 80°C (176°F) | |

| 33M-48M | 100°C (212°F) | |

| 33H-48H | 120°C (248°F) | |

| 30SH-45SH | 150°C (302°F) | |

| Saukewa: 30UH-40UH | 180°C (356°F) | |

| Saukewa: 28EH-38 | 200°C (392°F) | |

| 28AH-35AH | 220°C (428°F) | |

MOQ & Lokacin Jagoranci

| Guda-guda | Lokacin Jagora |

| 1000-10000 | Kwanaki 10 |

| 10000-100000 | Kwanaki 20 |

| 100000-100000 | Kwanaki 30 |

Abin da za mu iya ba ku…

Mu ƙwararrun masana'antun Neodymium Magnet ne kuma masu siyarwa a China. Za mu iya samar da Neodymium Magnet (NdFeB magnet) bisa ga bukatun ku.

Ayyukan Magnet

Akwai galibin sigogin ayyuka guda uku masu zuwa don tantance aikin maganadisu:

Remanence Br: Bayan Magnetic na dindindin ya zama magnetized zuwa jikewar fasaha kuma an cire filin maganadisu na waje, abin da ke riƙe da shi ana kiransa ragowar maganadisu.

Ƙarfin Ƙarfin Ƙarfi Hc: Don rage B na maganadisu na dindindin magnetized zuwa jikewar fasaha zuwa sifili, abin da ake buƙata ƙarfin filin maganadisu ana kiransa ƙarfin ƙarfin shigar da maganadisu, an rage shi azaman ƙarfin tilastawa.

Samfurin makamashi na Magnetic BH: Yana wakiltar ƙarfin ƙarfin maganadisu da magnet ya kafa a cikin sararin ratar iska (sarari tsakanin igiyoyin maganadisu biyu na maganadisu), wato, ƙarfin magnetostatic na kowane juzu'i na ratar iska. Tunda wannan makamashi yayi daidai da samfurin Magnet's Bm da Hm, ana kiransa samfurin makamashin maganadisu.

Za mu iya siffanta maganadisu na dindindin tare da kaddarorin tsakaninN35-N54a kasuwa.

Siga na Magnets

| Daraja | Kasancewa | Karfin Tilastawa | Ƙarfin Ƙarfin Ƙarfi na ciki | Matsakaicin Samfuran Makamashi | Yanayin Aiki | ||||

| Br | Hcb | Hcj | BH max | Tw | |||||

| mT | KGs | ka/m | ku | ka/m | ku | kJ/m3 | MGOe | ||

| N35 | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥955 | ≥12 | 263-287 | 33-36 | 80 ℃ |

| N38 | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥955 | ≥12 | 287-310 | 36-39 | 80 ℃ |

| N40 | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥955 | ≥12 | 302-326 | 38-41 | 80 ℃ |

| N42 | 1280-1320 | 12.8-13.2 | ≥923 | ≥11.6 | ≥955 | ≥12 | 318-342 | 40-43 | 80 ℃ |

| N45 | 1320-1370 | 13.2-13.7 | ≥876 | ≥11.0 | ≥955 | ≥12 | 342-366 | 43-46 | 80 ℃ |

| N48 | 1370-1420 | 13.7-14.2 | ≥892 | ≥11.2 | ≥955 | ≥12 | 366-390 | 46-49 | 80 ℃ |

| N50 | 1390-1440 | 13.9-14.4 | ≥836 | ≥ 10.5 | ≥955 | ≥12 | 374-406 | 47-51 | 80 ℃ |

| N52 | 1420-1470 | 14.2-14.7 | ≥836 | ≥ 10.5 | ≥876 | ≥11 | 390-422 | 49-53 | 80 ℃ |

| N55 | 1460-1520 | 14.6-15.2 | ≥716 | ≥9 | ≥876 | ≥11 | 414-446 | 52-56 | 80 ℃ |

| 35M | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1114 | ≥14 | 263-287 | 33-36 | 100 ℃ |

| 38M | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1114 | ≥14 | 287-310 | 36-39 | 100 ℃ |

| 40M | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1114 | ≥14 | 302-326 | 38-41 | 100 ℃ |

| 42M | 1280-1320 | 12.8-13.2 | ≥995 | ≥ 12.0 | ≥1114 | ≥14 | 318-342 | 40-43 | 100 ℃ |

| 45M | 1320-1370 | 13.2-13.7 | ≥995 | ≥12.5 | ≥1114 | ≥14 | 342-366 | 43-46 | 100 ℃ |

| 48M | 1360-1420 | 13.6-14.2 | ≥1019 | ≥12.8 | ≥1114 | ≥14 | 366-390 | 46-49 | 100 ℃ |

| 50M | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1114 | ≥14 | 374-406 | 47-51 | 100 ℃ |

| Miliyan 52 | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1035 | ≥13 | 390-422 | 49-53 | 100 ℃ |

| 33H | 1130-1170 | 11.3-11.7 | ≥836 | ≥ 10.5 | ≥1353 | ≥17 | 247-271 | 31-34 | 120 ℃ |

| 35H | 1170-1220 | 11.7-12.2 | ≥868 | ≥10.9 | ≥1353 | ≥17 | 263-287 | 33-36 | 120 ℃ |

| 38H | 1220-1250 | 12.2-12.5 | ≥899 | ≥11.3 | ≥1353 | ≥17 | 287-310 | 36-39 | 120 ℃ |

| 40H | 1250-1280 | 12.5-12.8 | ≥923 | ≥11.6 | ≥1353 | ≥17 | 302-326 | 38-41 | 120 ℃ |

| 42H | 1280-1320 | 12.8-13.2 | ≥955 | ≥ 12.0 | ≥1353 | ≥17 | 318-342 | 40-43 | 120 ℃ |

| 45H | 1320-1370 | 13.2-13.7 | ≥971 | ≥12.2 | ≥1353 | ≥17 | 342-366 | 43-46 | 120 ℃ |

| 48H ku | 1360-1420 | 13.6-14.2 | ≥1027 | ≥12.9 | ≥1353 | ≥17 | 366-390 | 46-49 | 120 ℃ |

| 50H | 1390-1440 | 13.9-14.4 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 374-406 | 47-51 | 120 ℃ |

| 52H | 1420-1470 | 14.2-14.7 | ≥1035 | ≥13.0 | ≥1274 | ≥16 | 390-422 | 49-53 | 120 ℃ |

| 28SH | 1040-1090 | 10.4-10.9 | ≥780 | ≥9.8 | ≥1592 | ≥20 | 207-231 | 25-28 | 150 ℃ |

| 30SH | 1080-1130 | 11.3-11.7 | ≥804 | ≥ 10.1 | ≥1592 | ≥20 | 223-247 | 28-31 | 150 ℃ |

| 33SH | 1130-1170 | 11.3-11.7 | ≥844 | ≥10.6 | ≥1592 | ≥20 | 247-271 | 31-34 | 150 ℃ |

| 35SH | 1170-1220 | 11.7-12.2 | ≥876 | ≥11 | ≥1592 | ≥20 | 263-287 | 33-36 | 150 ℃ |

| 38SH | 1220-1250 | 12.2-12.5 | ≥907 | ≥ 10.5 | ≥1592 | ≥20 | 287-310 | 36-39 | 150 ℃ |

| 40SH | 1250-1280 | 12.5-12.8 | ≥939 | ≥11.8 | ≥1592 | ≥20 | 302-326 | 38-41 | 150 ℃ |

| 42SH | 1280-1320 | 12.8-13.2 | ≥971 | ≥12.2 | ≥1592 | ≥20 | 318-342 | 40-43 | 150 ℃ |

| 45SH | 1320-1370 | 13.2-13.7 | ≥979 | ≥12.3 | ≥1592 | ≥20 | 342-366 | 43-46 | 150 ℃ |

| 50SH | 1390-1440 | 13.9-14.4 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 374-406 | 47-51 | 150 ℃ |

| 52SH | 1420-1470 | 14.2-14.7 | ≥995 | ≥12.5 | ≥1592 | ≥19 | 390-422 | 49-53 | 150 ℃ |

| 28 UH | 1020-1080 | 10.2-10.8 | ≥764 | ≥9.6 | ≥1990 | ≥25 | 207-231 | 25-28 | 180 ℃ |

| 33 UH | 1130-1170 | 11.3-11.7 | ≥812 | ≥ 10.2 | ≥1990 | ≥25 | 247-271 | 31-34 | 180 ℃ |

| 35UH | 1170-1220 | 11.7-12.2 | ≥852 | ≥10.7 | ≥1990 | ≥25 | 263-287 | 33-36 | 180 ℃ |

| 38 UH | 1220-1250 | 12.2-12.5 | ≥860 | ≥10.8 | ≥1990 | ≥25 | 287-310 | 36-39 | 180 ℃ |

| 40UH | 1250-1280 | 12.5-12.8 | ≥876 | ≥11.0 | ≥1990 | ≥25 | 302-326 | 38-41 | 180 ℃ |

| 42UH | 1270-1320 | 12.7-13.2 | ≥971 | ≥12.2 | ≥1990 | ≥25 | 310-342 | 39-43 | 180 ℃ |

| 50UH | 1390-1440 | 13.9-14.4 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 374-406 | 47-51 | 180 ℃ |

| 52UH | 1420-1470 | 14.2-14.7 | ≥899 | ≥11.3 | ≥1990 | ≥25 | 390-422 | 49-53 | 180 ℃ |

| 28EH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2388 | ≥30 | 207-231 | 25-28 | 200 ℃ |

| 30EH | 1080-1130 | 11.3-11.7 | ≥812 | ≥ 10.2 | ≥2388 | ≥30 | 223-247 | 28-31 | 200 ℃ |

| 33 EH | 1130-1170 | 11.3-11.7 | ≥820 | ≥ 10.3 | ≥2388 | ≥30 | 247-271 | 31-34 | 200 ℃ |

| 35 EH | 1170-1220 | 11.7-12.2 | ≥836 | ≥ 10.5 | ≥2388 | ≥30 | 263-287 | 33-36 | 200 ℃ |

| 28AH | 1020-1080 | 10.2-10.8 | ≥780 | ≥9.8 | ≥2706 | ≥34 | 207-231 | 25-28 | 230 ℃ |

| 30AH | 1070-1130 | 10.7-11.3 | ≥812 | ≥ 10.2 | ≥2706 | ≥34 | 215-247 | 27-31 | 230 ℃ |

| 33 AH | 1110-1170 | 11.1-11.7 | ≥820 | ≥ 10.3 | ≥2706 | ≥34 | 239-271 | 30-34 | 230 ℃ |

Cikakkun bayanai