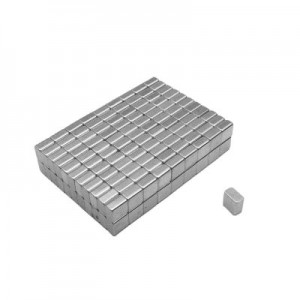

Super Strong Neodymium Magnet Cubes OEM Permanent Magnet | Fullzen Technology

Short Description:

Neodymium block magnets are one of the shapes of neodymium magnets. Because they are cubes, they are also called Rubik’s Cube magnets. As we all know, neodymium magnets are currently the most magnetic magnets, so cube magnets are also widely used in many fields.

Fullzen is one of the China neodymium magnet factory specialized in producing permanent neodymium magnets, and we have produced neodymium magnets n54 cube. We can provide customers with favorable price, high quality neodymium magnets. Please don’t hesitate to consult professional staff to help you solve the problem immediately. Discuss the charm of magnets with Fullzen!

Product Detail

Company profile

Product Tags

Neodymium Ring Magnets

Sintered NdFeB permanent magnets have been constantly breaking new records in the continuous development of these years, and the variety and grades of materials have also continued to increase. With the expansion of the market, the number of production enterprises is also increasing. There are several aspects to judge the advantages and disadvantages of the product: the performance of the magnet: the raw materials must be purchased according to the raw material composition stipulated in the national standard to make the corresponding magnet; the size of the magnet, the coating of the magnet . In this process, neodymium magnets must be produced strictly in accordance with the quality system.

Through our understanding of customer data and industry, permanent magnets are widely used in the following fields: computer hard disk, nuclear magnetic resonance imaging, electric vehicles, wind power generation, industrial permanent magnet motors, consumer electronics, magnetic machines, magnetic separation technology and magnetic transmission, etc. industry.

We sell all grades of strong neodymium ring magnets, custom shapes, sizes, and coatings.

Fast Global Shipping: Meet standard air and sea secure packing, More than 10 years of export experience

Customized is Available: Please offer a drawing for your special design

Affordable Price: Choosing the most suitable quality of products means effective cost savings.

FAQ

The coatings on neodymium magnets are usually thin and designed to protect the magnets from moisture and oxidation in normal indoor environments. They may offer some resistance to light splashes or humidity, but they are not intended for prolonged exposure to water or immersion.

Magnetizing a cube magnet, particularly neodymium magnets, typically requires specialized equipment and processes that are best performed during the manufacturing stage. Magnetizing a magnet involves exposing it to a strong external magnetic field to align its internal magnetic domains. Here's a general overview of the process:

- Magnetization Equipment

- Orientation

- Pulse or Continuous Magnetization

- Demagnetization and Quality Control

Certainly! Cube magnets have a variety of uses across different applications. Here are three ways you can use cube magnets:

- Magnetic Holders and Closures

- Magnetic Assemblies and Devices

- Science

Your Custom Custom Neodymium Magnets Project

Fullzen Magnetics has more than 10 years of experience in the design and manufacture of custom rare earth magnets. Send us a request for quote or contact us today to discuss your project's specialty requirements, and our experienced team of engineers will help you determine the most cost effective way of providing you with what you need.Send us your specifications detailing your custom magnet application.